Thermally-stable hydroxyapatite whisker and preparation method thereof

A technology of hydroxyapatite and thermal stability, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of inability to strengthen and toughen matrix materials, and achieve easy operation, high thermal stability, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

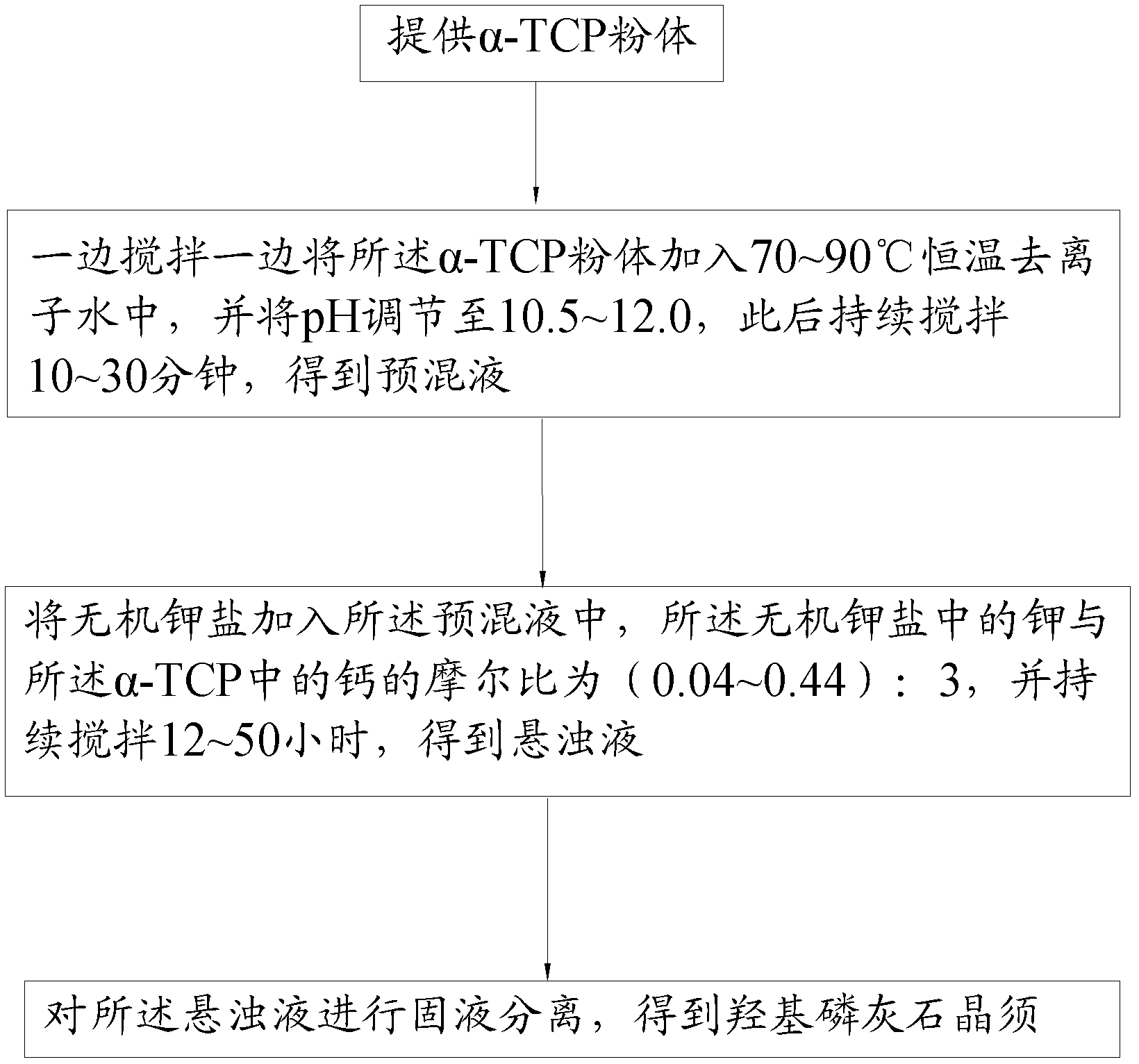

[0034] The preparation method of the thermally stable hydroxyapatite whisker according to the embodiment of the present invention comprises the following steps:

[0035] a) Provide α-TCP powder.

[0036] There is no special requirement for the α-TCP powder, for example, it may be a commercially available α-TCP powder, or α-TCP powder prepared by mixing and calcining may be used.

[0037] In some examples of the present invention, α-TCP powder is prepared through the following steps:

[0038] a-1) Calcium hydrogen phosphate (CaHPO 4 2H 2 O) and calcium carbonate (CaCO 3 ) in a molar ratio of 2:1 in deionized water or absolute ethanol medium for 12 to 48 hours to obtain a slurry.

[0039] The time for ball milling is not particularly limited, as long as it can be fully mixed, but in terms of mixing uniformity and cost, it is preferably ball milled for 12 to 48 hours, more preferably 24 to 48 hours.

