Organic-inorganic hybridization solar battery and manufacturing method thereof

A solar cell and inorganic technology, applied in the field of solar cells, can solve problems such as low photoelectric conversion efficiency, high battery manufacturing cost, and silicon quality damage, so as to reduce the probability of carrier surface recombination, enhance anti-reflection effect, reduce Effects of Purity Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

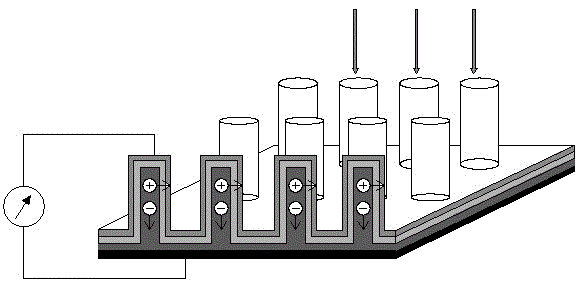

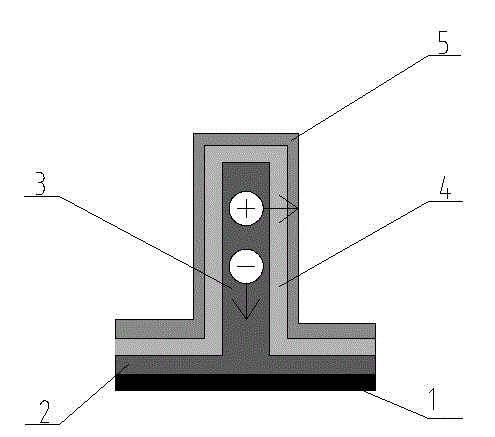

Method used

Image

Examples

Embodiment 1

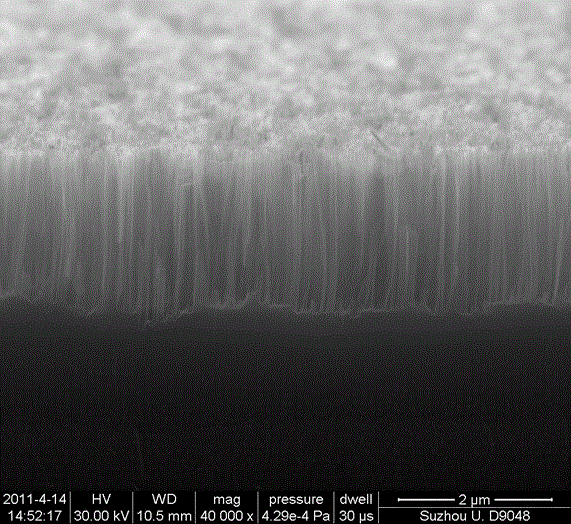

[0050] (1) Use commercial n-type silicon wafers (100) and use chlorobenzene as solvent to prepare spiro-OMeTAD solution for later use; clean the n-type silicon wafers, 3 Etched in the etching solution at room temperature for 20min, and then removed it in 30% (W / W) HNO 3 Soak in the solution for at least 1 hour to remove Ag, then rinse with deionized water to remove residual HNO 3 , to obtain a regular silicon nanowire array, the scanning electron microscope image of the silicon nanowire array is as follows image 3 shown, from image 3 It can be seen that the length of silicon nanowires is in the range of 200-2000 nm, and the distance between nanowires is 50-500 nm;

[0051] (2) In a glove box, the nanowire array was methylated by a two-step chlorination / alkylation method; the scanning electron microscope image of the silicon nanowire array is shown in Figure 4 ;

[0052] (3) Spiro-OMeTAD was then spin-coated on a silicon wafer in a glove box, and the transmission electr...

Embodiment example 2

[0058] (1) Use commercial n-type silicon wafers (100) and use chlorobenzene as solvent to prepare P3HT solution for later use; clean the n-type silicon wafers, and prepare 3 Etched in the etching solution at room temperature for 20min, and then removed it in 30% (W / W) HNO 3 Soak in the solution for at least 1 hour to remove Ag, then rinse with deionized water to remove residual HNO 3 , to obtain a regular silicon nanowire array, the electron microscope image of the silicon nanowire array is as follows image 3 shown, from image 3 It can be seen that the length of silicon nanowires is in the range of 200-2000 nm, and the distance between nanowires is 50-500 nm;

[0059] (2) In a glove box, the nanowire array was methylated by a two-step chlorination / alkylation method; the scanning electron microscope image of the silicon nanowire array is shown in Figure 4 ;

[0060] (3) Spin-coat a layer of P3HT film with a thickness of 50nm on the silicon wafer in the glove box, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com