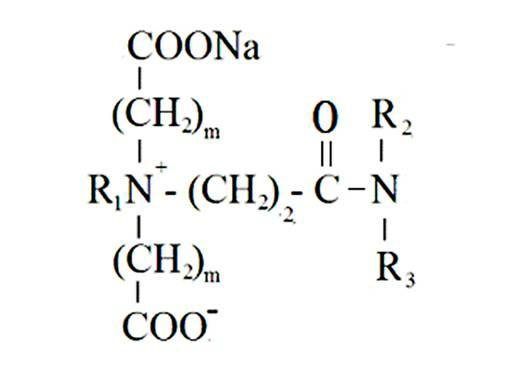

N,N-dialkyl propanamide fatty alkyl betaine amphoteric surfactant, preparation method and application thereof in tertiary recovery

A technology of dialkylpropionamide and surfactant, applied in tertiary oil recovery, N,N-dialkylpropionamide fatty alkyl betaine amphoteric surfactant, auxiliary agent field, can solve complex composition, Oil well scrapping, capillary channel blockage and other problems, to achieve good temperature resistance and salt resistance, high interface activity, and low environmental toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

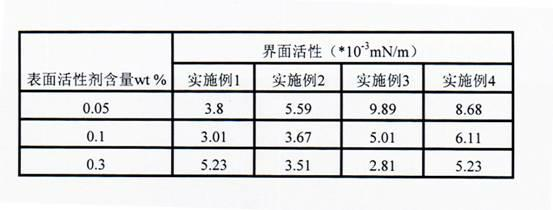

Examples

Embodiment 1

[0014] The mixture of 62.85 grams of hexadecyl primary amine and octadecyl primary amine is put into four-necked flask, (wherein hexadecyl primary amine accounts for 35wt%, and octadecyl primary amine accounts for 65 wt %), heats up When the temperature reaches 80°C, use a dropping funnel to slowly drop 30 grams of N,N-dimethylacrylamide into it, and finish the reaction after 7 hours to generate N,N-dimethylpropionamide cetearyl secondary amine , Put it in a beaker, heat it a little, keep it in liquid state, and get it when you use it.

[0015] Put 17.12 grams of chloroacetic acid into a four-necked flask, weigh 60. grams of water and divide it into two equal parts, add a portion of 40 grams into the four-necked flask, stir to dissolve the chloroacetic acid, then weigh 7.55 grams of sodium hydroxide, and use the remaining Dissolve 20 grams of water, prepare an aqueous solution, pour it into a four-necked bottle, stir and react for 5 minutes, measure the pH value, make it betwe...

Embodiment 2

[0017] The mixture of 62.85 grams of hexadecyl primary amine and octadecyl primary amine is put into four-necked flask, (wherein hexadecyl primary amine accounts for 35wt%, and octadecyl primary amine accounts for 65wt %), is warming up to At 80°C, use a dropping funnel to slowly drop 30 grams of N,N-dimethylacrylamide into it, and finish the reaction after 7 hours to generate N,N-dimethylpropionamide cetearyl secondary amine. Put it in a beaker, heat it a little, and keep it in a liquid state, and you can get it when you use it.

[0018] Put 35.5 grams of chloropropionic acid into a four-necked flask, weigh 90.09 grams of water and divide it into two equal parts, add a portion of 30 grams into the four-necked flask, stir to dissolve the chloropropionic acid, then weigh 24.5 grams of sodium carbonate, and use the remaining Dissolve 60 grams of water, prepare an aqueous solution, pour it into a four-necked bottle, stir and react for 5 minutes, measure the pH value, make it betw...

Embodiment 3

[0020] Put 48.2 grams of hexadecyl primary amine into a four-necked flask, and when the temperature rises to 70°C, slowly drop 29.7 grams of N,N-dimethylacrylamide into it with a dropping funnel, raise the temperature to 80°C, and react for 5 hours Finally, the reaction is completed to generate N,N-dimethylpropionamide hexadecyl secondary amine, which is put into a beaker and heated slightly to maintain a liquid state for use.

[0021] Put 30.6 grams of chlorobutyric acid into a four-necked flask, weigh 90.06 grams of water and divide it into two equal parts, add a portion of 60 grams into the four-necked flask, stir to dissolve the chlorobutyric acid, then weigh 12 grams of sodium hydroxide, and use Dissolve the remaining 30 grams of water, prepare an aqueous solution, pour it into a four-necked bottle, stir and react for 5 minutes, measure the pH value, make it between 8 and 9, and then weigh 34 grams of N,N-dimethylpropionamide ten times Pour hexaalkyl secondary amine into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com