Ironmaking method

A blast furnace and gas furnace technology, applied in the field of iron and steel metallurgy, can solve the problem that the amount of injection cannot be adjusted arbitrarily, and achieve the effect of convenient and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

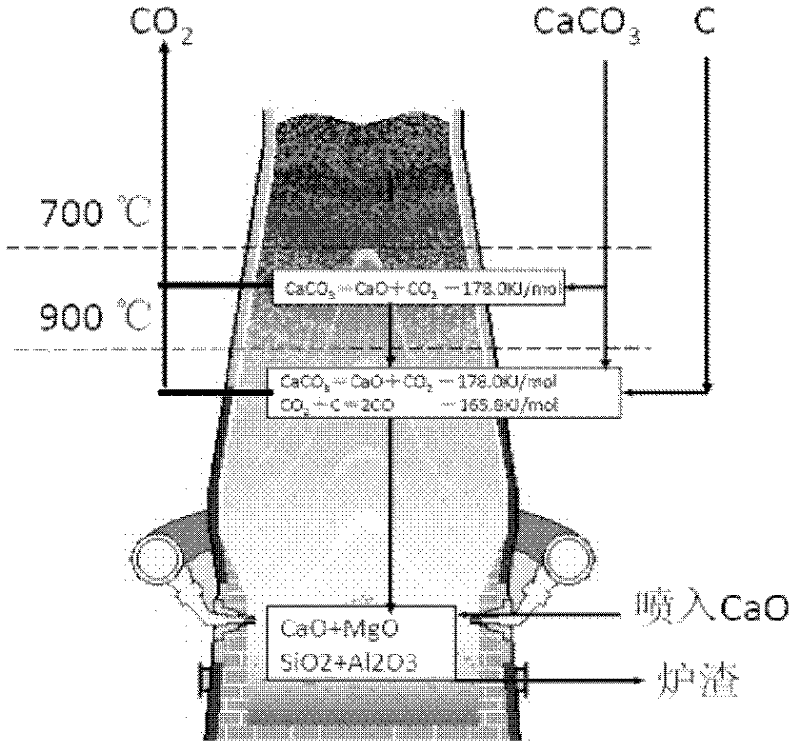

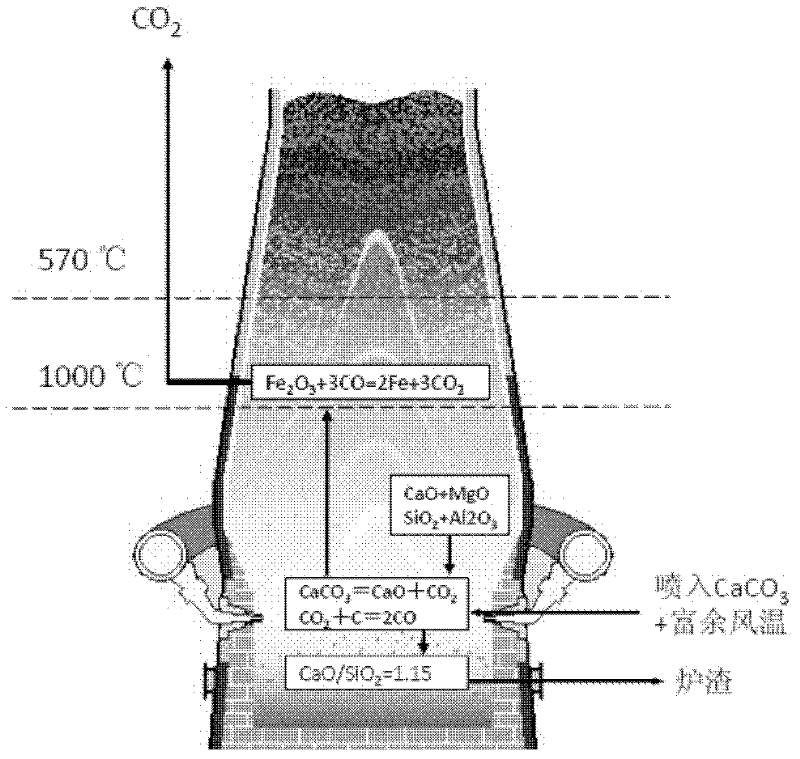

Method used

Image

Examples

Embodiment 1

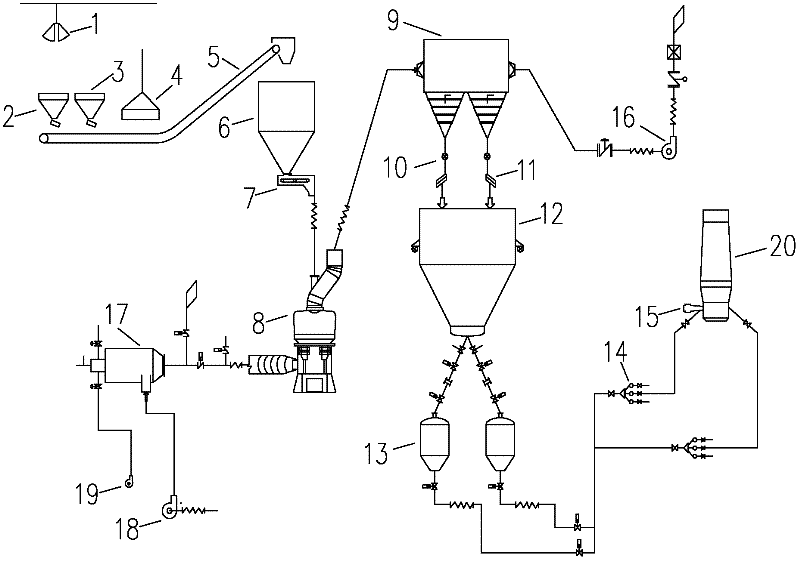

[0077] This embodiment provides a kind of blowing equipment for blowing limestone from tuyeres, its structure is as follows: image 3 As shown, the equipment includes a pulverizing system, a drying flue gas system and an injection system, among which:

[0078] The pulverizing system includes a limestone silo (silo) 6, a vertical mill 8 (with a raw material inlet, a gas inlet and a powder outlet), a bag powder collector 9, and a limestone powder bin 12. The pulverizing system is used to prepare Limestone powder, the pulverizing system also includes a grab crane 1, a batching hopper 2, a feeder 3, an iron remover 4 and a large-inclination belt conveyor 5, which are used to transport limestone raw materials to the limestone bin 6;

[0079] The dry flue gas system includes a flue gas furnace 17, an induced draft fan 18 and a combustion-supporting fan 19, which are used to provide blown gas, and a dry flue gas system commonly used in the art can be used;

[0080] The blowing syste...

Embodiment 2

[0090] The present embodiment provides a kind of blowing equipment that is used for blowing limestone from tuyeres, wherein, the spray gun that adopts is a tuyeres direct blow pipe, and it can comprise a body 23, a limestone powder spray gun 21 and a coal powder spray gun 22, Its structure