A self-cleaning solar energy high reflectivity nano film and its manufacturing method

A high-reflectivity, nano-film technology, applied in the field of reflecting sunlight, can solve the problems of shortened service life, high cost, and poor effect, and achieve the effects of long outdoor service life, saving maintenance costs, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

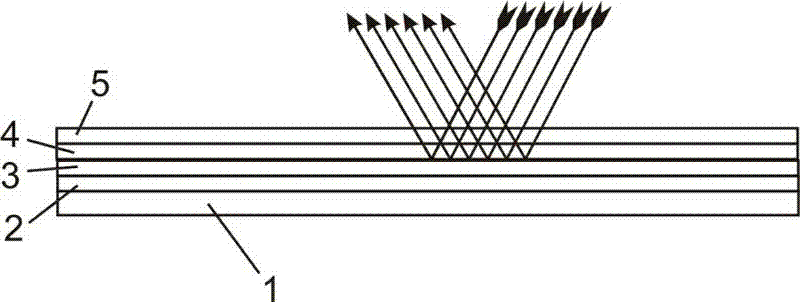

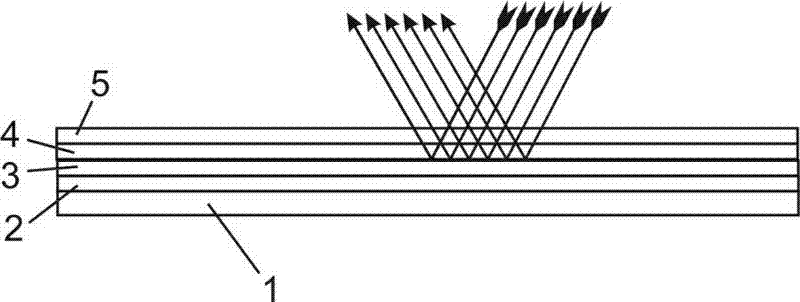

[0042] The present invention is described in further detail below in conjunction with the embodiments shown in the accompanying drawings:

[0043] A method for manufacturing a self-cleaning solar energy nano-film with high reflectivity is implemented, the method comprising the steps of:

[0044] A. First prepare a layer of base layer, which is stainless steel or plexiglass PMMA or plexiglass PET, with a thickness of 0.3mm to 1.2mm, and the surface is cleaned with detergent, washed with distilled water, dried for 1 minute, and ground with a fine grinder 2 minutes, the finish reaches level 13 or above;

[0045] B. Next, prepare a transition layer with copper or chromium on the base layer by magnetron sputtering deposition. The target size of copper or chromium is Ф60×5 mm, the purity is 99.99%, and the sputtering gas is 99.999 % high-purity argon, the background vacuum is 6.1×10 -4 Pa, the working pressure was set to 0.7 Pa, the target-base distance was fixed at 75 mm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com