Preparation method of phthalocyanine cobalt sulfonamide desulfurization catalyst

A technology of cobalt phthalocyanine sulfonamide and desulfurization catalyst, which is applied in the field of preparation of new desulfurization catalyst-cobalt phthalocyanine sulfonamide, can solve the problems of phthalic anhydride affecting the yield and product quality, and achieve long catalytic cycle, high-efficiency desulfurization activity, The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

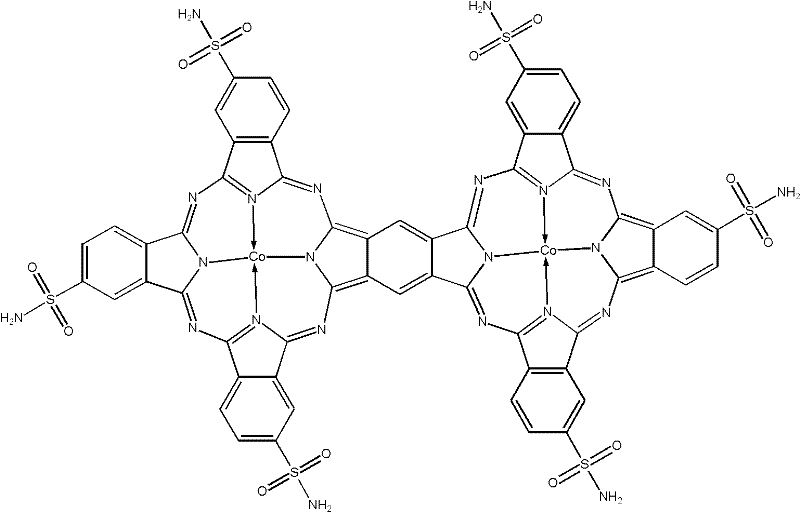

Image

Examples

Embodiment 1

[0021] Take 300g of phthalic anhydride and 600g of chlorosulfonic acid, reflux and sulfonate at 180°C for 8 hours, recover excess chlorosulfonic acid under reduced pressure, add the residue to 1000g of ice water, and filter to obtain the intermediate product, phthalic anhydride sulfonate Acid chloride, yield 67.5%. The recovered chlorosulfonic acid can be used mechanically again.

[0022] Then take 246g of phthalic anhydride sulfonyl chloride, 36g of pyromellitic anhydride, 300g of urea, 43.3g of anhydrous cobalt chloride, 6.5g of ammonium molybdate, and undergo condensation reaction at 190-220°C for 4 hours to generate cobalt phthalocyanine Sulfonamide, the product is dark blue solid.

Embodiment 2

[0024] Take 300g of phthalic anhydride and 400g of chlorosulfonic acid, reflux and sulfonate them at 180°C to 200°C for 8 hours, then add 300g of thionyl chloride and continue reflux for 3 hours, and recover excess thionyl chloride and chlorine under reduced pressure. Sulfonic acid, the residue was added to 1000g ice water, and the intermediate product phthalic anhydride sulfonyl chloride was obtained by filtration. Yield 87.6%. The recovered thionyl chloride and chlorosulfonic acid can be used again after simple fractionation and separation.

[0025] Take 246g of the intermediate product phthalic anhydride sulfonyl chloride, 36g of pyromellitic anhydride, 300g of urea, 43.3g of anhydrous cobalt chloride, 6.5g of ammonium molybdate, and undergo condensation reaction at 190-220°C for 4 hours to generate cobalt phthalocyanine sulfonate Amide, the product is dark blue solid.

Embodiment 3

[0027] Take 300g of phthalic anhydride, recover 600g of chlorosulfonic acid, reflux and sulfonate at 180°C for 8 hours, recover excess chlorosulfonic acid under reduced pressure, add the residue to 1000g of ice water, and filter to obtain the intermediate product of phthalic anhydride Sulfonyl chloride, yield 58.3%. The recovered chlorosulfonic acid can be used mechanically again.

[0028] Then take 246g of phthalic anhydride sulfonyl chloride, 36g of pyromellitic anhydride, 300g of urea, 43.3g of anhydrous cobalt chloride, 6.5g of ammonium molybdate, and undergo condensation reaction at 190-220°C for 4 hours to generate cobalt phthalocyanine Sulfonamide, the product is dark blue solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com