Method and equipment for collecting carbon dioxide from fuel gas by using ammonia water fine spraying

A carbon dioxide and ammonia water technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve problems such as low carbon dioxide concentration, large flue gas flow, system corrosion, etc., to achieve resource utilization and enhance turbulence degree, the effect of improving the removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The following are only preferred embodiments of the present invention, and the scope of protection of the present invention is not limited thereto. Any changes or changes that can be easily carried out by those skilled in the art within the technical scope disclosed by the present invention are all covered by the scope of the present invention. within the scope of protection. Therefore, the protection scope of the present invention should be determined by the protection scope of the claims.

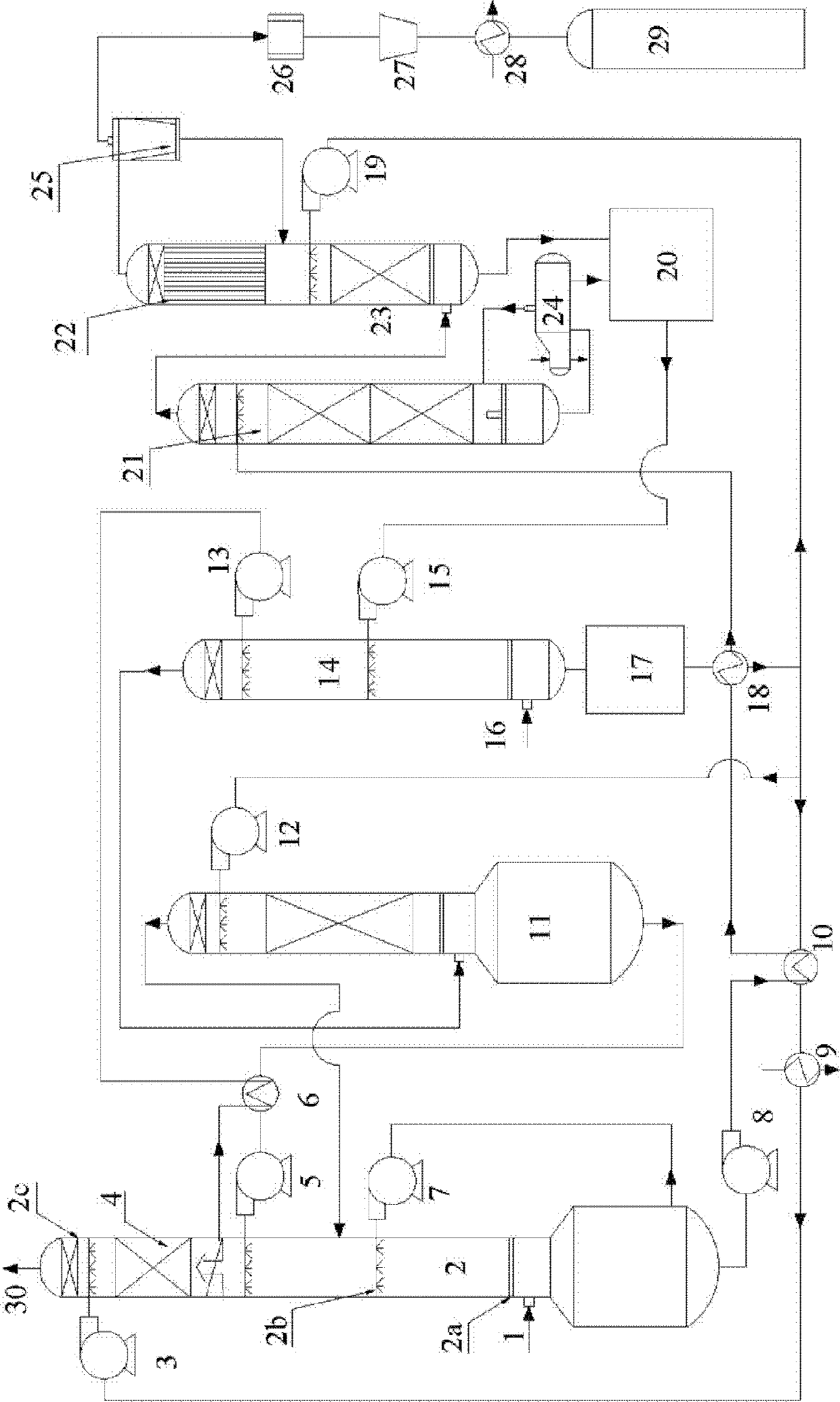

[0037] figure 1 Shown is a device for capturing carbon dioxide in flue gas by a fine spray of ammonia water, which includes an absorption tower 2 connected through pipelines for capturing carbon dioxide, and for desorbing CO 2 Gas desorption tower 21, water washing tower 23 for ammonia removal, reboiler 24 for heating, dilute ammonia water tank 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com