A method for calcium and magnesium composite enhanced vanadium extraction

A calcium-magnesium and composite material technology, applied in the metallurgical field, can solve the problems of low recovery rate of vanadium in the vanadium extraction process by calcification, and achieve the effects of reducing the encapsulation effect, improving the conversion rate and improving the leaching kinetic conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

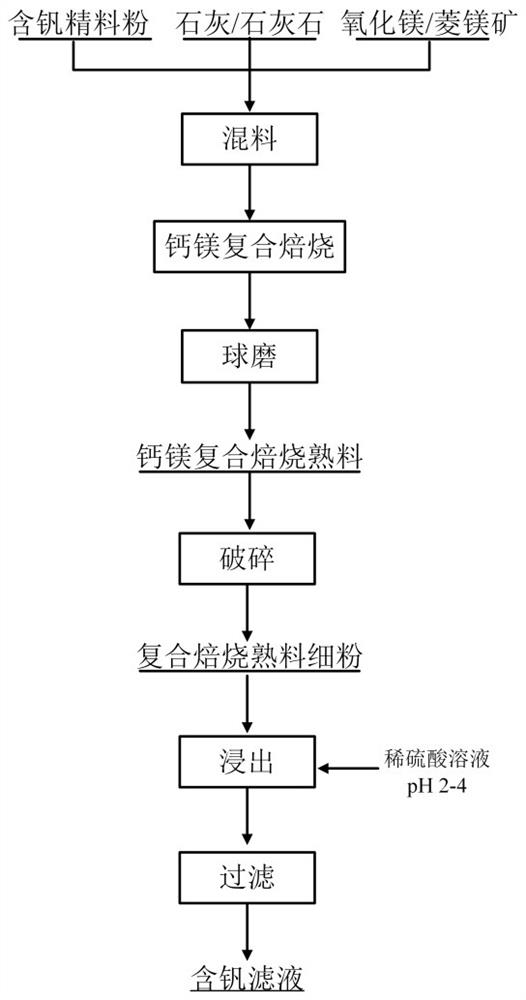

[0023] Embodiment 1: see figure 1 , a method for calcium-magnesium composite enhanced vanadium extraction, comprising the steps of:

[0024] S1: Fully mix converter vanadium slag and limestone in a mixer in a certain proportion to obtain a composite material. The particle size of raw materials used is 100% less than 200 microns, and 85% is less than 100 microns; the molar ratio of Ca and V in the mixture is 1:1.

[0025] S2: Oxidize and roast the composite material in step 1: in a rotary kiln, the oxygen partial pressure in the furnace is 0.21atm, the temperature in the high temperature section is 850°C, the residence time in the furnace is 3h, and the calcium-magnesium composite roasted clinker is obtained by air cooling.

[0026] S3: Milling the calcium-magnesium composite roasted clinker in step 2 in a ball mill to obtain a calcium-magnesium composite roasted clinker fine powder, the particle size of which is 70% less than 75 microns.

[0027] S4: leaching the fine powder...

Embodiment 2

[0029] S1: Fully mix converter vanadium slag, limestone, and magnesite powder in a mixer in a certain proportion to obtain a composite material. The particle size of the raw materials used is 100% less than 200 microns, and 85% is less than 100 microns; the molar ratio of (Ca+Mg): V in the mixture is 1:1, and the molar ratio of Mg to Ca is 5:1.

[0030] S2: The composite material in S1 is oxidized and roasted in a rotary kiln, the oxygen partial pressure in the furnace is 0.21atm, the temperature in the high temperature section is 850°C, the residence time in the furnace is 3h, and the calcium-magnesium composite roasted clinker is obtained by air cooling.

[0031] S3: The calcium-magnesium composite roasted clinker in SS2 is ball-milled in a ball mill to obtain calcium-magnesium composite roasted clinker fine powder, the particle size of which is 70% less than 75 microns.

[0032] S4: Leach the calcium-magnesium composite roasted clinker fine powder in S3 in dilute sulfuric a...

Embodiment 3-11

[0034] Example 3-11: The same method as in Example 2 was adopted, the only difference being the amount of materials used in each step and the reaction conditions, as shown in Table 1 for details.

[0035] In addition, the calcination temperature in S2 does not exceed 850°C, specifically 850°C, 800°C, 750°C or 700°C, and the residence time in the furnace is 1~4h, specifically 1h, 1.5h, 2h, 2.5h, 3h , 3.5h or 4h, the oxygen partial pressure in the furnace is 0.15~0.21atm, specifically 0.15atm, 0.16atm, 0.17atm, 0.18atm, 0.19atm, 0.20atm or 0.21atm, the pH value in S4 is 2-4, Specifically, you can choose 2, 3 or 4.

[0036] Table 1

[0037] (Ca+Mg) / V molar ratio Mg / Ca molar ratio Calcination temperature (℃) Furnace residence time (h) Partial pressure of oxygen in the furnace (atm) Leach pH Leaching time (min) Vanadium recovery rate (%) Example 3 1:2 1:1 850 3 0.21 3.0±0.2 30 79.8 Example 4 1:2 2:1 850 3 0.21 3.0±0.2 30 83.3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com