[0040] a-2) Drying and pulverizing the slurry to obtain prefabricated powd...

Embodiment 1

[0070] First, measure 400ml of deionized water with a beaker, place it in a water bath at 70°C, and keep stirring.

[0071] Next, weigh 20 g of the α-TCP powder obtained above, slowly pour it into the above beaker, add ammonia water to adjust the pH to 10.5, and stir for half an hour to obtain a premix.

[0072] Thereafter, 0.20 g of KCl was added to the premixed liquid, and the stirring was continued for 24 hours to obtain a suspension.

[0073] After the suspension was precipitated and centrifuged, hydroxyapatite whiskers were obtained.

[0074] Finally, the above-mentioned hydroxyapatite whiskers were washed 3 times with deionized water, and then washed 3 times with alcohol, then suction filtered and dried.

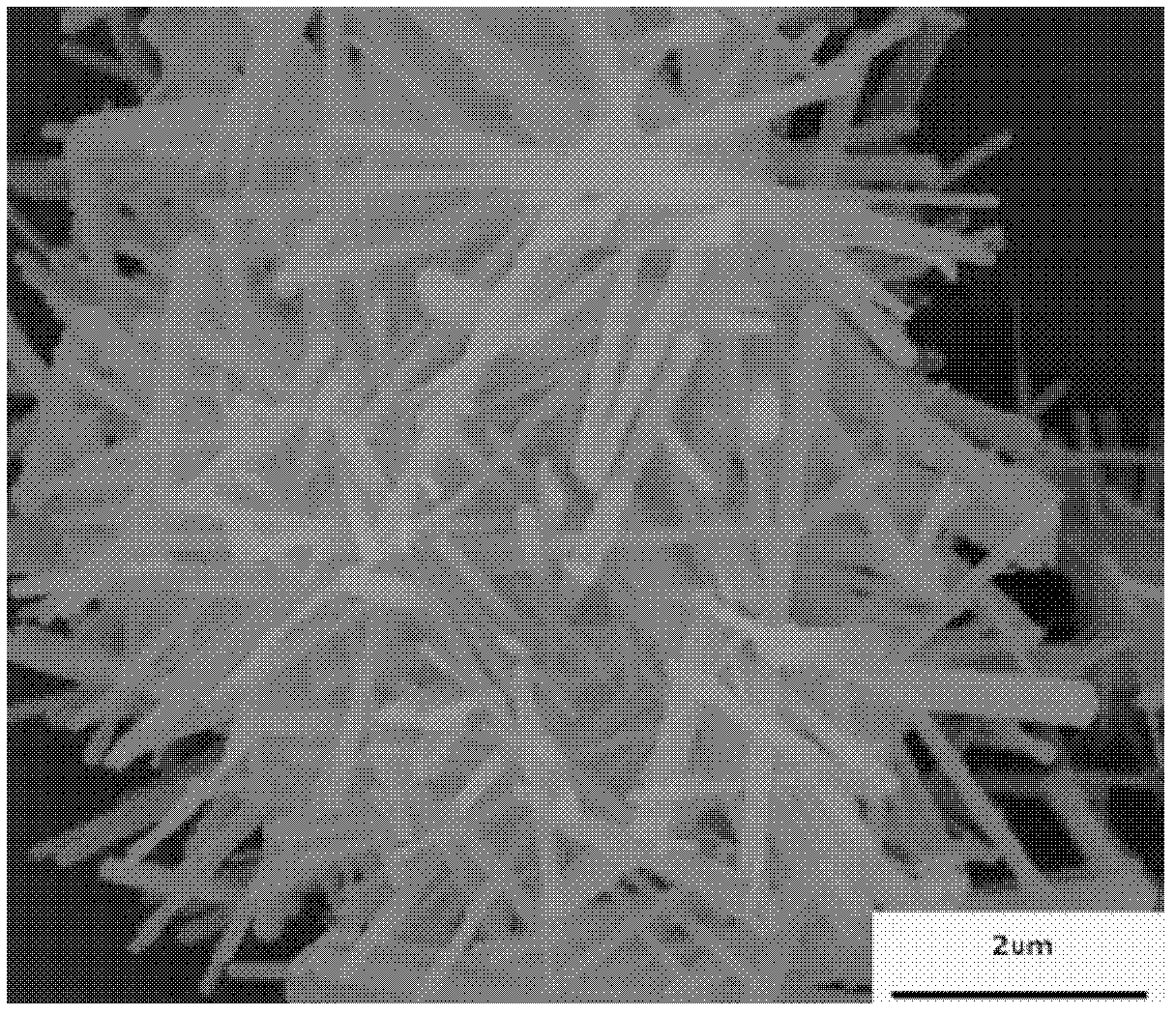

[0075] The morphology of the washed and dried hydroxyapatite whiskers is as follows: figure 2 as shown in a.

