Premixed fluororubber gum with improved thermal tear resistance and preparation method thereof

A technology of tearing performance and fluororubber raw rubber, which is applied in the field of fluororubber premixed rubber and its preparation, can solve the problems of poor thermal tear resistance and dispersion performance, achieve good thermal tear resistance, improve dispersibility, Good high dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

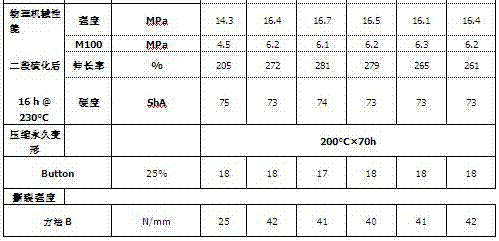

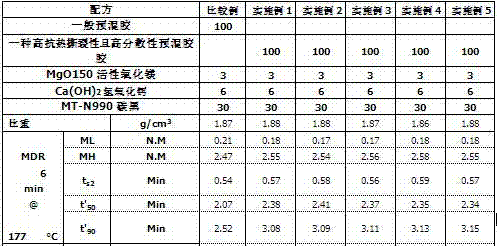

Examples

Embodiment 1

[0037] A modified fluorine rubber premix, consisting of the following parts by weight:

[0038] 80 parts of L2 masterbatch, 1 part of barium sulfate, 0.1 part of PFPE derivative, 0.1 part of fatty alcohol, 5 parts of modified white carbon black masterbatch;

[0039] The L2 masterbatch is prepared by bisphenol AF: vulcanization accelerator BPP: fluorine rubber raw rubber in a mass ratio of 1:0.5:50, wherein the fluorine rubber raw rubber is fluorine rubber 26 and the Mooney viscosity is 15;

[0040] The preparation process of the L2 masterbatch is as follows:

[0041] A. First melt the bisphenol AF and vulcanization accelerator BPP in the above ratio in a stainless steel melting tank at a melting temperature of 150°C and a time of 4 hours. After melting, the material is discharged and placed in a stainless steel receiving tray, at room temperature. Naturally cool to obtain solid block raw materials;

[0042] B. The solid material obtained in step A is pulverized with a high-efficiency p...

Embodiment 2

[0049] A modified fluorine rubber premix, which is composed of the following parts by weight:

[0050] 60 parts of L2 masterbatch, 5 parts of barium sulfate, PFPE derivatives, 1.5 parts, 1.5 parts of fatty alcohol, 10 parts of modified white carbon black masterbatch;

[0051] The L2 masterbatch is prepared by bisphenol AF: vulcanization accelerator BPP: fluorine rubber raw rubber in a mass ratio of 2:0.6:50, wherein the fluorine rubber raw rubber is fluorine rubber 246, and the Mooney viscosity is 30;

[0052] The preparation process of the L2 masterbatch is:

[0053] A. First melt the above-mentioned parts by weight of bisphenol AF and vulcanization accelerator BPP in a stainless steel melting tank. The melting temperature is 180°C and the melting time is 5 hours. After melting, the material is discharged and placed in a stainless steel receiving tray at room temperature. Naturally cool under conditions to obtain solid block materials;

[0054] B. The solid material obtained in step A...

Embodiment 3

[0061] A modified fluorine rubber premix, which is composed of the following parts by weight:

[0062] 80 parts of L2 masterbatch, 3 parts of barium sulfate, 1 part of PFPE derivative, 1 part of fatty alcohol, 15 parts of modified white carbon black masterbatch;

[0063] The L2 masterbatch is prepared from bisphenol AF: vulcanization accelerator BPP: fluorine rubber raw rubber in a mass ratio of 2:1:50, wherein the fluorine rubber raw rubber is fluorine rubber 246, and the Mooney viscosity is 20 fluorine rubber 246 is 85 parts, and fluororubber 246 with a Mooney viscosity of 15 is 15 parts;

[0064] The preparation process of the L2 masterbatch is:

[0065] A. First, bisphenol AF and vulcanization accelerator BPP are melted in a stainless steel melting tank according to the above ratio. The melting temperature is 220 ℃, and the melting time is 5 hours. After melting, the material is discharged and placed in the stainless steel receiving tray at room temperature. Cool down naturally t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com