Method for improving copper dissolving efficiency by using oxygen rich waste acid gas of electrolytic copper foil

An electrolytic copper foil and oxygen-enriched technology, which is applied in the electrolytic process, electrolytic components, electroforming and other directions, can solve the problems of affecting the speed of molten copper, environmental hazards, and reducing the temperature of the molten copper tower, which is beneficial to environmental protection and improves production efficiency. , the effect of speeding up the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

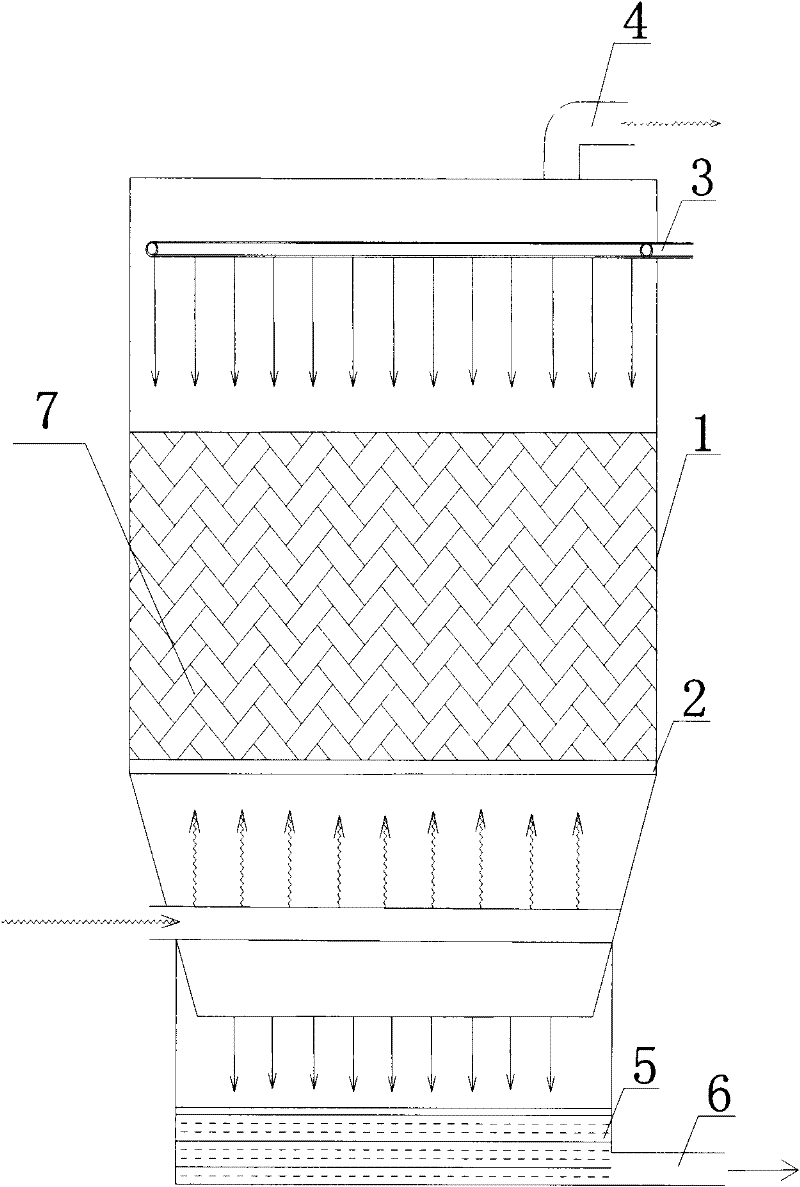

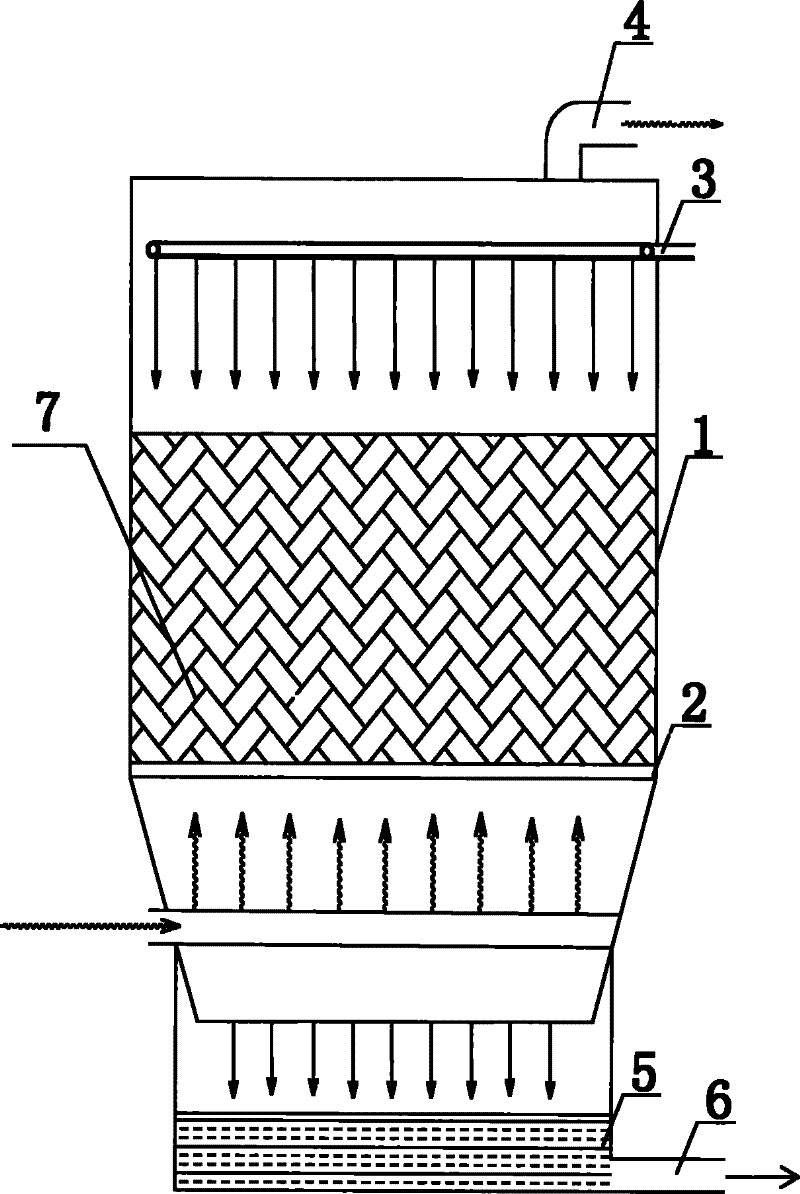

[0018] refer to figure 1 , at room temperature, to a capacity of 88m 3 (The actual effective capacity is 70m 3 ) into the spray-type copper-dissolving tower 1 of 40-50 t of copper wire 7, through the PVC material insulated conveying pipeline, the 30 ℃ oxygen-enriched waste acid collected at 0.1mPa is passed into the copper-dissolving tower 1 from the bottom of the sieve plate 2 Gas, the raw copper wire is in contact with the oxygen in the oxygen-rich waste acid gas, so that the surface of the copper wire is always in an oxidized state, because the oxygen content of the copper melting tower 1 is about 3% higher than the oxygen content directly fed into the air , which is conducive to the generation of copper oxide; the copper sulfate aqueous solution is sprayed on the copper wire 7 through the spray pipe 3 from the top of the copper dissolving tower 1 with a pump, and the copper sulfate aqueous solution and the oxygen-enriched waste acid gas are alternately on the surface of t...

Embodiment 2

[0020] refer to figure 1 , at room temperature, to a capacity of 88m 3 (The actual effective capacity is 70m 3 ) into the spray-type copper-dissolving tower 1 with 40-50t of copper wire 7, through the PVC material insulated delivery pipeline, the 35°C oxygen-enriched waste acid collected at 0.05mPa is passed into the copper-dissolving tower 1 from the bottom of the sieve plate 2 Gas and 0.05mPa air, the raw copper wire is in contact with the oxygen in the oxygen-rich waste acid gas, so that the surface of the copper wire is always in an oxidized state, because the oxygen content of the copper-dissolving tower 1 is higher than the oxygen content of the air directly Increased by about 2%, this is conducive to the generation of copper oxide; the copper sulfate aqueous solution is sprayed on the copper wire 7 through the spray pipe 3 from the top of the copper dissolving tower 1 with a pump, and the copper sulfate aqueous solution and the oxygen-enriched waste acid gas alternatel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com