Method for preparing Mg nano particles under carbon source atmosphere

A nanoparticle and carbon source gas technology, applied in the field of metal preparation, can solve the problems of easy aggregation and growth of nanoparticles, less than 20% Mg content, and inability to achieve practical application, etc., achieves important application value, inhibits agglomeration, Defective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1 , Synthetic Mg particles with a particle size of 40nm

[0015] (1) Put the Mg block in a plasma arc heating furnace, evacuated, pass in Ar gas with a pressure of 360 torr and acetylene gas with a pressure of 100 torr, and apply 160A DC arc plasma to obtain Mg nanoparticles.

[0016] (2) Stop heating and evacuate. After the system cools down, air is slowly passed into the furnace for passivation, and the sample is taken out after 48 hours of passivation.

Embodiment 2

[0017] Example 2 , Synthetic Mg particles with a particle size of 40nm

[0018] (1) Put the Mg block in a plasma arc heating furnace, evacuated, pass in Ar gas with a pressure of 360 torr and acetylene gas with a pressure of 60 torr, and apply 200A DC arc plasma to obtain Mg nanoparticles.

[0019] (2) Stop heating and evacuate. After the system cools down, air is slowly passed into the furnace for passivation, and the sample is taken out after 48 hours of passivation.

Embodiment 3

[0020] Example 3 , Synthetic Mg particles with a particle size of 40nm

[0021] (1) Place the Mg block in a plasma arc heating furnace, and after vacuuming, pass in Ar gas with a pressure of 360 torr and acetylene gas with a pressure of 60 torr, and apply 120A DC arc plasma to obtain Mg nanoparticles.

[0022] (2) Stop heating and evacuate. After the system cools down, air is slowly passed into the furnace for passivation, and the sample is taken out after 48 hours of passivation.

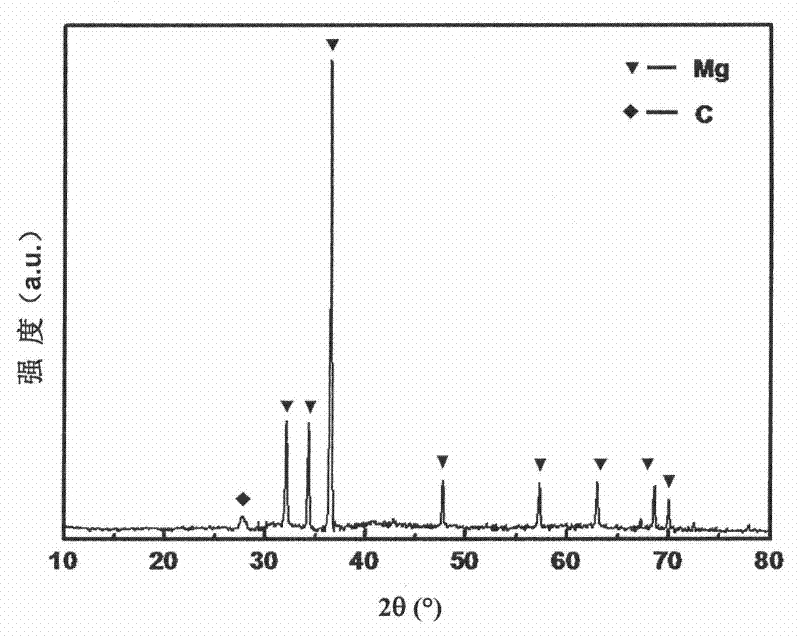

[0023] figure 1 The XRD (X-ray powder diffraction) pattern of the product Mg nanoparticles of the above experiment can clearly see that the purity of the prepared Mg is relatively high.

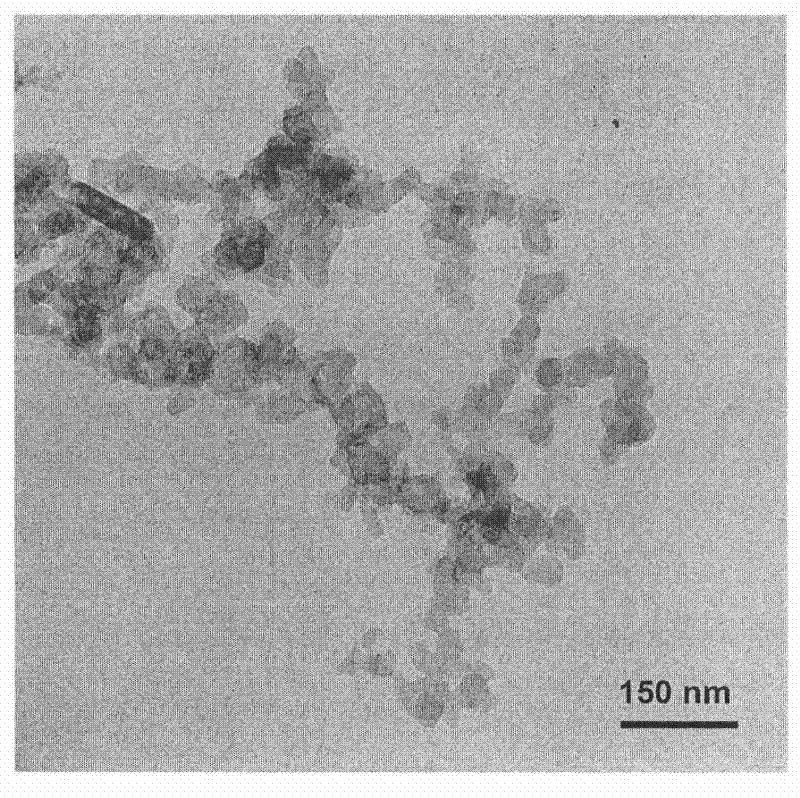

[0024] figure 2 The TEM (transmission electron microscope) image of the above-mentioned experimental product Mg nanoparticles, it can be seen that the size of the Mg nanoparticles is about 40 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com