Nanosecond pulse fiber laser with circle structure

A fiber laser, nanosecond pulse technology, applied in the laser field, can solve the problems of pulse train time jitter and amplitude jitter, pulse width and repetition frequency are not adjustable, and no full fiber is realized, so as to achieve small size and reduce jitter problems. , the effect of suppressing the scattering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

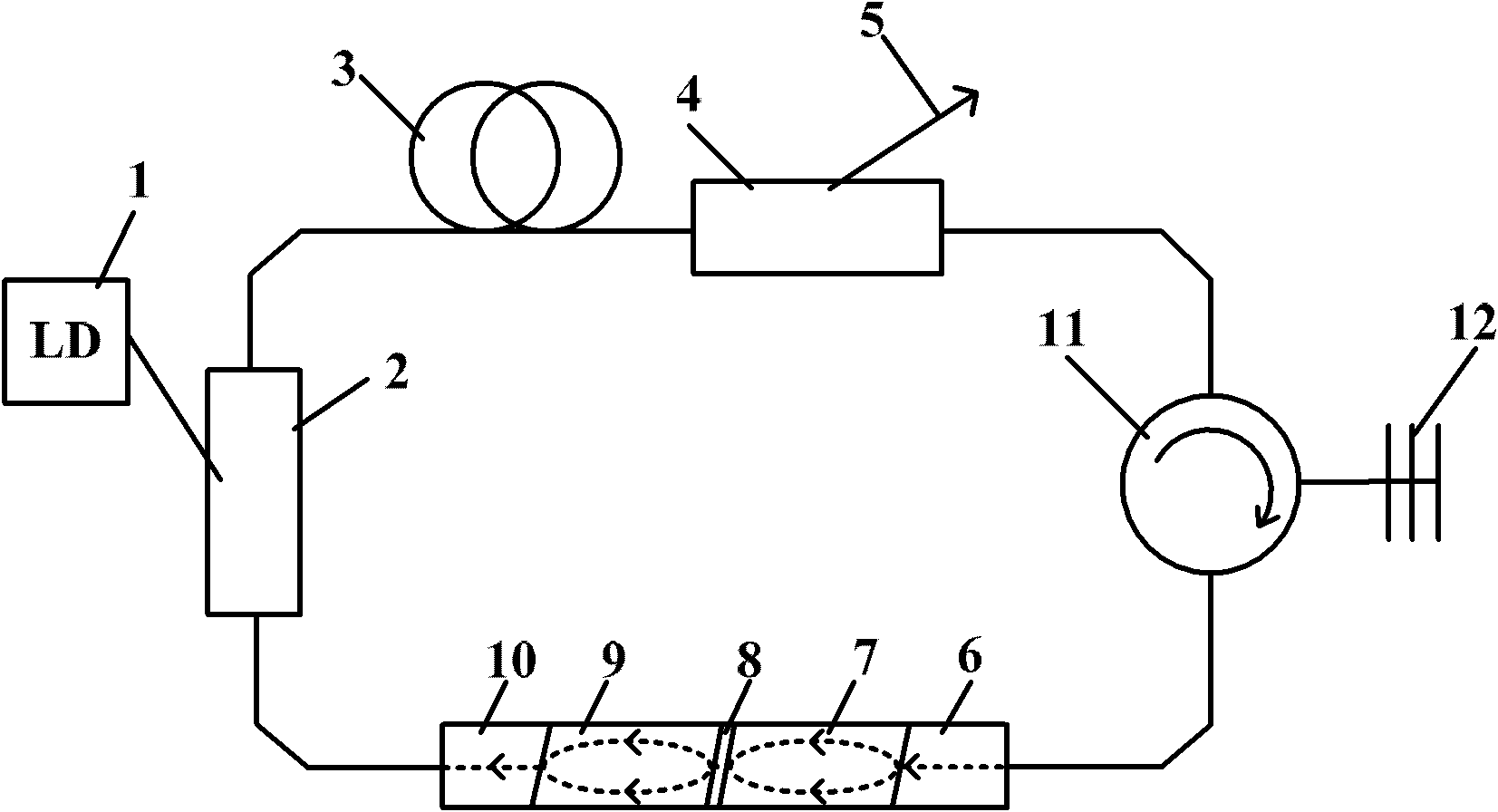

[0023] The first nanosecond pulsed fiber laser with ring structure such as figure 1 shown. figure 1 Among them, 1 is the pump source, which uses a semiconductor laser diode with a maximum withstand power of 10W and a center wavelength of 976nm; 2 is a wavelength division multiplexer, a pump light wavelength division multiplexer with a model of (2+1); 3 is a gain fiber , choose 6m long double-clad ytterbium-doped fiber; 4 is the fiber beam splitter, the splitting ratio is 2:8; 5 is the 20% output end of the fiber beam splitter; 6 and 10 are the first glass sleeve and the second Glass casing, the optical fiber is inserted into the glass casing, so that the laser passes through the glass casing; 7 and 9 are the first self-focusing lens and the second self-focusing lens, the intercept Z of the self-focusing lens is 0.5P, and it adopts double-sided coating , the two end faces are at an angle of 8°, the function is to collimate and focus the laser light entering the glass sleeve; 8...

