Preparation method and application of composite microbial feed additive

A technology of feed additives and compound microorganisms, applied in the field of microbial engineering, can solve problems such as inability to store at room temperature for a long time, affect product promotion and application, and poor storage stability, so as to regulate intestinal microecological balance, enhance animal immunity, and promote proliferation and colonization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

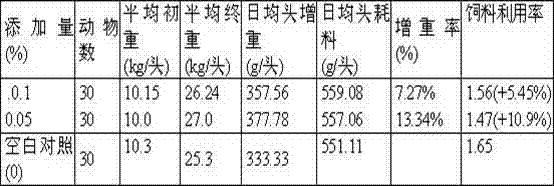

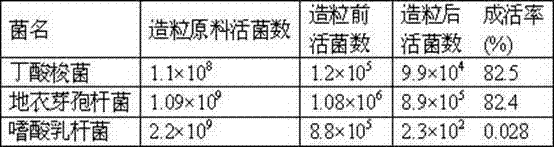

Examples

Embodiment 1

[0067] The preparation method of the compound microbial feed additive, the preparation steps are as follows:

[0068](1) Preparation of Clostridium butyricum live bacteria preparation

[0069] a. Erlenmeyer flask seed culture: Prepare 2200mL of liquid medium according to the formula, adjust the pH to 6.5~7.5, and divide into Erlenmeyer flasks, 100mL in 150mL Erlenmeyer flask, 1900mL in 2000mL Erlenmeyer flask, sterilize at 121°C for 30 minutes, and sterilize for 30 minutes after cooling. CGMCC No.4664 freezing tube was inoculated into a 150mL triangular flask, and cultured at 30~38°C under anaerobic conditions for 14 hours; the grown Clostridium butyricum seeds were transferred into a 2000mL triangular flask with 5% inoculum In the bottle, culture statically at 30~38°C for 24 hours.

[0070] b. Seed tank cultivation: Add liquid culture medium to a 50L seed tank with a liquid volume of 70%, adjust the pH to 7.0~8.5, start stirring, sterilize at 121°C for 30 minutes, turn on co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com