Composite porous support material and preparation method thereof

A technology of porous scaffolds and raw materials, applied in the field of materials, can solve the problems of long time and high preparation pressure, and achieve the effects of high porosity, uniform pore size, good adhesion and proliferation state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Taking the preparation of 100g of composite porous scaffold material as an example, the raw materials used and their proportioning ratio are:

[0052] Polylactic acid-polyglycolic acid copolymer 95g

[0053] Hydroxyapatite 2.5g

[0054] Collagen 2.5g

[0055] Its preparation method is as follows:

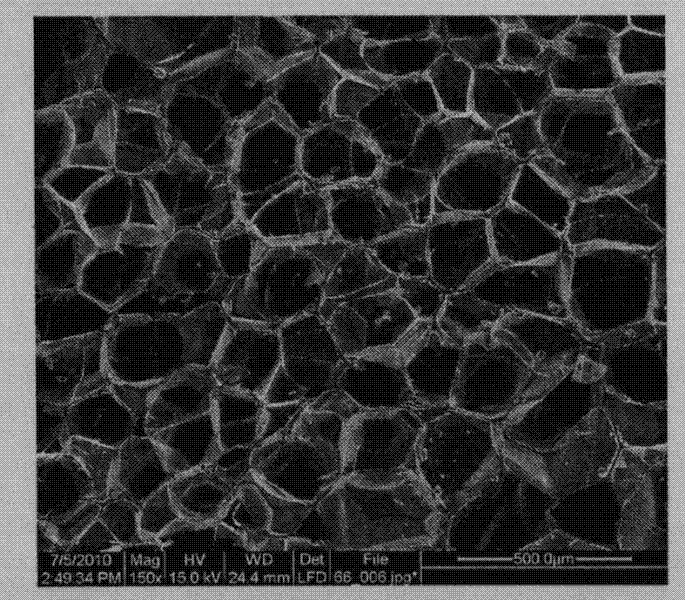

[0056] Take 95g of polylactic acid-polyglycolic acid copolymer, 2.5g of hydroxyapatite, and 2.5g of collagen, mix them evenly, and cold press them into a disc with a diameter of 3cm and a thickness of 1.5cm with a tablet machine. The specific size of the disc is It can be determined according to the size of the reactor within the range of 2-5 cm in diameter and 1-2 cm in thickness. Put the pellets into the mold, and the mold is placed in supercritical CO 2 In the reactor, turn off the CO 2 Vent valve, set reaction pressure to 18MPa, reaction temperature to 45°C, CO 2 Flow rate is 10mL / min, open CO 2 Cylinder valve, high-pressure pump and temperature control valve, make t...

Embodiment 2

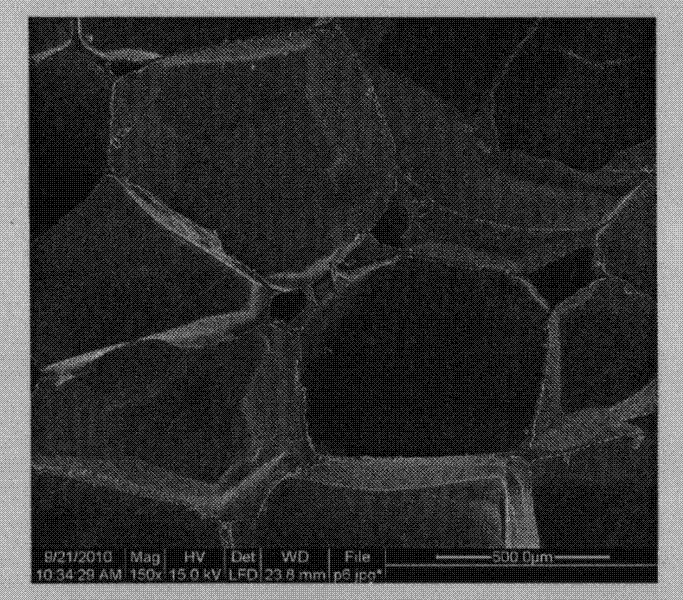

[0059] In Example 1, the mold was placed in supercritical CO 2 In the reactor, turn off the CO 2 Vent valve, set reaction pressure to 12MPa, reaction temperature to 60°C, CO 2 Flow rate is 10mL / min, open CO 2 Cylinder valve, high-pressure pump and temperature control valve, make the pressure and temperature reach the set value, react for 30 minutes, other steps are the same as the corresponding embodiment, and prepare the composite porous scaffold material.

[0060] The morphology of the prepared composite porous scaffold material was characterized by Quanta200 environmental scanning electron microscope, the results are shown in figure 2 , and test its porosity according to the method in Example 1. The results show that some pores of the composite porous scaffold are interconnected, with an average pore diameter of 730 μm and a porosity of 83.6%.

Embodiment 3

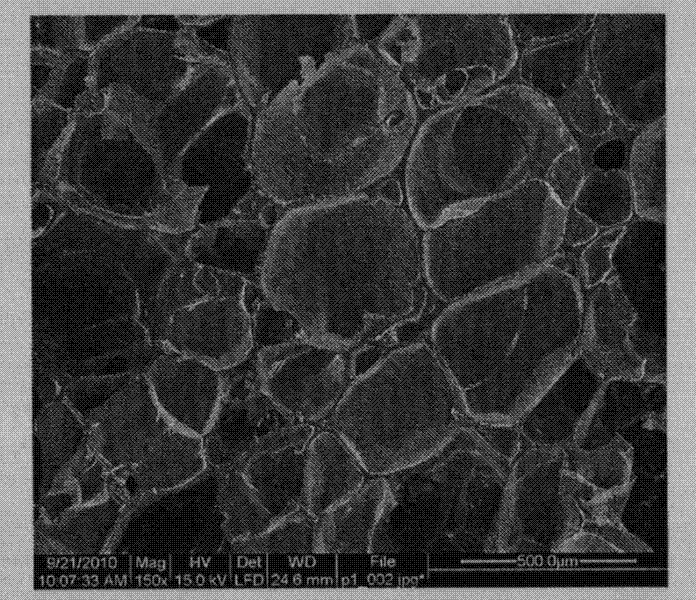

[0062] In Example 1, the mold was placed in supercritical CO 2 In the reactor, turn off the CO 2 Vent valve, set reaction pressure to 12MPa, reaction temperature to 35°C, CO 2 Flow rate is 10mL / min, open CO 2 Cylinder valve, high-pressure pump and temperature control valve, make the pressure and temperature reach the set value, react for 30 minutes, other steps are the same as the corresponding embodiment, and prepare the composite porous scaffold material.

[0063] The morphology of the prepared composite porous scaffold material was characterized by Quanta200 environmental scanning electron microscope, the results are shown in image 3 , and test its porosity according to the method in Example 1. The results show that some pores of the composite porous scaffold are interconnected, with an average pore diameter of 300 μm and a porosity of 48.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com