Organic compound fertilizer produced from kitchen rubbish and preparation method thereof

A compound fertilizer and kitchen waste technology, applied in the direction of organic fertilizer, fertilizer mixture, application, etc., can solve the problems of equipment indigestion, water pollution, etc., and achieve the goal of enhancing water and fertilizer retention capacity, good quality, improving and fertilizing soil Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

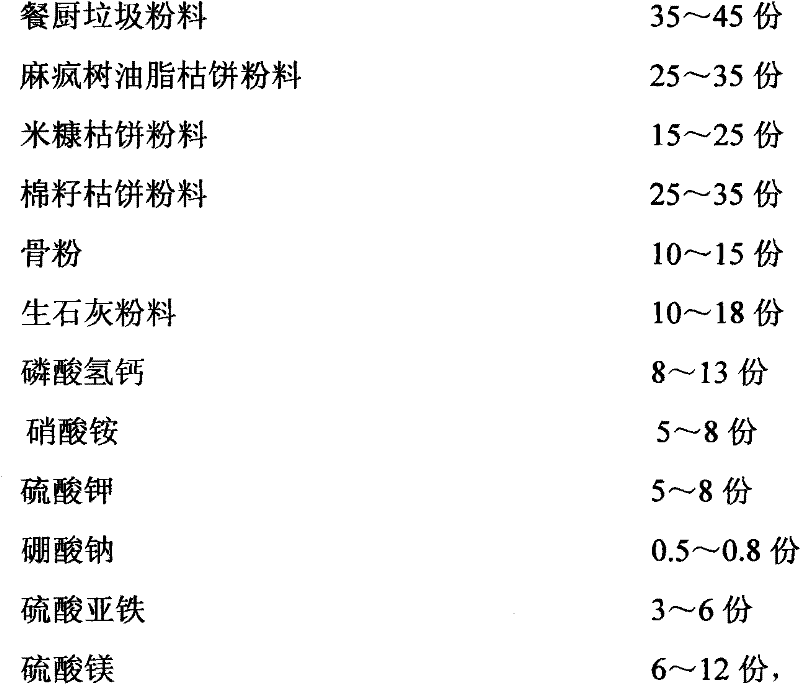

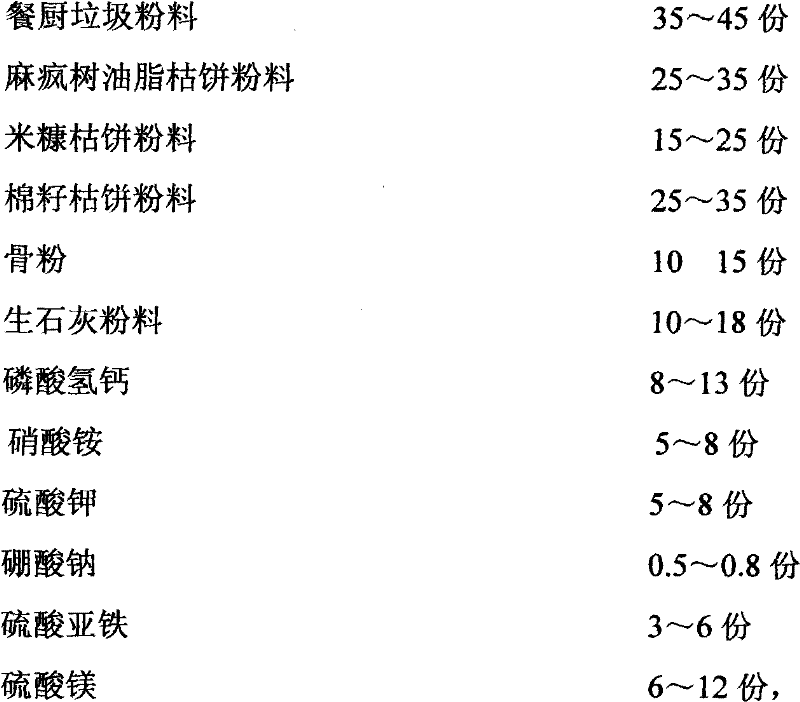

Embodiment 1

[0041] The food residues, slops, and non-edible animal and plant waste edible oils and oil-water mixtures produced in hotels, guesthouses, catering industries, government agencies, schools, and unit canteens are separated and dehydrated by machinery. After high-temperature fermentation, deodorization, disinfection and sterilization, etc., it is digested and processed into decomposed powder, and then dried, milled, and sieved to make food waste powder with a particle size of -0.18mm;

[0042] After the fruit of Jatropha curcas is dried and separated, the grains are crushed, heated, steamed and fried, and the slag cake after the oil is extracted by mechanical processing is fermented at high temperature, dried, milled and sieved to make a particle size of -0.18mm jatropha oil dry cake powder;

[0043] A kind of rice bran separated from rice processing is steam-heated, and the residue cake after extracting oil by mechanical pressing is fermented at high temperature, dried, milled,...

Embodiment 2

[0048] Get the kitchen waste powder material 45kg of embodiment 1, Jatropha curcas grease dry cake powder material 35kg, rice bran dry cake powder material 25kg, cottonseed dry cake powder material 35kg, bone meal 15kg, unslaked lime powder material 18kg, calcium hydrogen phosphate 13kg, nitric acid 8kg of ammonium, 8kg of potassium sulfate, 0.8kg of sodium borate, 6kg of ferrous sulfate and 12kg of magnesium sulfate, the above raw materials are mixed evenly with a biaxial paddle mixer to make a food waste organic compound fertilizer product. After testing, nitrogen content: 2.63%; phosphorus content: 2.04%; potassium content: 0.28%; organic matter content: 46.5%; moisture content: 15.8%; pH: 6.1; all reached Ny525-2002 Chinese People Republic industry standard. For qualified products.

Embodiment 3

[0050] Get the kitchen waste powder material 38kg of embodiment 1, Jatropha curcas grease dry cake powder material 28kg, rice bran dry cake powder material 18kg, cottonseed dry cake powder material 28kg, bone meal 11kg, unslaked lime powder material 12kg, calcium hydrogen phosphate 10kg, nitric acid Ammonium 6kg, Potassium sulfate 6kg, Sodium borate 0.6kg, Ferrous sulfate 4kg and Magnesium sulfate 8kg, the above-mentioned raw materials are mixed uniformly with a twin-shaft paddle mixing mixer to make a food waste organic compound fertilizer product. After testing, nitrogen content: 2.8%; phosphorus content: 2.15%; potassium content: 0.56%; organic matter content: 46.2%; moisture content: 13.5%; pH: 6.5; all reached Ny525-2002 Chinese People Republic industry standard. For qualified products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com