High-energy flexible electrode material, preparation method thereof and application in secondary battery

A flexible electrode and high-energy technology, applied in the field of electrochemical batteries, can solve the problems of poor cycle performance and difficult capacity of lithium-sulfur battery electrode materials, and achieve excellent flexibility, superior flexibility and conductivity, and superior rate performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

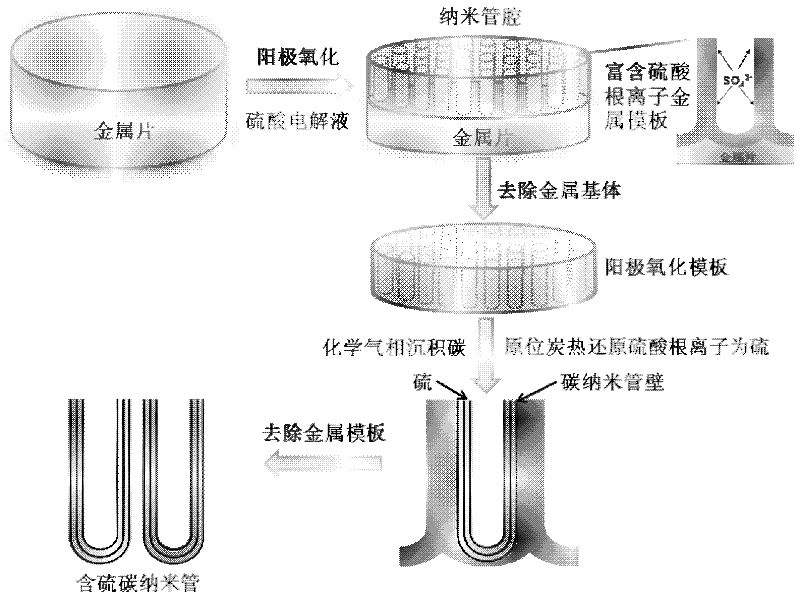

Embodiment 1

[0042] (1) Preparation of alumina template for adsorption of sulfate ions: pure aluminum foil (99.99wt%, 60-200 microns in thickness) is anodized in 15wt% concentration sulfuric acid aqueous electrolyte for 2h, and the reaction temperature is 10°C; through 1mol / L Phosphoric acid and perchromate H 2 CrO 4 The aqueous solution (the volume ratio of phosphoric acid aqueous solution and perchromic acid aqueous solution is 1:1) was treated at 60°C for 0.5h to remove the anodized aluminum film formed for the first time, so that the pore structure of the second anodic oxidation could be more regular, and then Carry out secondary anodic oxidation in 15wt% concentrated sulfuric acid aqueous solution electrolyte for 4h, reaction temperature is 10 ℃, obtains the aluminum oxide porous template that one end opens and adsorbs sulfate ion; The thickness of porous template is 40-50 microns, and the pore size distribution is 20-30 Nano.

[0043] (2) Preparation of carbon nanotube / sulfur compo...

Embodiment 2

[0052] The difference from Example 1 is that

[0053] (1) Preparation process On the basis of Example 1, the concentration of sulfate ions in the electrolyte was changed in this embodiment, and anodic oxidation was carried out in the electrolyte of 30wt% concentration sulfuric acid aqueous solution for 2h, and the reaction temperature was 10°C; by 1mol / L phosphoric acid and perchromic acid aqueous solution (the volume ratio of phosphoric acid aqueous solution and perchromic acid aqueous solution is 1: 1) after 60 ℃ treatment 0.5h, then carry out secondary anodic oxidation 4h in 30wt% concentration sulfuric acid aqueous electrolyte, reaction temperature The temperature is 10°C, and an aluminum oxide porous template with one end open and adsorbing a large amount of sulfate ions is obtained; the thickness of the porous template is 40 microns, and the pore size distribution is 20-30 nanometers.

[0054] (2) Preparation of carbon nanotube / sulfur composite material: place the sulfa...

Embodiment 3

[0057] The difference from Example 2 is that

[0058](1) Preparation process On the basis of Example 2, the time for chemical vapor deposition of carbon was increased. The specific implementation process is as follows: adopt 30wt% concentration sulfuric acid aqueous solution electrolyte to carry out anodic oxidation 2h, reaction temperature is 10 ℃; Pass 1mol / L phosphoric acid and perchromic acid solution (phosphoric acid aqueous solution and perchromic acid aqueous solution volume ratio are 1: 1) After treating at 60°C for 0.5h, carry out secondary anodic oxidation in 30wt% sulfuric acid aqueous electrolyte solution for 4h, the reaction temperature is 10°C, to obtain an alumina porous template with an open end and adsorption of sulfate ions; the thickness of the porous template is 40 microns with a pore size distribution of 15-20 nm.

[0059] (2) Preparation of carbon nanotube / sulfur composite material: Place the sulfate ion-containing alumina template obtained in step (1) i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge specific capacity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com