Embodiment 2

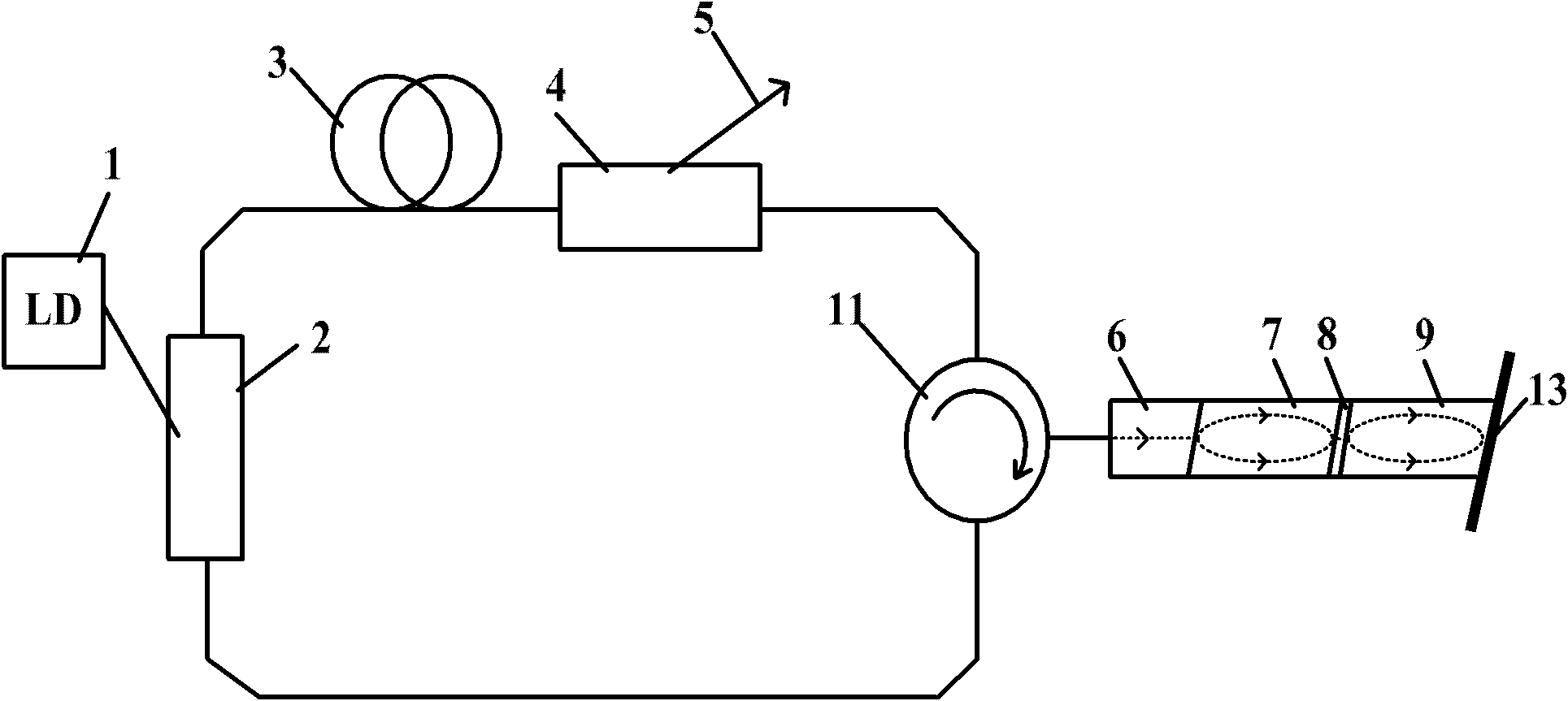

[0026] The second ring structure nanosecond pulsed fiber laser such as figure 2 shown. figure 2 Among them, 1 is the pump source, which uses a semiconductor laser diode with a maximum withstand power of 10W and a center wavelength of 976nm; 2 is a wavelength division multiplexer, a pump light wavelength division multiplexer with a model of (2+1); 3 is a gain fiber , choose 6m long double-clad ytterbium-doped optical fiber; 4 is the optical fiber beam splitter, the splitting ratio is 2:8; 5 is the 20% output end of the optical fiber beam splitter; 6 is the first glass sleeve, and the optical fiber is inserted into the glass sleeve , so that the laser passes through the glass sleeve; 7 and 9 are the first self-focusing lens and the second self-focusing lens, the intercept Z of the self-focusing lens is 0.5P, and the double-sided coating is selected, and the angle of both end faces is 8° , the role is to collimate and focus the laser light entering the glass tube; 8 is a Cr:YA...

