Titanium dioxide light anode, and preparation method and use thereof

A technology of titanium dioxide and photoanode, which is applied in the field of photoanode to achieve the effects of novel appearance, simple preparation and increased scattering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

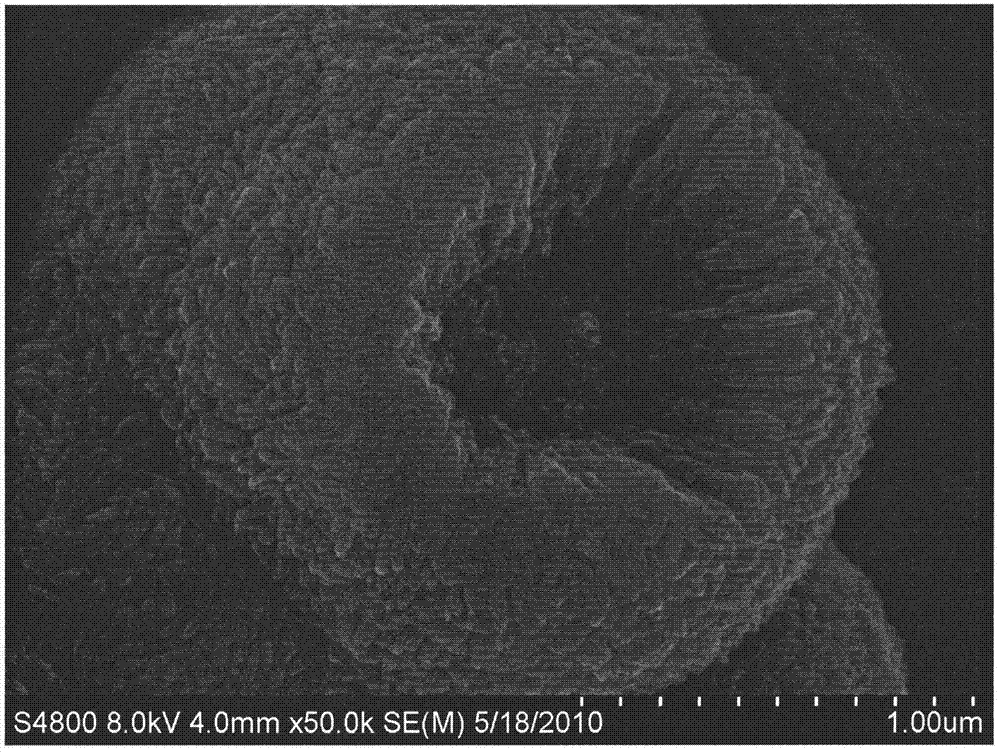

[0033] Example 1: The photoelectric conversion performance of 0.2g of 1000nm annular titanium dioxide microspheres and 5ml of absolute ethanol uniformly mixed and coated on a titanium dioxide film electrode.

[0034] 1000nm (microsphere diameter) annular titanium dioxide microspheres (see figure 2 (shown) is obtained from 0.51ml tetrabutyl titanate, 0.2ml hydrofluoric acid, 16h, solvothermal at 180°C. Rotate and centrifuge, dry in an oven at 60°C for 3 hours, then mix 0.2g of high-power ultrasound with 5ml of absolute ethanol, and then stir for 1 hour to coat a film on the photoanode of titanium dioxide nanoparticles, with a film thickness of about 12μm. The conductive glass coated with the film was calcined in a muffle furnace at 450° C. for 2 hours to obtain a double-layer structure photoanode of the dye-sensitized nanocrystalline solar cell. The photoanode was soaked in a concentration of 5×10 -4 mol / L ruthenium complex N719 dye (English name: RuL2(NCS)2:2TBA(L=2,2'-bipy...

Embodiment 2

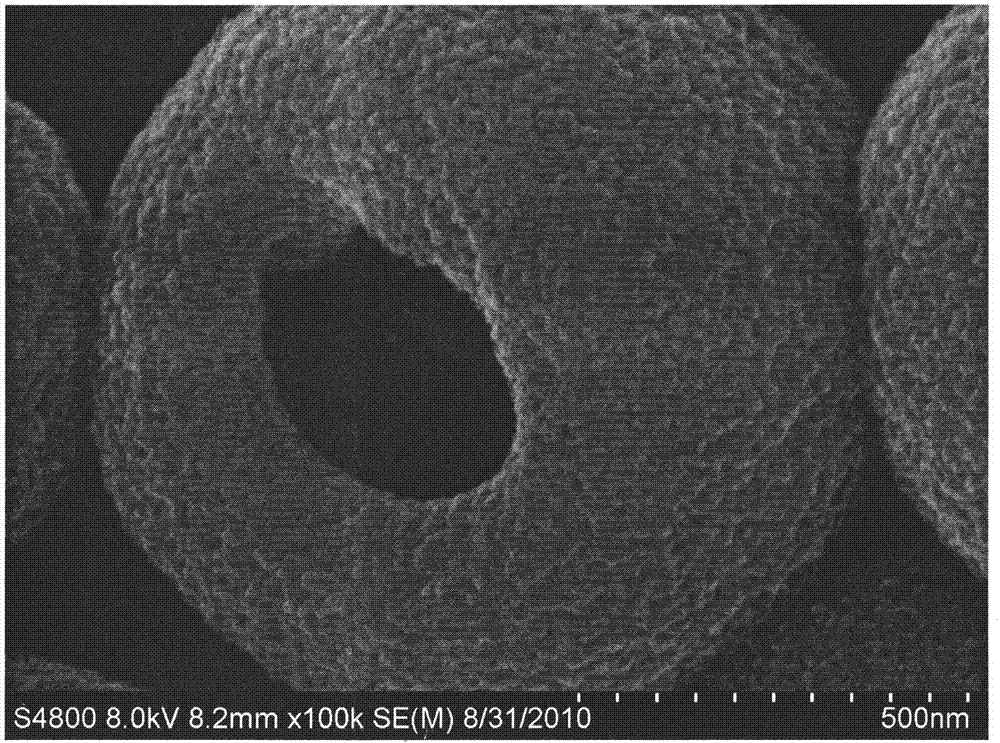

[0035] Embodiment 2: by 0.2g 2000nm spherical titanium dioxide microsphere (see image 3 Shown) and 5ml of absolute ethanol are evenly mixed and coated on the photoelectric conversion performance of the titanium dioxide film electrode.

[0036] 2000nm (microsphere diameter) spherical titanium dioxide microspheres were obtained from 1.02ml tetrabutyl titanate, 16h, solvothermal at 180°C. Rotate and separate, dry in an oven at 60°C for 3h, then mix 0.2g of high-power ultrasound with 5ml of absolute ethanol, and then stir for 1h to coat a film on the photoanode of titanium dioxide nanoparticles, with a film thickness of about 12μm. The conductive glass coated with the film was calcined in a muffle furnace at 450° C. for 2 hours to obtain a double-layer structure photoanode of the dye-sensitized nanocrystalline solar cell. The photoanode was soaked in a concentration of 5×10 -4 mol / L N719 solution for 24 hours, the photoanode was fully sensitized by the dye. Then the photoanode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com