is as Figure 4 with Figure 5 As shown, among them, Figure 4 for Figure 5 A-A sectional view, Figure 5 for Figure 4 C-C sectional view. It can be seen from the figure that the body 23 is conical, and the tip of the cone extends into the furnace of the blast furnace / gas furnace through the tuyere. The center of the body 23 has a through hole, and the limestone powder spray gun 21 and the coal powder spray gun 22 are arranged on the body. 23, the part near the outside, and the two form an angle of 10-12° with the center line of the through hole, and its end communicates with the above-mentioned through hole for spraying limestone powder into the furnace;

[0091] The other parts of ...

Embodiment 3

[0093] This embodiment provides a method of adding CaCO to the blast furnace through the tuyeres 3 The smelting method includes operations such as feeding, pulverizing, and blowing, wherein, the blowing operation is to inject limestone powder and coal powder from the tuyeres. The smelting method provided in the present embodiment adopts the injection equipment provided in Example 2 to carry out, and the specific steps are as follows:

[0094] Feeding: the limestone raw material is sent into the limestone bin 6 through the grab crane 1, the batching hopper 2, the feeder 3, the iron remover 4 and the large-inclination belt conveyor 5;

[0095] Milling: the limestone raw material is sent to the vertical mill 8 through the closed automatic weighing feeder 7 for crushing and grinding to obtain limestone powder, which is mixed with the gas from the flue gas furnace 17 at the same time, and the limestone powder is crushed by this part of the gas Bring in the bag powder collector 9; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com