[0076] In addition, in order to study the thermal stability of the treated HA whiskers, the HA whiskers were calcined at 1000 °C for 2 hours, and their mo...

Embodiment 2

[0079] First, measure 1000ml of deionized water with a beaker, place it in a water bath at 90°C, and keep stirring.

[0080] Next, weigh 10 g of the α-TCP powder obtained above, slowly pour it into the above beaker, add ammonia water to adjust the pH value to 11.5, and stir for half an hour to obtain a premix.

[0081] Thereafter, 0.82 g of KCl was added to the premixed liquid, and stirring was continued for 24 hours to obtain a suspension.

[0082] After the suspension was precipitated and centrifuged, hydroxyapatite whiskers were obtained.

[0083] Finally, the above-mentioned hydroxyapatite whiskers were washed 3 times with deionized water, and then washed 3 times with alcohol, then suction filtered and dried.

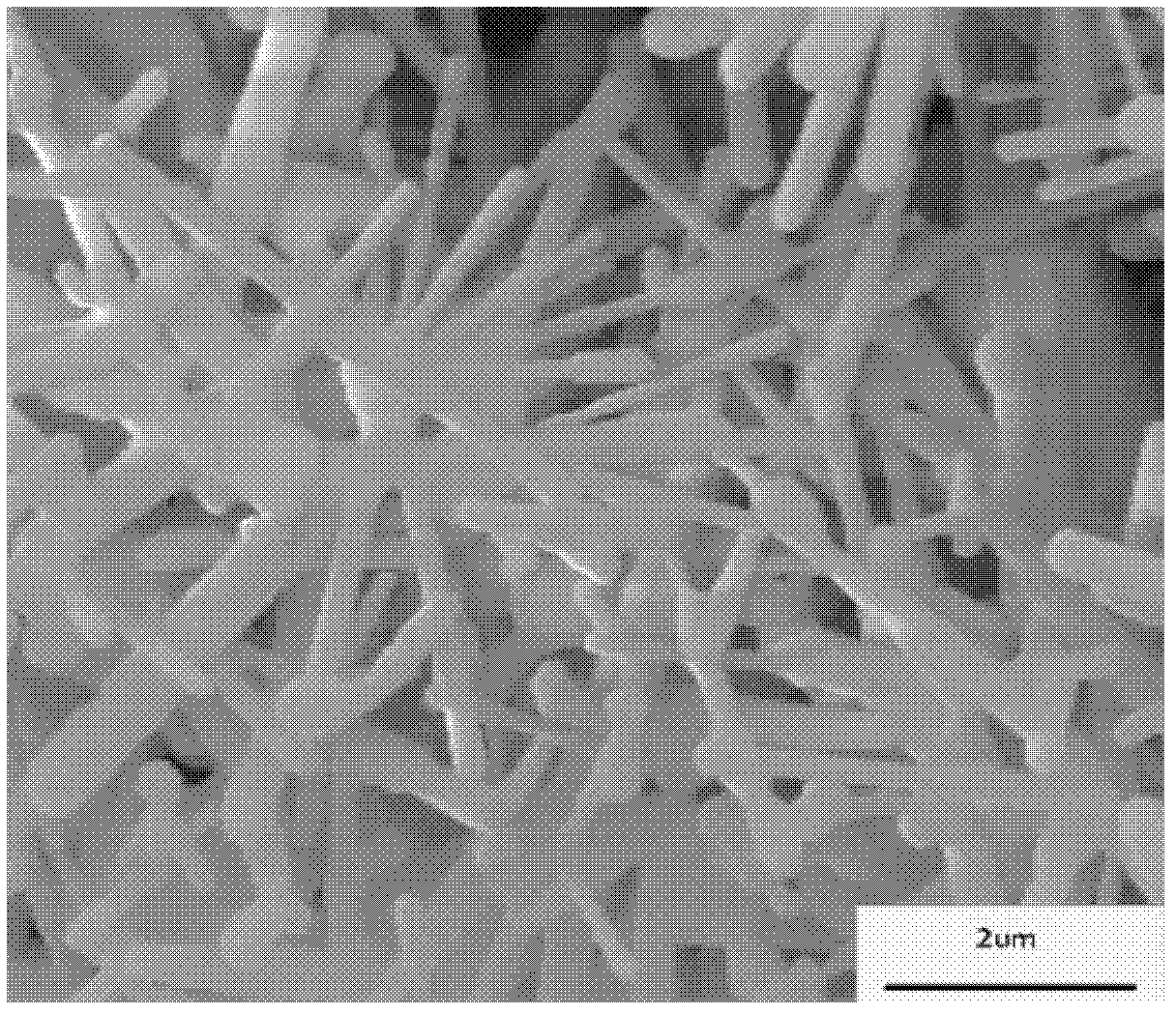

[0084] The morphology of the cleaned and dried hydroxyapatite whiskers and the morphology after calcination at 1000 °C for 2 hours were compared with those of figure 2 with image 3 similar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com