Hole-sealing agent for chemical nickel plating layer and hole-sealing treatment process thereof

A technology of electroless nickel plating layer and treatment process, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problem of insufficient corrosion resistance of the electroless nickel plating layer, and achieve simple hole sealing process, The effect of enhanced corrosion resistance and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

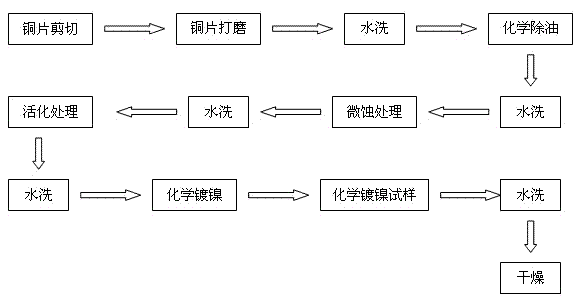

[0050] according to image 3 The flow chart of the sample preparation process of the electroless nickel plating layer is shown to carry out the preparation of the sample of the present invention.

[0051] Prepare a sealing agent with the following composition: add 5% volume of KH-560 to 93% volume of acrylic acid, mix well, then slowly add 2% volume of water, and mix well.

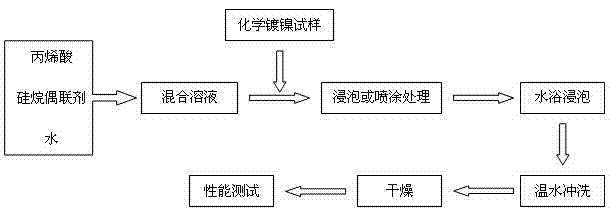

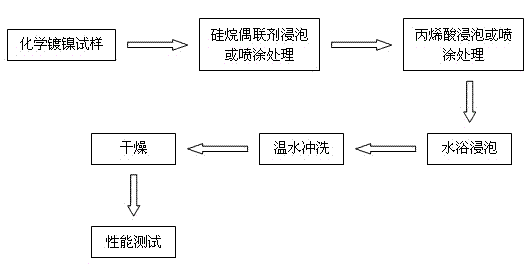

[0052] according to figure 1 The hole-sealing process of the electroless nickel-plated layer sample shown in the present embodiment carries out the hole-sealing process of the electroless nickel-plated layer sample, and the processing conditions of each step are as follows:

[0053] Conditions for immersion treatment of electroless nickel plating layer samples: the temperature is 45°C, and the time is 5 minutes.

[0054] The conditions for the water bath heating treatment of the electroless nickel plating layer sample: the temperature is 85°C, and the time is 3min.

[0055] Conditions for warm water rin...

Embodiment 2

[0057] according to image 3 The flow chart of the sample preparation process of the electroless nickel plating layer is shown to carry out the preparation of the sample of the present invention.

[0058] Prepare a sealing agent with the following composition: add 1% volume of KH-560 to 90% volume of acrylic acid, mix well, then slowly add 9% volume of water, and mix well.

[0059] according to figure 1 The hole-sealing process of the electroless nickel-plated layer sample shown in the present embodiment carries out the hole-sealing process of the electroless nickel-plated layer sample, and the processing conditions of each step are as follows:

[0060] Conditions for immersion treatment of electroless nickel plating layer samples: the temperature is 25°C, and the time is 10 minutes.

[0061] The conditions for the water bath heating treatment of the electroless nickel plating layer sample: the temperature is 90°C, and the time is 1min.

[0062] Conditions for warm water ri...

Embodiment 3

[0064] according to image 3 The flow chart of the sample preparation process of the electroless nickel plating layer is shown to carry out the preparation of the sample of the present invention.

[0065] Prepare a sealing agent with the following composition: add 9% volume of KBM-7103 to 90% volume of acrylic acid, mix well, then slowly add 1% volume of water, and mix well.

[0066] according to figure 1 The hole-sealing process of the electroless nickel-plated layer sample shown in the present embodiment carries out the hole-sealing process of the electroless nickel-plated layer sample, and the processing conditions of each step are as follows:

[0067] Conditions for immersion treatment of the electroless nickel plating layer sample: the temperature is 50°C, and the time is 1min.

[0068] The conditions for the water bath heating treatment of the electroless nickel plating layer sample: the temperature is 70°C, and the time is 5min.

[0069] Conditions for warm water rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com