Agricultural planting facility with external nutrient source

A nutrient source and agricultural technology, applied in the field of agricultural planting facilities, can solve problems such as energy consumption, inability to achieve temperature control, and low degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

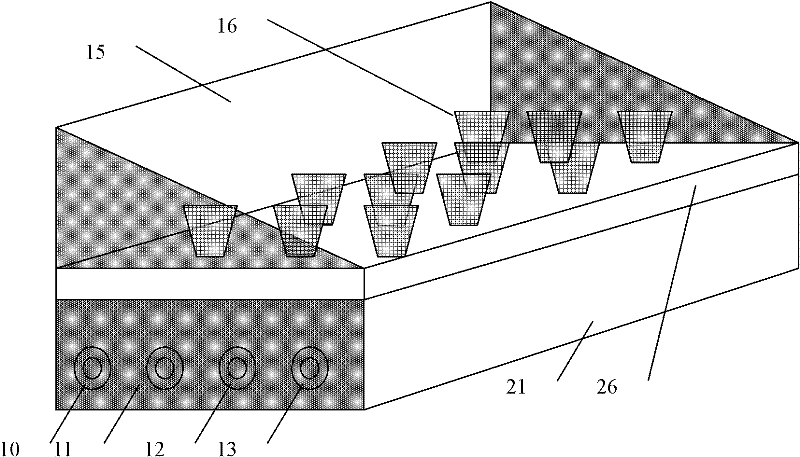

[0038] Example 1: Four-pipe trapezoidal single facility such as figure 1 As shown, this picture is a single agricultural planting facility, which uses four pipelines of liquid pipelines, power pipelines, air-conditioning pipelines, and information pipelines to realize the control of the planting process, and its top is designed as a trapezoidal box covered by vacuum glass. The body is used to realize the lighting of plants, and there is still only a thermal insulation blanket on it, which can insulate the glass that is no longer used for lighting, such as lighting during the day and insulating the glass part at night. Polyurethane insulation materials are used all around to realize the heat preservation of the box. The aerosol cultivation box is set on the trapezoidal box, and various agricultural crops are planted in it. The aerosol cultivation box is set on the partition, and the partition The lower part of the pipe is equipped with four systems of liquid pipes, power pipes,...

Embodiment 2

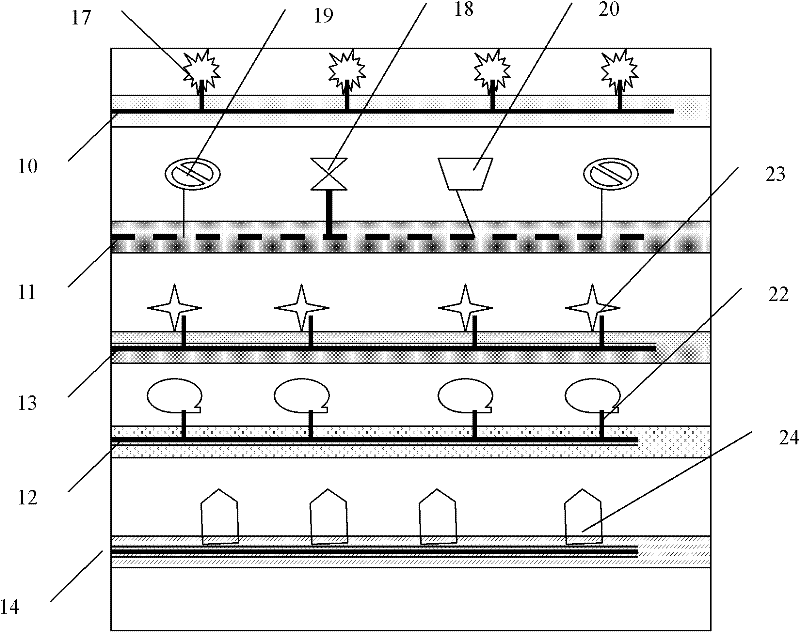

[0039] Embodiment 2: Five pipeline monomer facilities such as figure 2 As shown, five pipelines are arranged inside the box body, nutrient solution pipeline 10, power transmission pipeline 11, air-conditioning heat energy (cold) transmission pipeline 12, information transmission pipeline 13, gas delivery pipeline 14, provide for the planting inside the box body. Required materials, energy, information, nutrient solution pipeline 10, on the nutrient solution delivery pipeline inside the box body, at least one of the following devices is provided to deliver the nutrient solution to the plants inside the box body: A. Aerosol device: Atomize the nutrient solution and deliver it to the roots or leaves of agricultural plants; B. Spraying device: spray the nutrient solution and deliver it to the roots or leaves of the plant; C. Pipe outlet: transfer the nutrient solution fluid delivered to the inside of the box. The power transmission pipeline 11 and the electrical equipment inside...

Embodiment 3

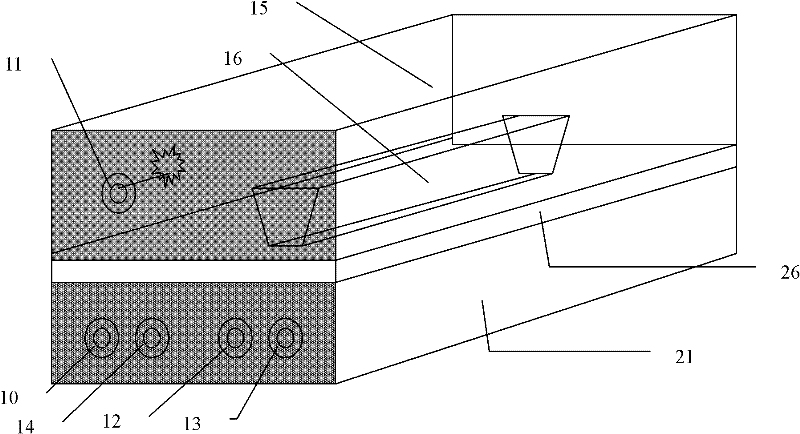

[0040] Embodiment 3: Five-pipe hexahedron monomer facilities such as image 3 As shown, this picture is a single agricultural planting facility in the shape of a hexahedron, using five pipelines for liquid pipelines, power pipelines, air conditioning pipelines, information pipelines, and gas pipelines to realize the control of the planting process. The box covered by vacuum glass is used to realize the lighting of plants. There is still only a thermal insulation blanket on it, which can keep the glass that is no longer used for lighting, such as lighting during the day and insulating the glass part at night. Polyurethane insulation materials are used all around to realize the heat preservation of the box. The aerosol cultivation box is set on the partition, and various agricultural crops are planted in it. The aerosol cultivation box is set on the partition. The lower part of the partition Set up the pipes of four systems: liquid pipes, gas pipes, air-conditioning pipes, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com