The synthetic method of n-ethylethylenediamine

A technology of ethylethylenediamine and a synthesis method, which is applied in the preparation of amino-substituted functional groups, organic chemistry, etc., can solve problems such as harsh reaction conditions, and achieve the effects of reducing the burden of post-processing, simple process, and good product selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

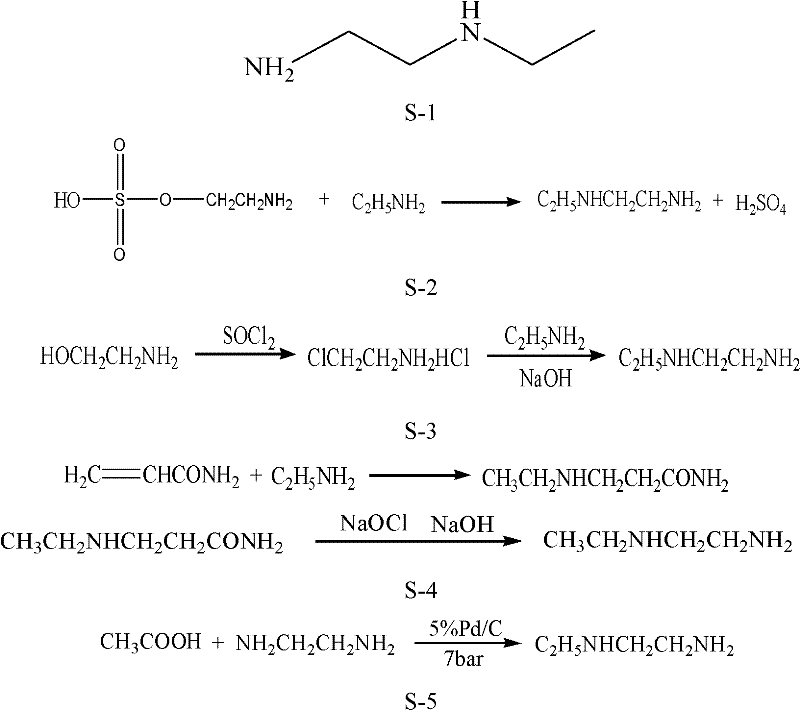

Problems solved by technology

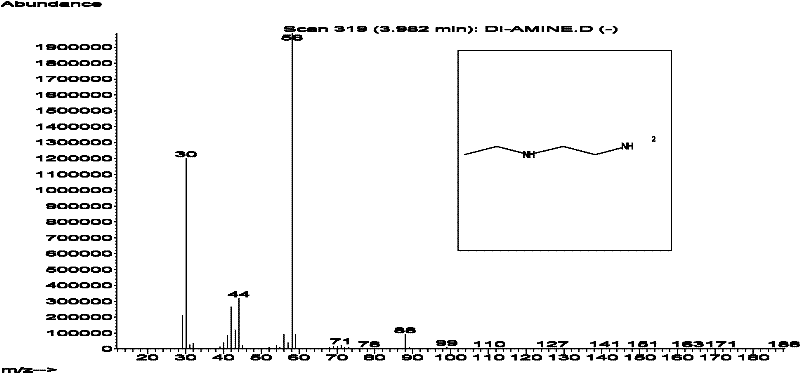

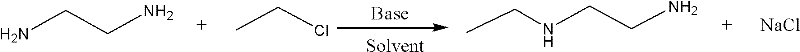

Method used

Image

Examples

Embodiment 1

[0025] The synthetic method of embodiment 1, N-ethylethylenediamine:

[0026] Add 110g (1.6mol) of ethylenediamine, 550g of methanol, and 60g (1.12mol) of sodium methoxide into a high-pressure reactor with a stirring temperature measuring device, and press 52g (0.8mol) of ethyl chloride after closing the lid; The internal temperature is raised to 40°C, and the pressure is 0.5Mpa at this time. Keep the temperature for 6 hours to complete the reaction, and the pressure after the reaction is 0.3Mpa.

[0027] After the reaction, the sodium chloride in the reaction liquid was filtered off, the filtrate was rectified, and the fraction at 128-130°C was collected to obtain 49.3 g of the product N-ethylethylenediamine with a yield of 69.89%.

[0028] The fraction collected at 62-64°C is methanol with a recovery rate of 84.26%; the fraction collected at 114-118°C is ethylenediamine with a recovery rate of 58.25%, both of which can be recycled.

Embodiment 2

[0029] The synthetic method of embodiment 2, N-ethylethylenediamine:

[0030] Add 110g (1.6mol) of ethylenediamine, 220g of methanol, and 47.5g (0.88mol) of sodium methylate into a high-pressure reactor with a stirring temperature measuring device. After closing the lid, press 52g (0.8mol) of ethyl chloride. The temperature was raised to 60°C within 1h, and the pressure was 0.7Mpa at this time. Keep the temperature for 3 hours to complete the reaction, and the pressure after the reaction is 0.36Mpa.

[0031] After the reaction, the sodium chloride in the reaction solution was filtered off, the filtrate was rectified, and the fraction at 128-130°C was collected to obtain 43.2 g of the product N-ethylethylenediamine with a yield of 61.25%.

[0032] At the same time, solvent methanol and excess ethylenediamine were collected, and the recoveries of the two were 84.54% and 58.12% respectively.

Embodiment 3

[0033] The synthetic method of embodiment 3, N-ethylethylenediamine:

[0034] Add 110g (1.6mol) of ethylenediamine, 550g of methanol, and 52g (0.96mol) of sodium methoxide into a high-pressure reaction kettle with a stirring temperature measuring device. After closing the lid of the kettle, press 52g (0.8mol) of ethyl chloride. The internal temperature was raised to 80°C, and the pressure was 1.2Mpa at this time. Keep the temperature for 4 hours to complete the reaction, and the pressure after the reaction is 0.5Mpa.

[0035] After the reaction, the sodium chloride in the reaction solution was filtered off, the filtrate was rectified, and the fraction at 128-130°C was collected to obtain 42.9 g of N-ethylethylenediamine, with a yield of 60.82%.

[0036] At the same time, solvent methanol and excess ethylenediamine were collected, and the recoveries of the two were 86.65% and 59.02% respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com