Environment-friendly glycerol and preparation method thereof

A glycerol and environmental protection technology, applied in the preparation of hydroxyl compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of difficulty in extracting glycerol, limited scope of application of glycerol, complicated equipment, etc., and achieves energy saving in the reaction process, easy operation and preparation The effect of energy saving and environmental protection in the process and low cost of production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

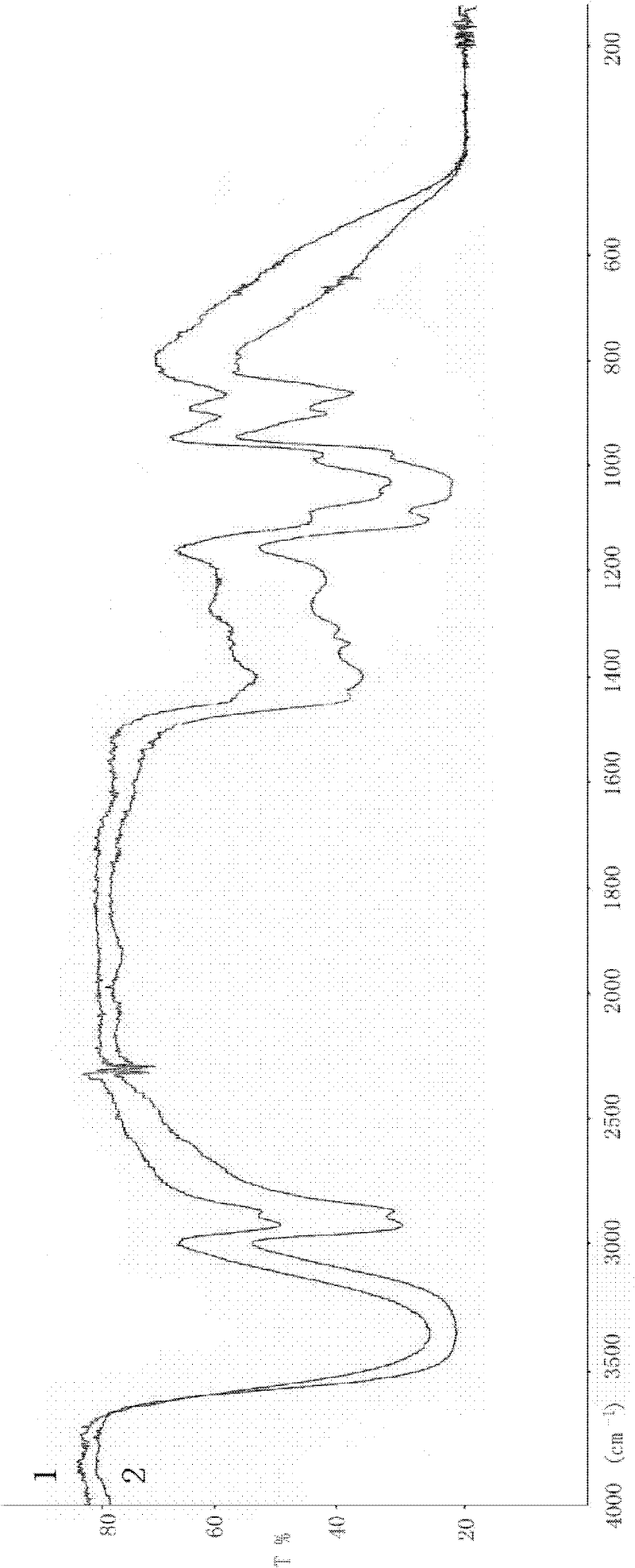

Image

Examples

preparation example Construction

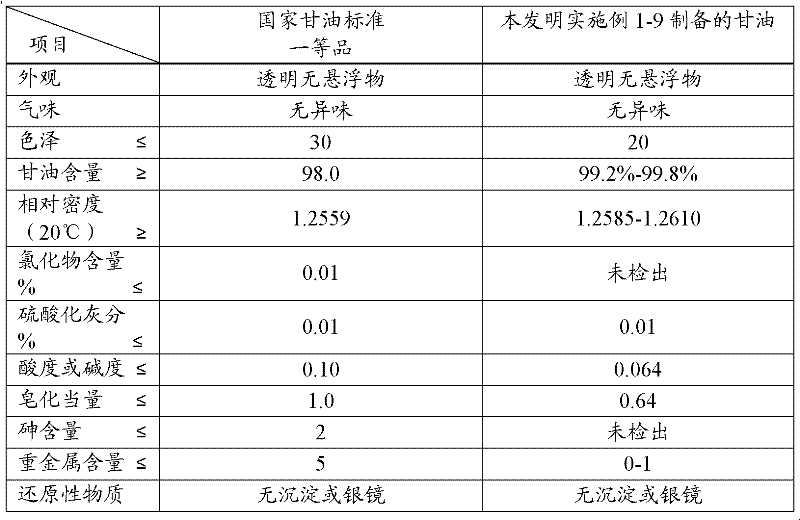

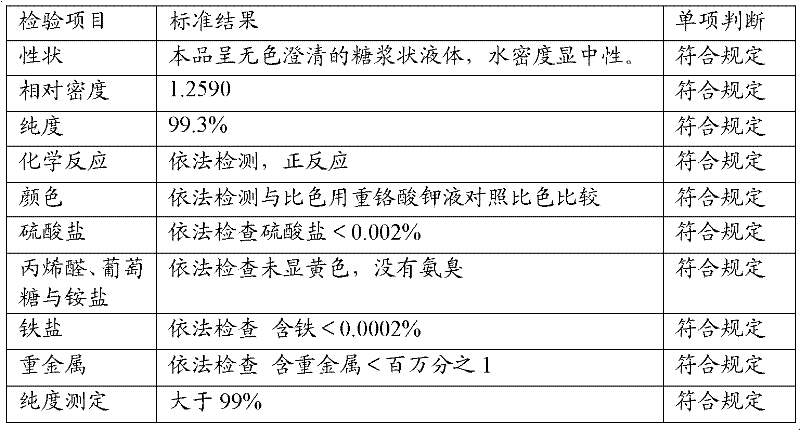

[0027] The invention provides a preparation method of environment-friendly glycerin, that is, sucrose produced by a carbonization process is dissolved into a saturated sugar solution by high-purity water at a certain temperature, and then the saturated sugar solution is reacted with sorbitol at a certain temperature, and then the reaction is carried out at a certain temperature. Several glycols are continuously added to the liquid for stirring reaction. An appropriate amount of antiseptic and decolorizing agent is put in, and the finished glycerin is prepared through the processes of filtration, decolorization and thickening.

