Method for producing laccase by composite fermentation of white-rot fungus

A technology of compound fermentation and white rot fungus, which is applied in the field of bioengineering and microbial fermentation, can solve the problems such as the effect of enzyme production that has not yet appeared, and achieve the effect of high efficiency, stability, good stability and low cost of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

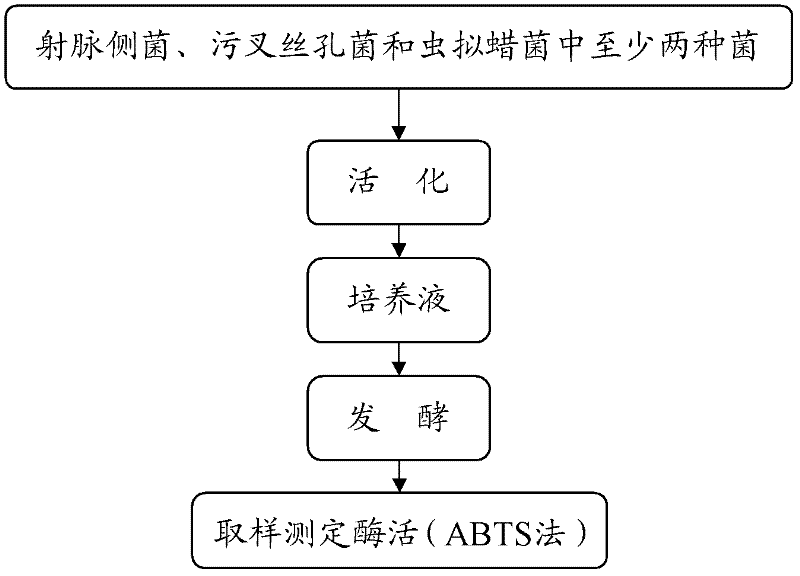

Method used

Image

Examples

Embodiment 1-3

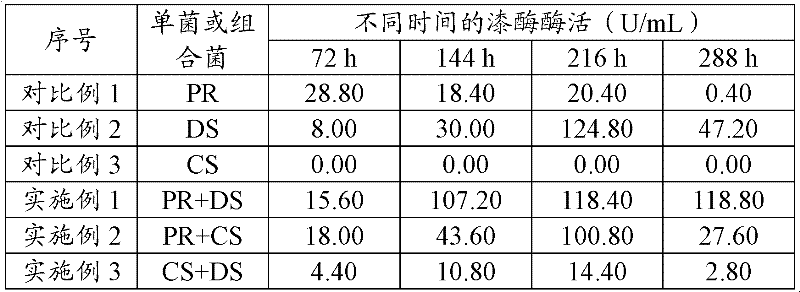

[0021] Example 1-3 Comparison of laccase enzyme activity produced by different combinations of bacteria using corn cob powder raw materials

[0022] (1) Preparation of culture medium: take glucose 1.0g, peptone 0.03g, KH 2 PO 4 0.060g, ZnSO 4 0.0001g, K 2 HPO 4 0.04g, FeSO 4 0.00005g, MnSO 4 0.005g, MgSO 4 0.050g, add 1000mL distilled water, mix well, heat to dissolve, adjust the pH to 6.0, and obtain the basic liquid medium; divide the basic liquid medium into 250mL Erlenmeyer flasks, and the basic liquid medium contained in each Erlenmeyer flask 30 mL, each of which was added 3.0 g of corncob powder crushed to 60 mesh, and stirred evenly to obtain a culture solution.

[0023] (2) Activation of bacterial strains: Inoculate Pleurotus radiatus (PR), Pyriophthora cerevisiae (DS) and Cerexoides cerevisiae (CS) on the potato dextrose agar plate medium of the same thickness that has been sterilized respectively , activated and cultured at 28°C for 7 days.

[0024] (3) Inoc...

Embodiment 4-7

[0031] Example 4-7 Comparing the Enzyme Activity of Laccase Produced by Different Raw Materials by Combination Bacteria Phytophthora radiata and Pyreophthora filatus

[0032] (1) Preparation of culture medium: take glucose 1.0g, peptone 0.03g, KH 2 PO 4 0.060g, ZnSO 4 0.0001g, K 2 HPO 4 0.04g, FeSO 4 0.00005g, MnSO 4 0.005g, MgSO 4 0.050g, add 1000mL distilled water, mix well, heat to dissolve, adjust the pH to 6.0, and obtain the basic liquid medium; divide the basic liquid medium into 250mL Erlenmeyer flasks, and the basic liquid medium contained in each Erlenmeyer flask 30 mL, add 3.0 g of corn stalk powder crushed to 60 mesh, or 3.0 g of corn stalk powder crushed to 60 mesh, or 3.0 g of wheat stalk powder crushed to 60 mesh, or 3.0 g of straw powder crushed to 60 mesh, and stir The culture solution containing different crop stalk powder raw materials can be obtained evenly.

[0033] (2) Activation of the strains: Inoculate Pleurotus radiata (PR) and Pyriophthora fi...

Embodiment 8-9

[0039] Example 8-9 Effects of Different Glucose Concentrations in the Culture Solution on the Laccase Production of the Combination Bacteria of A.

[0040] (1) Preparation of culture medium: take glucose, peptone 0.03g, KH 2 PO 4 0.060g, ZnSO 4 0.0001g, K 2 HPO 4 0.04g, FeSO 4 0.00005g, MnSO 4 0.005g, MgSO 4 0.050g, add 1000mL distilled water, mix well, heat to dissolve, adjust the pH to 6.0, and obtain the basic liquid medium, in which the glucose addition is 0.1g and 1.0g respectively; divide the basic liquid medium into 250mL Erlenmeyer flasks Each Erlenmeyer flask contained 30 mL of basic liquid culture medium, and 3.0 g of corn cob powder crushed to 60 mesh was added to each of them, and stirred evenly to obtain culture liquids containing different concentrations of glucose.

[0041] (2) Activation of the strains: Inoculate Pleurotus radiata (PR) and Pyriophthora filthii (DS) on potato dextrose agar plates of the same thickness that have been sterilized, respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com