Biological-chemical combined pretreatment method of lignocellulosic materials

A technology for lignocellulose and microbial treatment, which is used in fiber raw material treatment, pretreatment with acidic compounds, textiles and papermaking, etc., can solve the problems of sugar loss, low efficiency, long pretreatment time, etc. Processing efficiency, the effect of reducing the wrapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

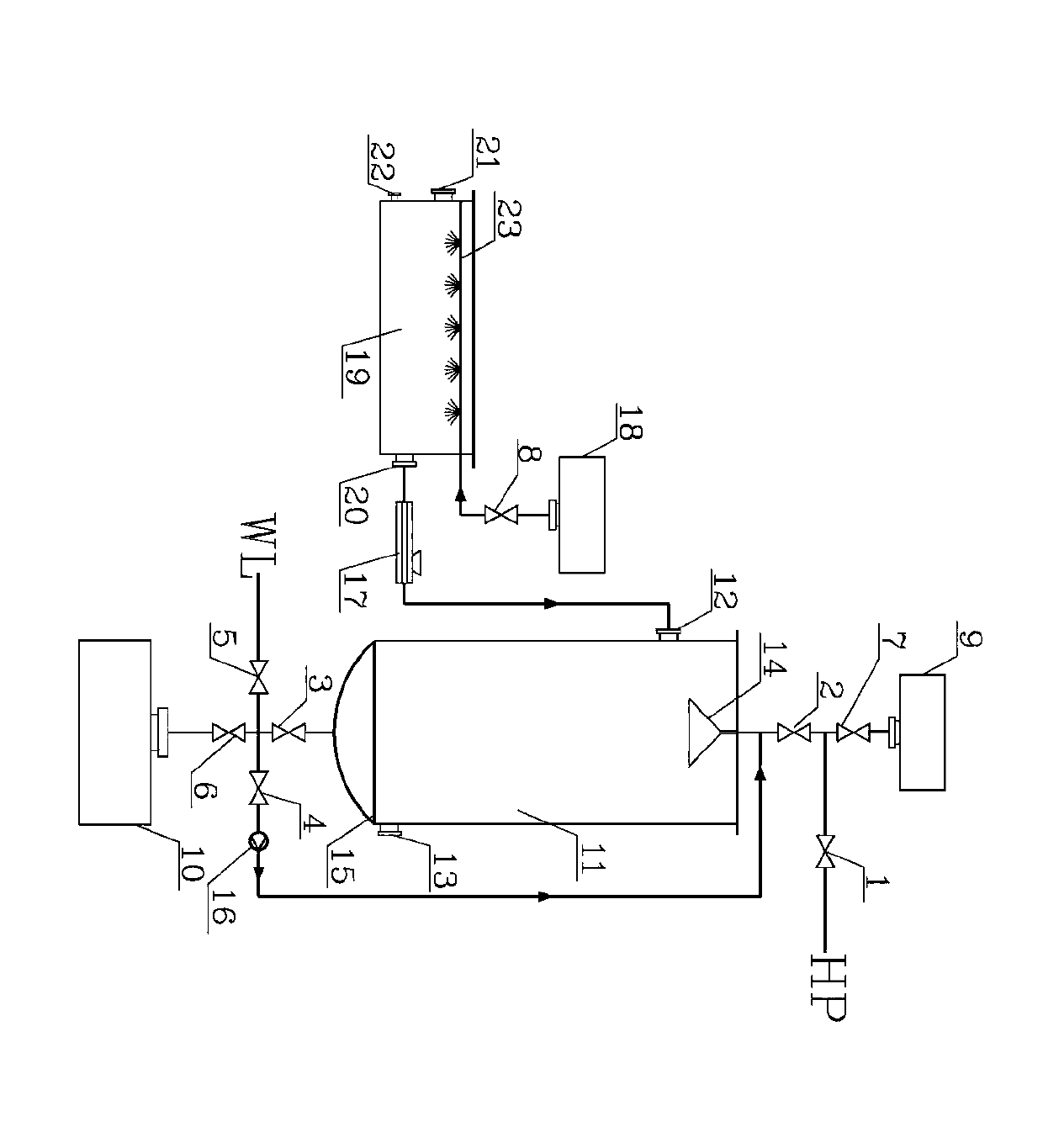

Embodiment 1

[0030] Example 1: After drying corn stalks with constant weight (33.31% cellulose, 26.82% hemicellulose, and 21.46% lignin) to 10 meshes, put them into the microbial treatment tank 19 from the feed port 20, and open the valve 8 1. Inject the cultured Trametes trichotillobacter seed liquid from the strain tank 18, inoculate 5% (weight percent, dry weight), adjust the water content to 65%, open the vent 22, and treat at 30°C for 5 days. Open the discharge port 20, open the material conveyor 17 and load the raw material processed by microorganisms into the dilute acid circulation reactor 11 from the feed port 12, open the valve 1 and the valve 2, and inject 0.5% dilute acid from the acid storage tank 9. Sulfuric acid is placed in the reactor 11, the solid-to-liquid ratio of corn stalks and dilute sulfuric acid is 1:10; open valve 3, valve 4, close valve 1, valve 2, start the circulation pump 16, and circulate the reaction at 90°C for 2h, during the reaction The liquid part is cir...

Embodiment 2

[0031] Example 2: After crushing dried corn stalks (33.31% cellulose, 26.82% hemicellulose, and 21.46% lignin) to 10 meshes, put them into the microbial treatment tank 19 from the feed port 20, and open the valve 8 1. Inject the cultured Trametes versicolor strain solution from the strain tank 18, the inoculation amount is 5% (weight percentage, dry weight), adjust the water content to 65%, open the vent 22, and treat at 30°C for 5 days. Open the discharge port 20, open the material conveyor 17 and load the raw material processed by microorganisms into the dilute acid circulation reactor 11 from the feed port 12, open the valve 1 and the valve 2, and inject 0.5% dilute acid from the acid storage tank 9. Sulfuric acid is placed in the reactor 11, the solid-to-liquid ratio of corn stalks and dilute sulfuric acid is 1:10; open valve 3, valve 4, close valve 1, valve 2, start the circulation pump 16, and circulate the reaction at 90°C for 2h, during the reaction The liquid part is ...

Embodiment 3

[0032] Example 3: The dried corn stalks (cellulose 33.31%, hemicellulose 26.82%, lignin 21.46%) were crushed to 10 meshes and loaded into the microbial treatment tank 19 from the feed port 20, and the valve 8 was opened 1. Inject the cultured Trametes trichotillobacter seed liquid from the strain tank 18, inoculate 5% (weight percent, dry weight), adjust the water content to 65%, open the vent 22, and treat at 30°C for 5 days. Open the discharge port 20, open the material conveyor 17 and load the raw material processed by microorganisms into the dilute acid circulation reactor 11 from the feed port 12, open the valve 1 and the valve 2, and inject 0.5% dilute acid from the acid storage tank 9. Sulfuric acid is placed in reactor 11, the solid-to-liquid ratio of corn stalks and dilute sulfuric acid is 1:10; valve 3 and valve 4 are opened, valve 1 and valve 2 are closed, circulation pump 16 is started, and the reaction is circulated at 85°C for 2 hours. The liquid part is circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com