Method for extracting natural antioxidant from shells of camellia oleifera

A natural anti-oxidation and Camellia oleifera husk technology, which is applied in anti-toxic agents, drug combinations, and pharmaceutical formulas, can solve the problems of low utilization rate of Camellia oleifera husk and limited types of raw materials for proanthocyanidin extraction, and achieve strong antioxidant capacity and long extraction time. Short, efficient use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

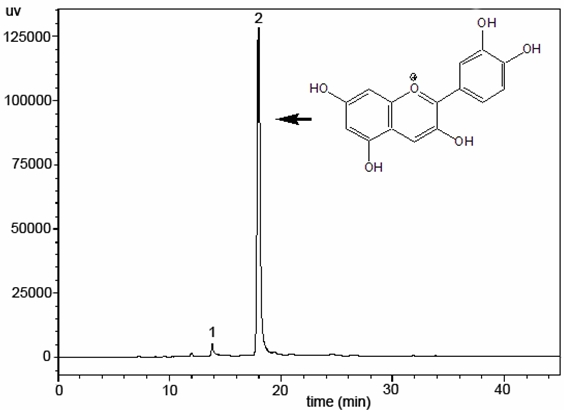

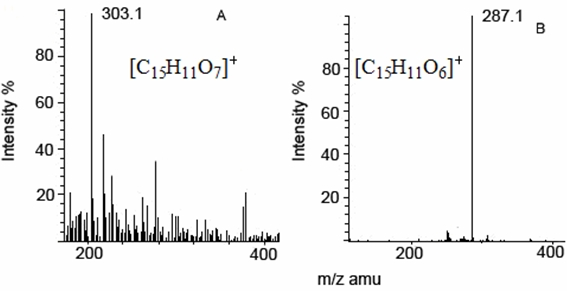

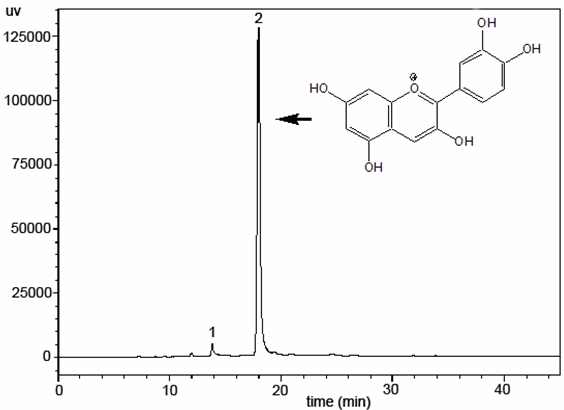

Image

Examples

Embodiment 1

[0033] A method for extracting natural antioxidant substances from camellia oleifera shell:

[0034] (1) Pulverization: Pulverize the purified Camellia oleifera husk raw material with a plant pulverizer (sieve hole Φ=2-4 mm).

[0035] (2) Extraction: using water as solvent, using microwave extraction, the solid-liquid mass volume ratio is 1:15-25, controlling the microwave irradiation temperature at 60-80°C, and the irradiation time for 15-35 min, to obtain the extract; the temperature can be Yes: 60°C, 65°C, 70°C, 75°C, 80°C.

[0036] (3) Centrifugation: The extract was centrifuged at 5000 rpm for 30 min in a centrifuge to separate the supernatant and discard the precipitate.

[0037](4) Resin adsorption separation: put the pre-purified non-polar or low-polar macroporous adsorption resin on the above supernatant, the flow rate of the upper column liquid is 1.4-1.7 Bv / h, and wash the column with pure water after adsorption. Then elute with ethanol aqueous solution with a vol...

Embodiment 2

[0041] (1) Put 50 g of Camellia oleifera husk raw material that has been purified, air-dried and crushed (using a plant pulverizer to pass through a Φ2 mm sieve plate) and 750 mL of pure water into a 1000 mL three-necked flask for microwave extraction and controlled microwave irradiation The temperature was 80°C, and the irradiation time was 35 min to obtain 620 mL of extract.

[0042] (2) After the extract was cooled, it was centrifuged in a centrifuge, set the speed of the centrifuge at 5000 rpm, centrifuged for 30 min, and separated 550 mL of supernatant.

[0043] (3) Add the above supernatant to the pretreated AB-8 type macroporous resin (Bv=265 cm 3 ), and then washed the column with 2.4 Bv / h of pure water, and then eluted with 600 mL of 70% ethanol-water solution at a flow rate of 1.7 Bv / h, and combined the eluents.

[0044] (4) Under normal pressure (1.01×10 5 Pa) Ethanol in the ethanol-water eluent is distilled off (recycled) to obtain a liquid natural antioxidant s...

Embodiment 3

[0047] (1) Put 30 g of Camellia oleifera husk raw material that has been purified, air-dried and crushed (using a plant grinder through a Φ2 mm sieve plate) and 750 mL of pure water into a 1000 mL three-neck flask for microwave extraction and controlled microwave irradiation The temperature was 60°C, and the irradiation time was 35 min to obtain 650 mL of extract.

[0048] (2) After the extract was cooled, it was centrifuged in a centrifuge, set the centrifuge speed at 5000 rpm, centrifuged for 30 min, and separated 580 mL of supernatant.

[0049] (3) Add the above supernatant to the pretreated AB-8 type macroporous resin (Bv=265 cm 3 ), then wash the column with 2.4 Bv / h of pure water, and then elute with 500 mL of 70% ethanol aqueous solution at a flow rate of 1.5 Bv / h, and combine the eluents.

[0050] (4) Under normal pressure (1.01×10 5 Pa) Ethanol in the ethanol-water eluate is evaporated (recycled), and the liquid natural antioxidant substance whose main component is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com