LiFePO4/C anode material repaired and coated by AlPO4 and preparation method thereof

A technology of positive electrode materials and repair kits, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of high price of pyrrole, influence on the electrochemical performance of materials, poor thermal stability, etc., achieve simple process and improve high temperature cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 100g of LiFePO 4 / C and 1.538g of Al(NO 3 ) 3 9H 2 O powder was dispersed in 200mL of deionized water to prepare Al 3+Concentration of 0.02mol / L suspension, stirred for 30 minutes, and then added dropwise 100mL concentration of 0.04mol / L (NH 4 ) 2 HPO 4 Solution, continue to stir for 60 minutes, filter the obtained suspension, wash the reaction product with deionized water until the pH value of the filtrate is 7, dry the filter cake at 100 ° C for 8 hours, and then under the protection of nitrogen atmosphere, the reaction product Raise the temperature to 650°C at a rate of 1°C / min and keep the temperature constant for 2 hours, then naturally cool to room temperature to obtain a mass fraction of 0.5% AlPO 4 Repair coated LiFePO 4 / C cathode material.

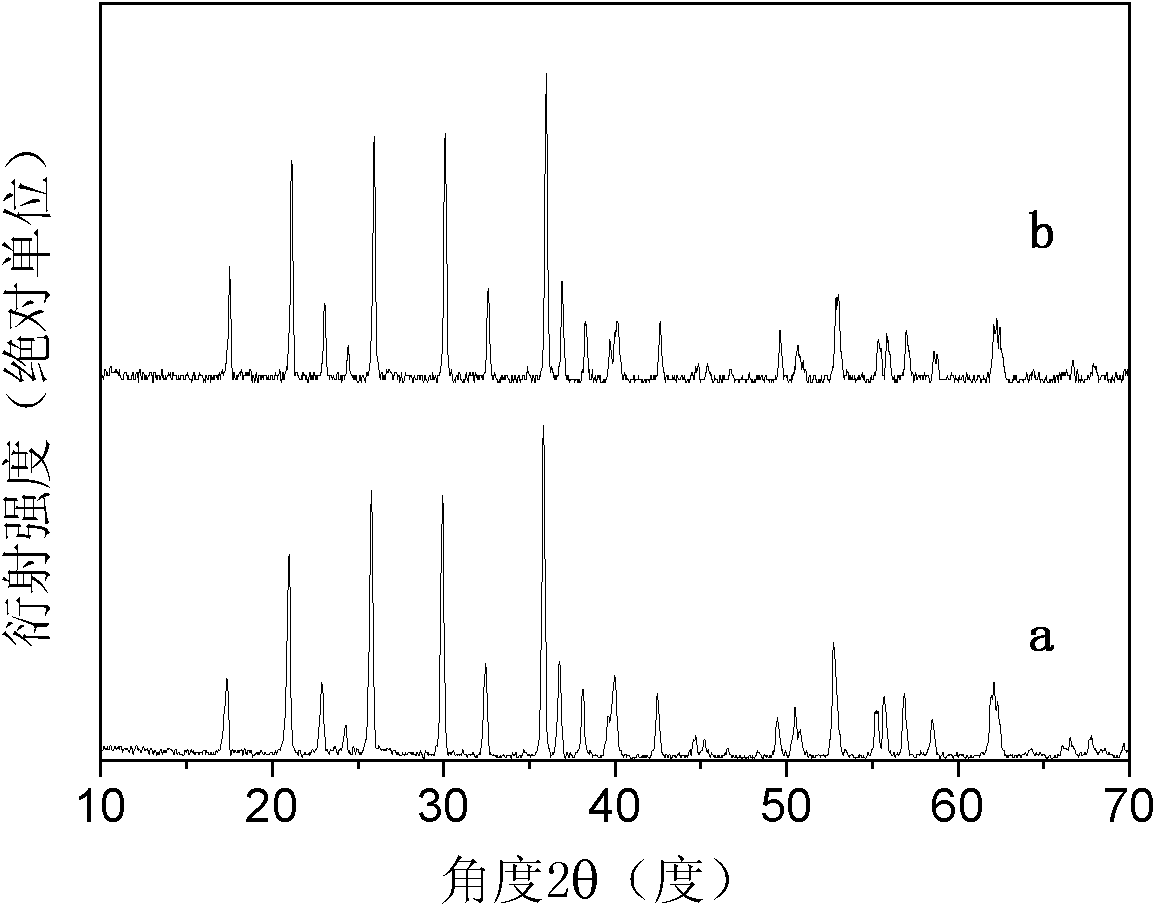

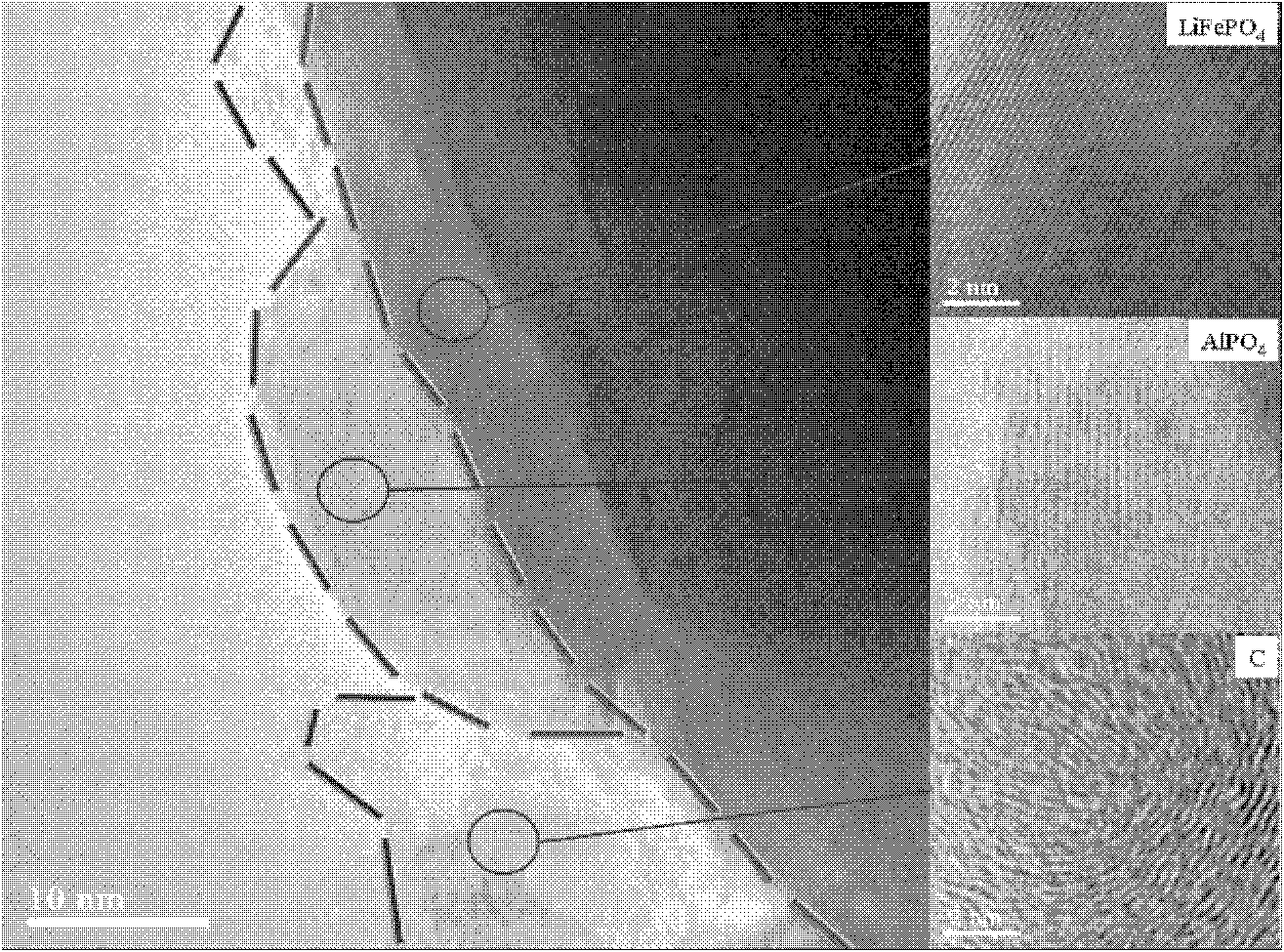

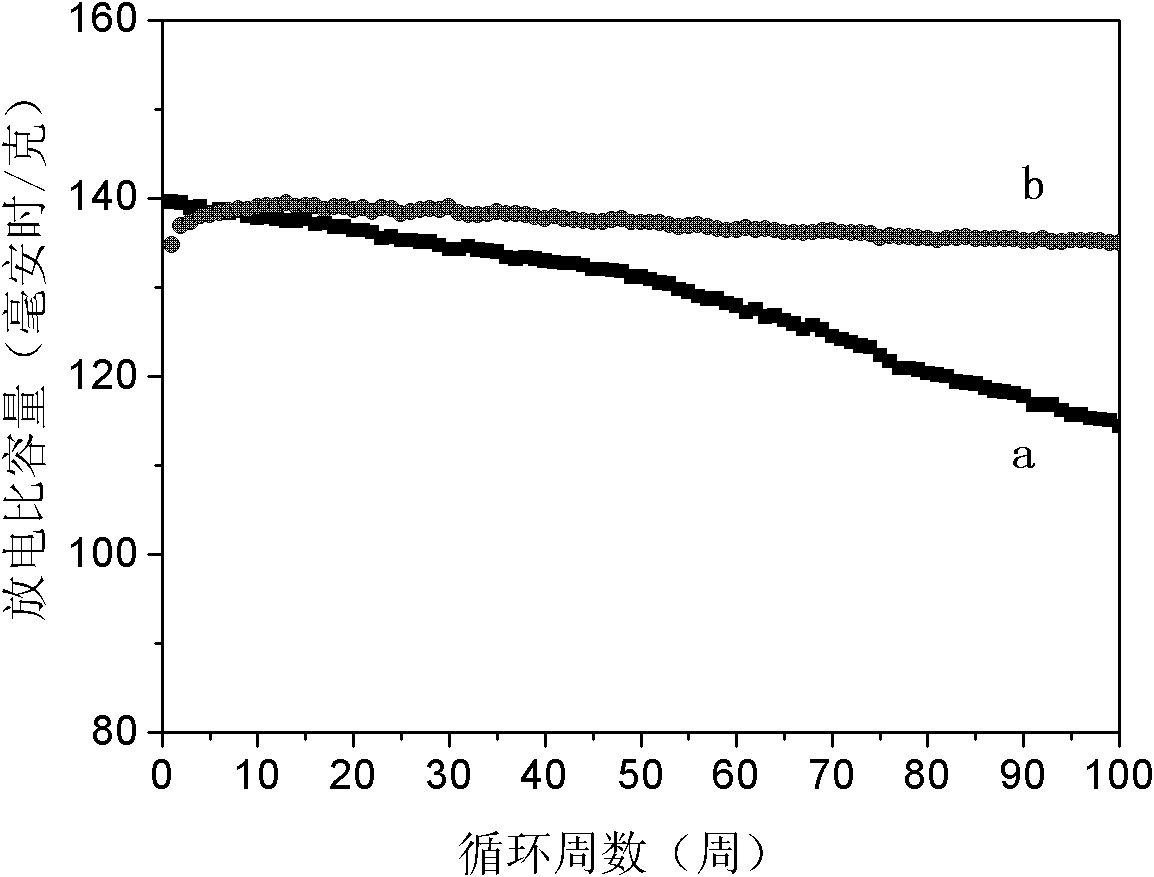

[0022] X-ray powder diffractometer (XRD) was used to analyze LiFePO 4 / C original sample and present embodiment product are characterized, and the result is as follows figure 1 As shown, AlPO 4 Repair coated LiF...

Embodiment 2

[0024] 100g of LiFePO 4 / C and 3.845g of Al(NO 3 ) 3 9H 2 O powder dispersed in 200mL of deionized water, made into Al 3+ Concentration of 0.05mol / L suspension, stirred for 60 minutes, then dropwise added 100mL concentration of 0.125mol / L (NH 4 ) 2 HPO 4 Solution, continue to stir for 30 minutes, filter the obtained suspension, wash the reaction product with deionized water until the pH value of the filtrate is 6.5, dry the filter cake at 50 ° C for 6 hours, and then under the protection of nitrogen atmosphere, the reaction product is Raise the temperature to 500°C at a rate of 10°C / min and keep the temperature constant for 8 hours, then naturally cool to room temperature to obtain a mass fraction of 1.25% AlPO 4 Repair coated LiFePO 4 / C cathode material.

Embodiment 3

[0026] 100g of LiFePO 4 / C and 7.69g of Al(NO 3 ) 3 9H 2 O powder dispersed in 200mL of deionized water, made into Al 3+ The suspension with a concentration of 0.1mol / L was stirred for 90 minutes, and then 100mL of 0.3mol / L (NH 4 ) 2 HPO 4 Solution, continue to stir for 90 minutes, filter the obtained suspension, wash the reaction product with deionized water until the pH value of the filtrate is 7.5, dry the filter cake at 150 ° C for 4 hours, and then under the protection of nitrogen atmosphere, the reaction product is The temperature was raised to 800 °C at a rate of 5 °C / min and kept at a constant temperature for 5 hours, and then naturally cooled to room temperature to obtain a mass fraction of 2.5% AlPO 4 Repair coated LiFePO 4 / C cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com