A kind of activated bone charcoal and preparation method thereof

A bone charcoal and active technology, applied in the field of activated bone charcoal and its preparation, can solve the problems of polluting the environment and wasting resources, and achieve the effects of high adsorption performance, simple process and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] Specifically, the application provides a preparation method of activated bone charcoal, which comprises the following steps:

[0016] S1. Drying: Dry the discarded animal bones until the water content is 5-15%.

[0017] S2. Crushing: Crushing the discarded animal bones according to the process requirements.

[0018] S3. Impregnation with an activator: mix the pulverized animal waste bones with an activator and soak for 12-20 hours. Wherein, the mass ratio of the activator to the discarded animal bone is 1.5-3:1, and the activator includes one or more of potassium hydroxide, phosphoric acid, zinc chloride and magnesium chloride.

[0019] By impregnating animal waste bones with activators, usually these activators have dehydration and swelling effects on carbon-containing organic matter, and can fully contact with waste bones, and activate them at a certain temperature (different activators require different temperature ranges) In the process, the activator interacts wi...

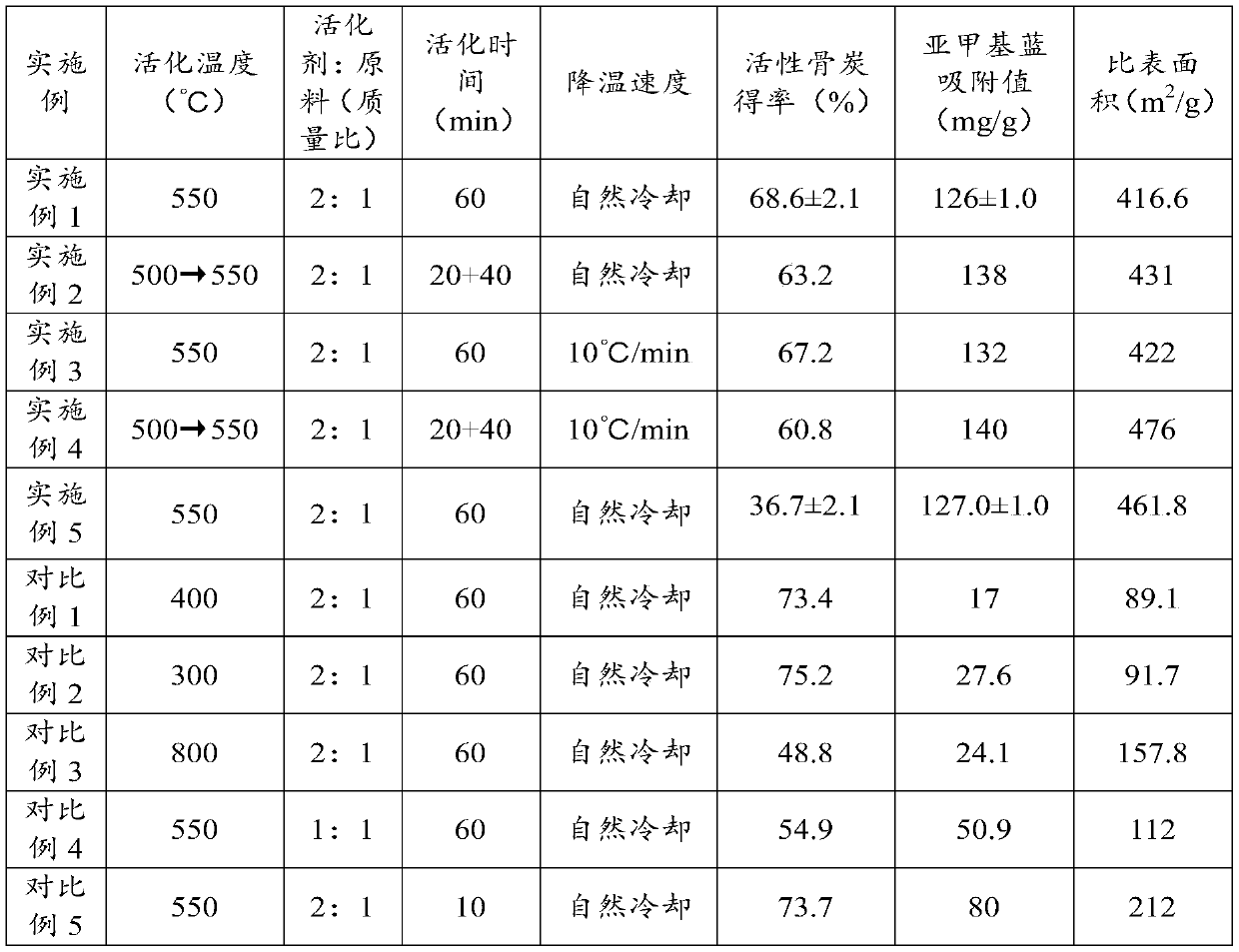

Embodiment 1

[0036] The present embodiment provides a kind of active aggregate (phosphoric acid activated waste pork bone charcoal adsorption material), and its preparation method is as follows:

[0037] Weigh 20 g of waste pig bone raw material and mix with 50 g of phosphoric acid (concentration 85%) activator, and soak for 15 hours. Put the fully impregnated material into a box-type resistance furnace, heat up to 550°C at 20°C / min to activate for 60 minutes, take it out after naturally cooling to room temperature, wash it with water for 5 times, filter it, dry it at 110°C for 10 hours, take it out and grind it 1. After sieving, the prepared powdered activated pig bone charcoal adsorption material sample is packed into a sample bag for subsequent use.

Embodiment 2-5

[0039] Embodiment 2-5 provides a kind of active aggregate (phosphoric acid activated waste pig bone charcoal adsorption material), its preparation method is basically the same as embodiment 1, the difference is:

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com