Preparation method for catalyst containing MFI structure zeolite

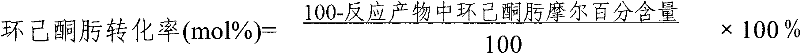

A molecular sieve and catalyst technology, applied in the field of catalyst preparation, can solve the problems of low conversion rate of cyclohexanone oxime, complex fluidized bed process, high requirements on catalyst performance, etc., and achieve high conversion rate, good selectivity and good regeneration performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] This example illustrates the preparation method of the catalyst containing the MFI structure molecular sieve of the present invention.

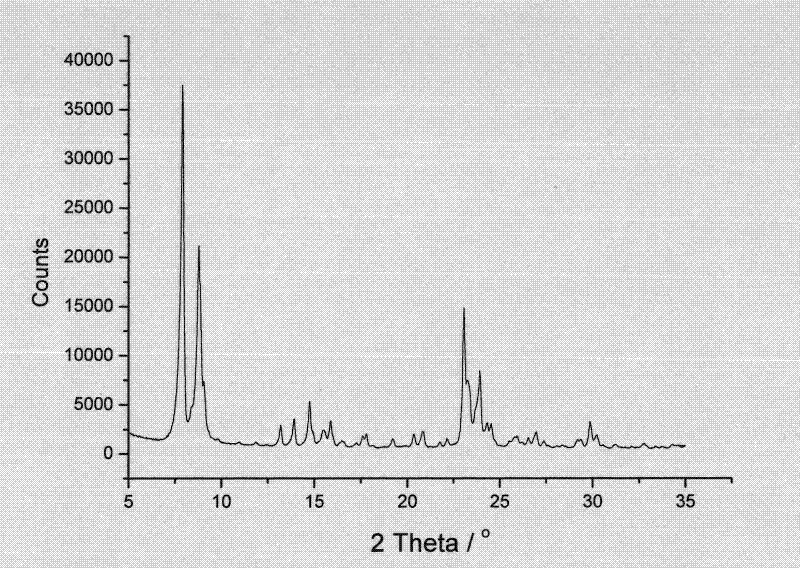

[0028] The preparation process of all-silicon molecular sieve: Pour ethyl orthosilicate (abbreviated as TEOS) into a beaker at room temperature, stir for 30 minutes, add 22.5% tetrapropylammonium hydroxide (abbreviated as TPAOH) solution In ethyl silicate, stir and hydrolyze at room temperature for 3 to 5 hours, add water to form a sol, stir evenly to obtain a molar concentration of TPAOH / SiO 2 =0.22, EtOH / SiO 2 = 4, H 2 O / SiO 2 =18 mixture, transfer the above mixture into a stainless steel reactor lined with polytetrafluoroethylene, crystallize at 100°C for 3 days, filter, wash, dry at 120°C for 24 hours, and calcinate at 550°C for 5 hours to obtain a silicon molecular sieve. The BET specific surface area of the silica molecular sieve product is 439 meters 2 / G, the outer surface is 58 meters 2 / G, the particle size is 0.1~0.2μm, the si...

example 2

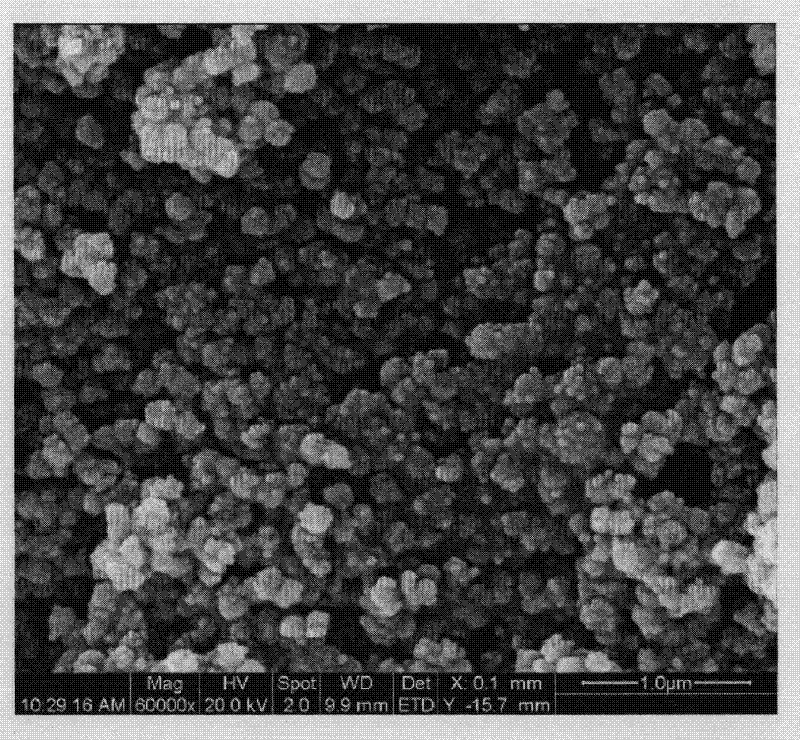

[0042] The preparation process of silicon molecular sieve: Pour ethyl orthosilicate into a beaker at room temperature, stir for 30 minutes, add 22.5% tetrapropylammonium hydroxide solution to ethyl orthosilicate, stir and hydrolyze 3~5 at room temperature After hours, add water to form a sol, stir evenly, and get the molar concentration of TPAOH / SiO 2 =0.15, EtOH / SiO 2 = 4, H 2 O / SiO 2 = 25, transfer the above mixture into a stainless steel reactor lined with polytetrafluoroethylene, crystallize at 100°C for 3 days, filter, wash, dry at 120°C for 24 hours, and calcinate at 550°C for 5 hours to obtain silicon molecular sieve. The BET specific surface area of the silica molecular sieve product is 435 meters 2 / G, the outer surface is 42 meters 2 / G, the particle size is 0.1-0.2μm, and the silicon / aluminum ratio reaches more than 50,000. X-ray diffraction spectrum has figure 1 Features; TEM photos have figure 2 Characteristics.

[0043] 170 grams of silica molecular sieve dry ba...

example 3

[0048] The preparation process of silicon molecular sieve: Pour ethyl orthosilicate into a 1000 ml beaker at room temperature, stir for 30 minutes, add 22.5% tetrapropylammonium hydroxide aqueous solution, stir and hydrolyze at room temperature for 3 hours, add water, stir evenly, and make The chemical composition of the mixed clear liquid is H 2 O / SiO 2 =10, EtOH / SiO 2 =4, TPAOH / SiO 2 =0.18, crystallization at 110°C for 2 days, filtration, washing, drying at 120°C for 24 hours, and baking at 550°C for 5 hours.

[0049] The BET specific surface area of the silica molecular sieve product is 435 meters 2 / G, the outer specific surface is 52 meters 2 / G, the particle size is 0.1-0.2μm, and the silicon / aluminum ratio reaches more than 50,000. X-ray diffraction spectrum has figure 1 Features; TEM photos have figure 2 Characteristics.

[0050] 46.2 grams of silica molecular sieve dry basis, 30 grams of alkaline silica sol (produced by Yueyang, Hunan, SiO 2 The content is 30%, pH=9.0)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crushing strength | aaaaa | aaaaa |

| Crushing strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com