Method for improving topography and electrical properties of ZnO (zinc oxide) thin film

A technology of electrical properties and thin films, applied in the field of solar cells, can solve problems such as reducing the resistivity of ZnO thin films, and achieve the effects of improving electrical conductivity, improving electrical conductivity, and eliminating edges and corners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

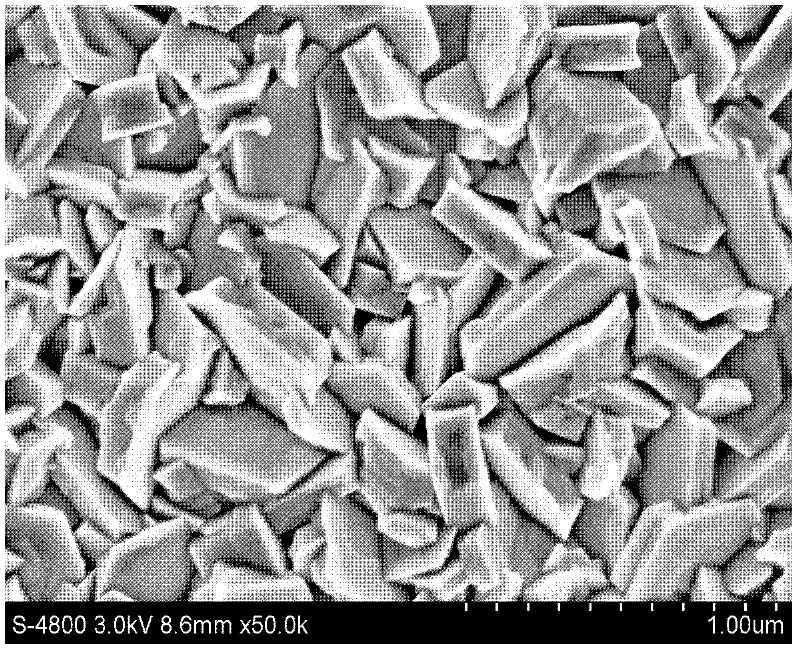

[0032] Using the USP method, zinc acetate is used as Zn source, and indium acetate is used as doped indium source. Water and absolute ethanol were mixed at a ratio of 1:3 as a solvent, and zinc acetate was configured as a 0.2 mol / L solution, and indium acetate was added according to Zn / In=1at.%, and 10vol.% glacial acetic acid was added at the same time. Eagle 2000 glass was used as the substrate. The growth temperature was 470°C. Compressed air was used as the carrier gas, and the surface morphology of the prepared 1at.% In-doped IZO film was as follows figure 1 As shown, its root mean square surface roughness is 62.4nm. More obvious edges and peaks can be seen.

[0033]The AZO film was prepared on the above 1at.% In-doped IZO film by intermediate frequency magnetron sputtering, using a zinc-aluminum alloy target with a mass ratio of 2w.%, at a growth temperature of 280°C, and a reaction gas of high-purity O 2 , the flow rate is 1.5 sccm, and the AZO thin film of 300 nm i...

