A kind of preparation method of loaded silver nano particle macroporous material

A technology of silver nanoparticles and macroporous materials, applied in the field of material chemistry, can solve the problems of poor thermal stability, high cost and unsuitable for large-scale production of natural cellulose sheets, and unsuitable for high-temperature applications, and achieve excellent catalytic performance and production Low cost, large surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

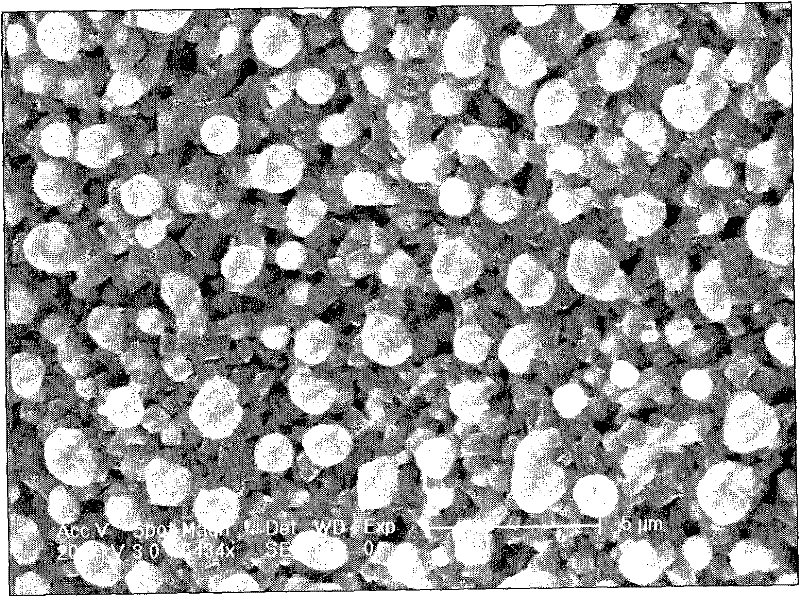

Embodiment 1

[0024] Take commercially available cuttlefish bones, peel them, cut them into pieces, soak them in distilled water, hydrogen peroxide, alcohol, and chloroform respectively for 24 hours, then rinse them with alcohol, dry them, and set them aside. Weigh 0.50g of block cuttlebone in a polytetrafluoroethylene reactor, then weigh 0.66g of diammonium hydrogen phosphate in the reactor in a ratio of 1:1 by the molar ratio of calcium ions and phosphate ions , add 10 ml of distilled water, and seal. React in an oven at a temperature of 180° C. for 24 hours, cool to room temperature naturally after the reaction, rinse with distilled water, and dry at a temperature of 120° C. for 2 to 3 hours. The above product was sintered at a temperature of 900° C. for 1 hour in a crucible resistance furnace. A 0.01 mol / liter silver nitrate solution is prepared, the sintered product is soaked in the silver nitrate solution for 2-3 hours, and then dried at 120° C. for 2-3 hours. In a crucible resistan...

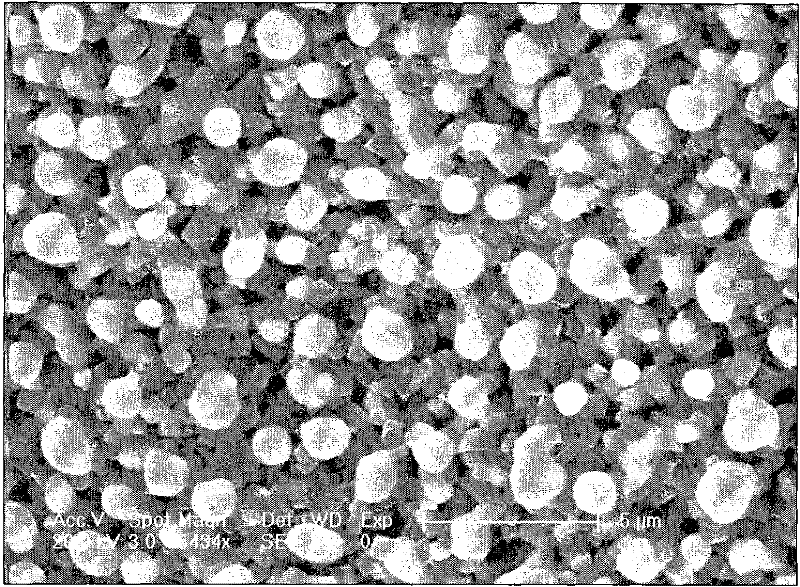

Embodiment 2

[0027] Take commercially available cuttlefish bones, peel them, cut them into pieces, soak them in distilled water, hydrogen peroxide, alcohol, and chloroform respectively for 24 hours, then rinse them with alcohol, dry them, and set them aside. Weigh 0.50g of block cuttlebone in a polytetrafluoroethylene reactor, then weigh 1.32g of diammonium hydrogen phosphate in the reactor in a ratio of 1:2 by the molar ratio of calcium ions and phosphate ions , add 10 ml of distilled water, and seal. React in an oven at a temperature of 150° C. for 24 hours, cool to room temperature naturally after the reaction, rinse with distilled water, and dry at a temperature of 120° C. for 2 to 3 hours. The above product is sintered at a high temperature of 900° C. for 1 to 2 hours in a crucible resistance furnace. Prepare a 0.50 mol / liter silver nitrate solution, soak the sintered product in the silver nitrate solution for 2-3 hours, and then dry it at 120° C. for 2-3 hours. In a crucible resist...

Embodiment 3

[0030] Take commercially available cuttlefish bones, peel them, cut them into pieces, soak them in distilled water, hydrogen peroxide, alcohol, and chloroform respectively for 24 hours, then rinse them with alcohol, dry them, and set them aside. Weigh 0.50g of block cuttlebone in a polytetrafluoroethylene reactor, then weigh 1.98g of diammonium hydrogen phosphate in the reactor in a ratio of 1:3 by the molar ratio of calcium ions and phosphate ions , add 10 ml of distilled water, and seal. React in an oven at a temperature of 120-180° C. for 48 hours, cool to room temperature naturally after the reaction, rinse with distilled water, and dry at a temperature of 120° C. for 2 to 3 hours. The above product was sintered at a temperature of 900° C. for 1 hour in a crucible resistance furnace. Prepare a 1.0 mol / liter silver nitrate solution, soak the sintered product in the silver nitrate solution for 2-3 hours, and then dry it at 120° C. for 2-3 hours. In a crucible resistance fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com