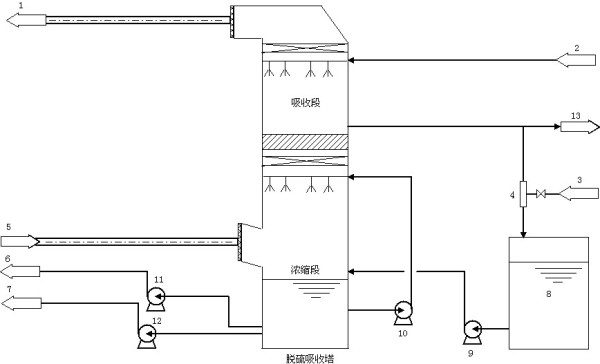

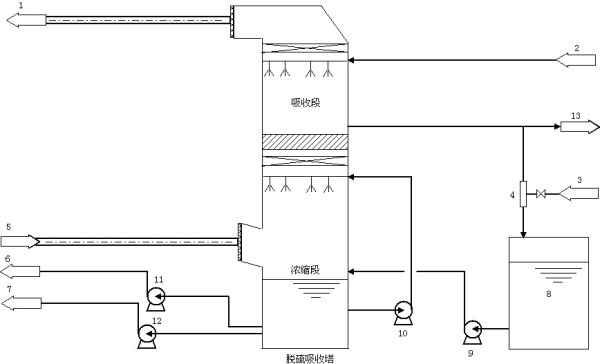

Wet ammonia desulfurization concentration process of cold and hot state discharge

A kind of ammonia desulfurization and process technology, which is applied in the field of wet ammonia desulfurization concentration process, can solve the problems of increasing energy consumption, ammonia escape, increasing the load in the tower, etc., and achieves the reduction of ammonia escape rate, high desulfurization efficiency, and high desulfurization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] As can be seen from the definition of the above process and control and the hot and cold state discharge mode, it is necessary to control the pH value, density and solid content of the concentrated solution, but it is impossible to adjust the pH value by adding ammonia in the concentrated solution, so the present invention By adding liquid ammonia in the oxidation tank to adjust the pH value of the oxidizing solution, the pH value of the concentrated solution is indirectly controlled, and the density adjustment is mainly regulated and controlled by the coordinated control of the concentrated solution circulation pump, the concentrated solution discharge pump and the oxidized solution discharge pump. The control of the solid content is controlled by the choice of the discharge method.

[0027] (1) Control of the pH value of the concentrate

[0028] The main components of the concentrate are ammonium sulfate, part of ammonium bisulfate and a small amount of ammonia water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com