Pellet binder prepared from residues in direct coal liquefaction process and preparation method thereof

A technology for direct coal liquefaction and binder, applied in the field of circular economy, can solve the problems of high cost and unacceptable steel enterprises, and achieve the effect of reducing the amount of consumption, facilitating promotion and good binding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

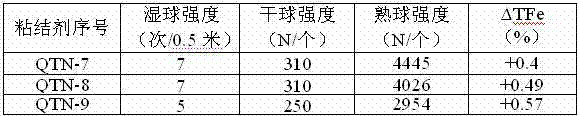

Embodiment 1

[0035] 770 grams of coal liquefaction residue, 200 grams of sodium bentonite, 10 grams of soda ash (sodium carbonate), 20 grams of naphthalene-based dispersant, 300 grams of water, 4 hours after ball milling, the obtained slurry passed through a 300-mesh sieve and became a stable liquid pellet Binder QTN-1.

[0036]

[0037] 850 grams of coal liquefaction residue, 122 grams of sodium bentonite, 8 grams of soda ash (sodium carbonate), 20 grams of naphthalene-based dispersant, 300 grams of water, 4 hours after ball milling, the obtained slurry passed through a 300-mesh sieve and became a stable liquid pellet Binder QTN-2.

[0038]

[0039] 900 grams of coal liquefaction residue, 75 grams of sodium bentonite, 6 grams of soda ash (sodium carbonate), 19 grams of naphthalene-based dispersant, 300 grams of water, 4 hours after ball milling, the obtained slurry passed through a 300-mesh sieve and became a stable liquid pellet Binder QTN-3.

[0040]

[0041] Add the dry powder pel...

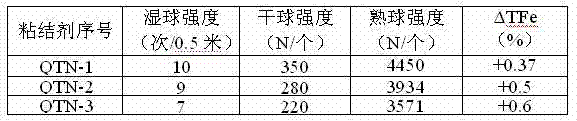

Embodiment 2

[0045] 800 grams of coal liquefaction residue, 170 grams of calcium-based bentonite, 15 grams of soda ash (sodium carbonate), 15 grams of naphthalene-based dispersant, 300 grams of water, after 4 hours of ball milling, the obtained slurry passed through a 300-mesh sieve and became a stable liquid pellet Binder QTN-4.

[0046]

[0047] 850 grams of coal liquefaction residue, 115 grams of calcium-based bentonite, 15 grams of soda ash (sodium carbonate), 20 grams of naphthalene-based dispersant, 300 grams of water, after 4 hours of ball milling, the obtained slurry passed through a 300-mesh sieve and became a stable liquid pellet Binder QTN-5.

[0048]

[0049] 900 grams of coal liquefaction residue, 50 grams of calcium-based bentonite, 30 grams of soda ash (sodium carbonate), 20 grams of naphthalene-based dispersant, 300 grams of water, after 4 hours of ball milling, the obtained slurry passed through a 300-mesh sieve and became a stable liquid pellet Binder QTN-6.

[0050] ...

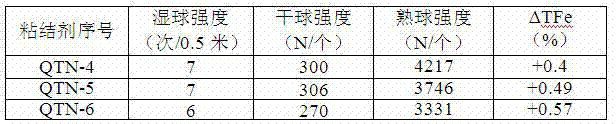

Embodiment 3

[0055] 800 grams of coal liquefaction residue, 160 grams of calcium-based bentonite, 20 grams of soda ash (sodium carbonate), 10 grams of naphthalene-based dispersant, 300 grams of water, 4 hours after ball milling, the obtained slurry passed through a 300-mesh sieve, 150 o Dried at C, crushed into a powder of less than 200 mesh, which is the powder pellet binder QTN-7.

[0056]

[0057] 850 grams of coal liquefaction residue, 100 grams of calcium-based bentonite, 30 grams of soda ash (sodium carbonate), 20 grams of naphthalene-based dispersant, 300 grams of water, 4 hours after ball milling, the obtained slurry passed through a 300-mesh sieve, and dried at 150oC. Crushed into a powder less than 200 mesh, it is the powder pellet binder QTN-8.

[0058]

[0059] 900 grams of coal liquefaction residue, 50 grams of calcium-based bentonite, 30 grams of soda ash (sodium carbonate), 20 grams of naphthalene-based dispersant, 300 grams of water, 4 hours after ball milling, the obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| mana absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com