Embodiment 3

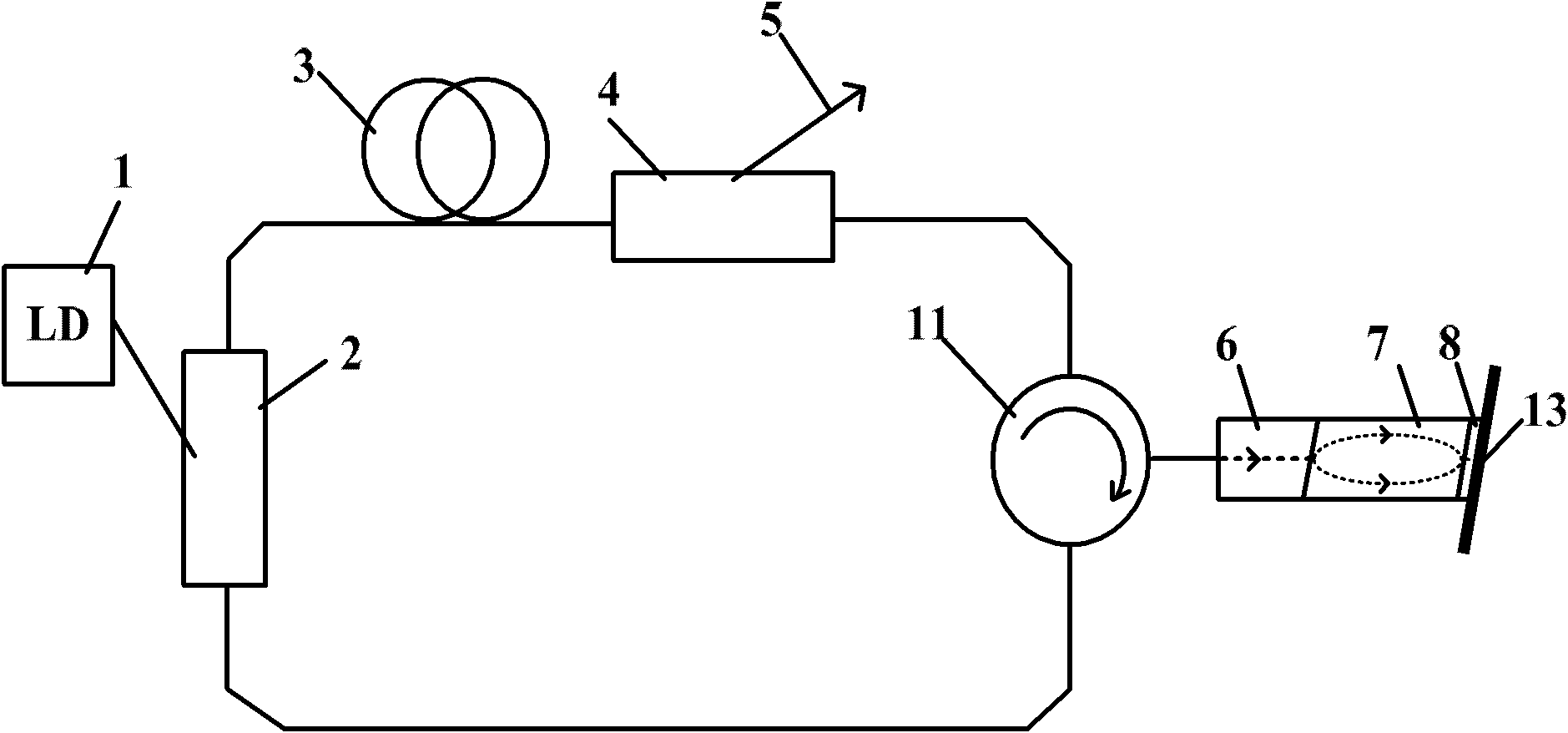

[0029] The third ring structure nanosecond pulsed fiber laser such as image 3 shown. image 3 Among them, 1 is the pump source, which uses a semiconductor laser diode with a maximum withstand power of 10W and a center wavelength of 976nm; 2 is a wavelength division multiplexer, a pump light wavelength division multiplexer with a model of (2+1); 3 is a gain fiber , choose 6m long double-clad ytterbium-doped optical fiber; 4 is the optical fiber beam splitter, the splitting ratio is 2:8; 5 is the 20% output end of the optical fiber beam splitter; 6 is the first glass sleeve, and the optical fiber is inserted into the glass sleeve , make the laser pass through the glass casing; 7 is the first self-focusing lens, the intercept Z of this self-focusing lens=0.5P, select double-sided coating, both end faces are 8° angle, the effect is to enter the glass casing The laser is collimated and focused; 8 is a Cr:YAG saturable absorber, and its diameter Thickness 1 = 2.13mm, transmittan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com