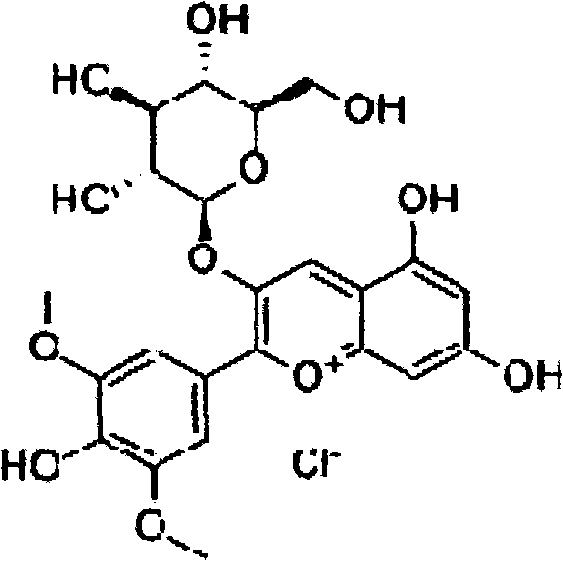

Method for separating and purifying malvidin glucoside from grape-skin red

A technology for malvain and glucoside, which is applied in the field of separation and purification of high-purity malvain glucoside, can solve the problems of large amount of filler, high price and high production cost, and achieves the effects of large separation capacity, low cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) After dissolving 500.0g of grape skin red with 5L of water completely, put it on the D101 macroporous adsorption resin column through treatment, and use the collected eluent to rinse the column repeatedly to make it fully adsorbed, then use pH 3 water and The volume percentage is the gradient elution of 20%, 40%, 60%, 80% and 95% ethanol aqueous solution, and every 1L is used as a receiving volume, detected by HPLC, and the components rich in malvalin glucoside are combined, and the Concentrate under reduced pressure at a temperature of ≤70°C and a vacuum of 0.05-0.08 MPa to obtain 3.1 g of crude product I, with a malvalin glucoside content of 21.8%.

[0027] (2) After mixing 250.0 g of activated carbon and 250.0 g of diatomaceous earth evenly, soak in chloroform for 30 minutes, and wet-pack the column with a diameter-to-height ratio of 1:8. Get the crude product I (the average content of malvalin glucoside is 22.3%) 50.0g obtained by macroporous adsorption resin en...

Embodiment 2

[0032] (1) After dissolving 500.0g of grape skin red with 5L of water completely, put it on the D201 macroporous adsorption resin column after treatment, and use the collected eluent to rinse the column repeatedly to make it fully adsorbed, then use pH 4 water and The volume percentage is 15%, 30%, 45%, 60%, 75% and 95% ethanol aqueous solution gradient elution, each 1L is used as a receiving volume, detected by HPLC, and the components rich in malvalin glucoside are combined, Concentrate it under reduced pressure at a temperature of ≤70°C and a vacuum of 0.05-0.08 MPa to obtain 2.8 g of crude product I, with a malvalin glucoside content of 23.2%.

[0033] (2) After mixing 250.0 g of activated carbon and 250.0 g of diatomaceous earth evenly, soak in chloroform for 30 minutes, and wet-pack the column with a diameter-to-height ratio of 1:4. Get the crude product I (the average content of malvalin glucoside is 24.1%) 50.0g that macroporous adsorption resin enrichment obtains and ...

Embodiment 3

[0038] (1) After completely dissolving 500.0g grape skin red with 5L water, put it on the treated Diaion HP-20 macroporous adsorption resin column, and wash the column repeatedly with the collected eluent to make it fully adsorbed, then use a pH value of 5 Gradient elution of water and 20%, 40%, 60%, 80% and 95% ethanol aqueous solution by volume percentage, each 1L is regarded as a receiving volume, detected by HPLC, and the components rich in malvalin glucoside are combined , concentrated under reduced pressure at a temperature of ≤70° C. and a vacuum of 0.05 to 0.08 MPa to obtain 4.1 g of crude product I, with a malvalin glucoside content of 21.9%.

[0039] (2) After mixing 250.0 g of activated carbon and 250.0 g of diatomaceous earth evenly, soak in chloroform for 30 minutes, and wet-pack the column with a diameter-to-height ratio of 1:8. Get the crude product I (the average content of malvalin glucoside is 26.4%) 50.0g obtained by macroporous adsorption resin enrichment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com