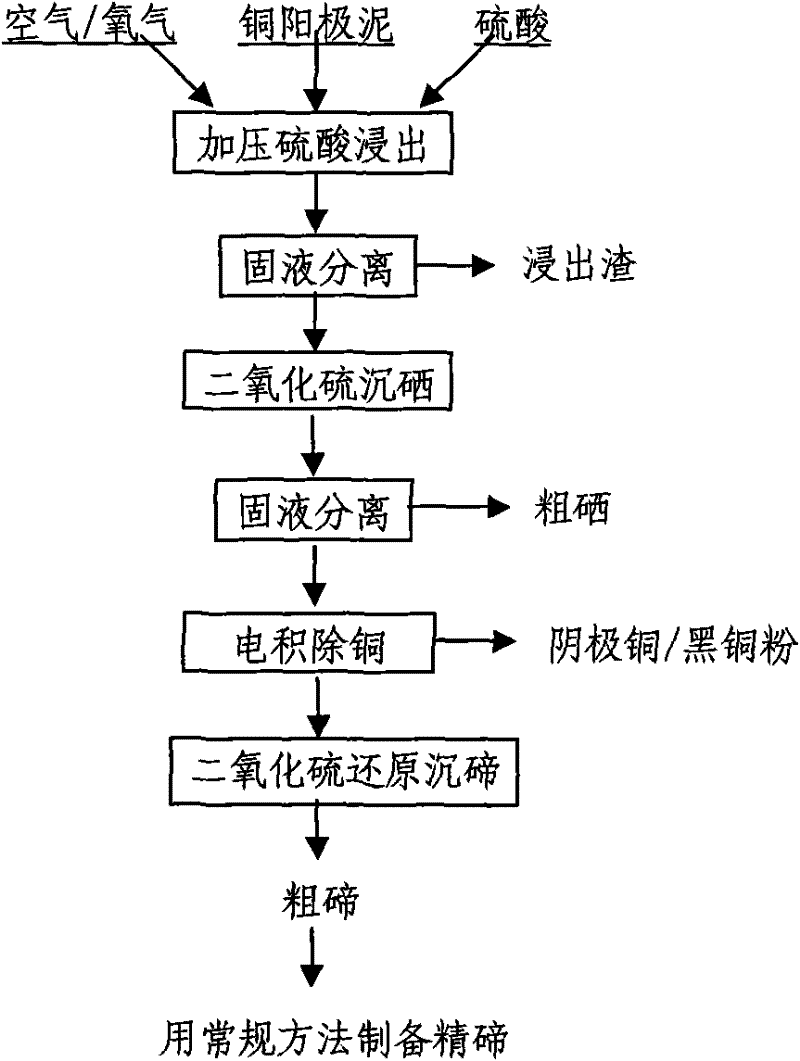

Method for extracting tellurium from copper anode sludge

A copper anode slime and leaching technology, which is applied to the improvement of process efficiency, photography process, instruments, etc., can solve the problems of complex process, increased consumption of chemicals, consumption, etc., to simplify the process flow, reduce production costs, and achieve good separation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add sulfur dioxide to the above-mentioned oxygen pressure acid leaching solution to reduce the selenium precipitation, reduce the selenium precipitation under the conditions of a reduction temperature of 80°C, a reduction time of 4h, and a sulfur dioxide consumption of 5Kg / Kg selenium to obtain crude selenium, and the selenium content of the liquid after selenium removal is 0.01g / kg. l. The selenium-precipitated solution is then electrowinning to remove copper to obtain a copper-removed solution with a copper content of 1g / l, and then add hydrochloric acid to the copper-removed solution, at a chloride ion concentration of 30g / l, a reduction temperature of 75°C, and a reduction time of 1h , Sulfur dioxide consumption is 3Kg / Kg tellurium. Under the condition of tellurium, sulfur dioxide is introduced to precipitate tellurium. After the tellurium is precipitated, the tellurium content in the liquid is 0.01g / l, and the crude tellurium grade is 86%.

Embodiment 2

[0038]Add sulfur dioxide to the above-mentioned oxygen pressure acid leaching solution to reduce the selenium precipitation, reduce the selenium precipitation under the conditions of 90°C reduction temperature, 3h reduction time, and sulfur dioxide consumption of 3Kg / Kg selenium to obtain crude selenium, and the selenium content of the liquid after selenium removal is 0.06g / kg. l. The selenium-precipitated liquid is then electrowinning to remove copper to obtain a copper-removed liquid with a copper content of 2g / l, and then add sodium chloride to the copper-removed liquid with a chloride ion concentration of 10g / l and a reduction temperature of 80°C. The time is 3 hours, and the sulfur dioxide consumption is 6Kg / Kg tellurium. Sulfur dioxide is introduced to precipitate tellurium. After the tellurium precipitation, the tellurium content in the liquid is 0.007g / l, and the crude tellurium grade is 84%.

Embodiment 3

[0040] Add sulfur dioxide to the above-mentioned oxygen pressure acid leaching solution to reduce selenium precipitation, reduce selenium precipitation under the conditions of reduction temperature 90°C, reduction time 0.5h, sulfur dioxide consumption 4Kg / Kg selenium to obtain crude selenium, selenium content after selenium removal 0.1g / l. The selenium-precipitated liquid is then electrowinning to remove copper to obtain a copper-removed liquid with a copper content of 1.5g / l, and then potassium chloride is added to the copper-removed liquid, the chloride ion concentration is 50g / l, and the reduction temperature is 80°C. The reduction time is 0.5h, and the sulfur dioxide consumption is 3Kg / Kg tellurium. Sulfur dioxide is introduced to precipitate tellurium. After the tellurium precipitation, the tellurium content in the solution is 0.02g / l, and the crude tellurium grade is 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com