[0028] In the present invention, sucrose and sorbitol are mainly used for the preparation of raw materials. Compared with the raw materials used in traditional saponified glycerol, these two raw materials overcome the problem of shortage of raw materials, and the cost is also cheaper. The use of sucrose produced by carbonization rather than sulfurizatio...

Embodiment 1

[0036] Take 260kg of sucrose made by carbonization, add it to a 100kg 5 10 In the reaction kettle 1 of high-purity water, fully stir for 20-60 minutes until the stirring is uniform to obtain a saturated sucrose solution, and control the temperature in the reaction kettle 1 to be about 50° C. during the mixing process.

[0037] The above-mentioned saturated sucrose solution was poured into the reaction kettle 2, and the sorbitol of 390kg was added in the reaction kettle 2, fully stirred for 10-30 minutes until the stirring was uniform and the reaction was complete, and the temperature in the reaction kettle 2 was maintained at 50 °C in the mixing process. ℃ or so.

[0038] Add the ethylene glycol of 90kg and the propylene glycol of 90kg in the reaction kettle 2 that has reacted completely, and the sodium benzoate of 2kg is fully stirred for 40-80 minutes until stirring is homogeneous and the reaction is complete; After this, the gac of 26kg is added in the reaction kettle 2, fu...

Embodiment 2

[0044] Get the sucrose that 260kg carbonization method makes, the sorbitol of 260kg, add appropriate thickening agent according to the viscosity of the colorless liquid that filters from reactor 2, other conditions are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com