Embodiment 2

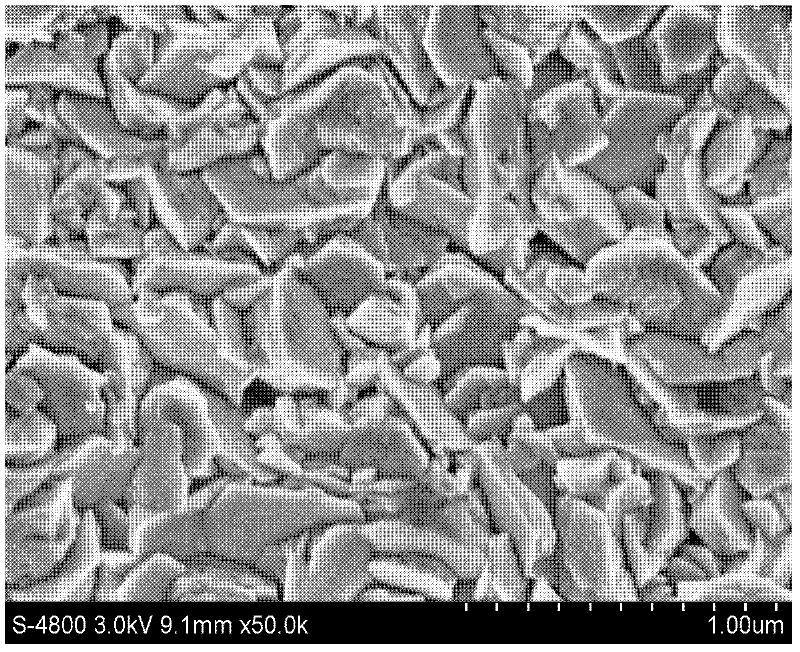

[0035] Using the USP method, zinc acetate is used as Zn source, and indium acetate is used as doped indium source. Water and absolute ethanol were mixed at a ratio of 1:3 as a solvent, and zinc acetate was configured as a 0.2mol / L solution, and indium acetate was added according to Zn / In=1at.%, and 10vol.% glacial acetic acid was added at the same time. Eagle 2000 glass was used as the substrate. The growth temperature was 470°C. Compressed air was used as carrier gas to prepare 1 at.% In-doped IZO film.

[0036] AZO film was prepared on 1at.% In-doped IZO film by intermediate frequency magnetron sputtering method, using a zinc-aluminum alloy target with a mass ratio of 2w.%, at a growth temperature of 280°C, and a reaction gas of high-purity O 2 , the flow rate is 1.5 sccm, and the AZO thin film of 500 nm is prepared by controlling the growth time for 50 min. The surface morphology of the obtained ZnO thin film composite film is as follows: Figure 5 ;and figure 1 For co...

Embodiment 3

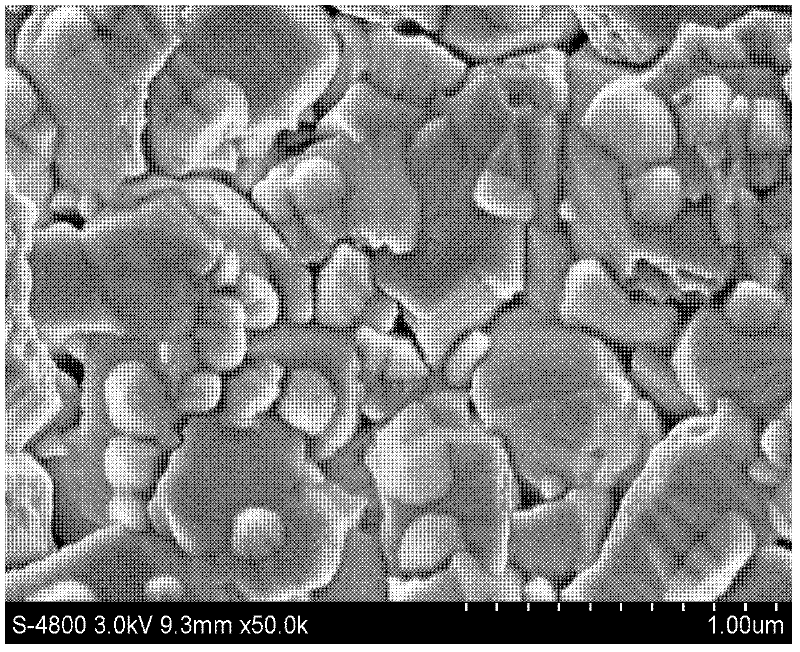

[0038] Using the USP method, zinc acetate is used as Zn source, and indium acetate is used as doped indium source. Water and absolute ethanol were mixed at a ratio of 1:3 as a solvent, and zinc acetate was configured as a 0.2mol / L solution, and indium acetate was added according to Zn / In=1at.%, and 10vol.% glacial acetic acid was added at the same time. Eagle 2000 glass was used as the substrate. The growth temperature was 470°C. Compressed air was used as carrier gas to prepare 1 at.% In-doped IZO film.

[0039] AZO film was prepared on 1at.% In-doped IZO film by intermediate frequency magnetron sputtering method, using a zinc-aluminum alloy target with a mass ratio of 2w.%, at a growth temperature of 280°C, and a reaction gas of high-purity O 2 , the flow rate is 1.5 sccm, and the AZO thin film of 1000 nm is prepared by controlling the growth time for 100 min. The surface morphology of the obtained ZnO thin film composite film is as follows: Figure 7 ;and figure 1 For ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com