High-thermostability ordered mesoporous carbon material and preparation method thereof

A technology of high thermal stability and mesoporous carbon, applied in the field of preparation of porous materials, can solve the problems of metal equipment corrosion and environmental pollution, and achieve the effects of reducing corrosion, cheap and easy-to-obtain raw materials, and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Dissolve resorcinol and surfactant F127 in a mixed system of 20g ethanol and 20g distilled water, stir vigorously to dissolve them all, then add 2.1g citric acid;

[0022] 2) After stirring for 2 hours, add 2.5g of 37% formaldehyde solution (the molar ratio of formaldehyde to citric acid is 3), and continue to stir to make it start to polymerize slowly to obtain the oligomeric resol resin / F127 complex;

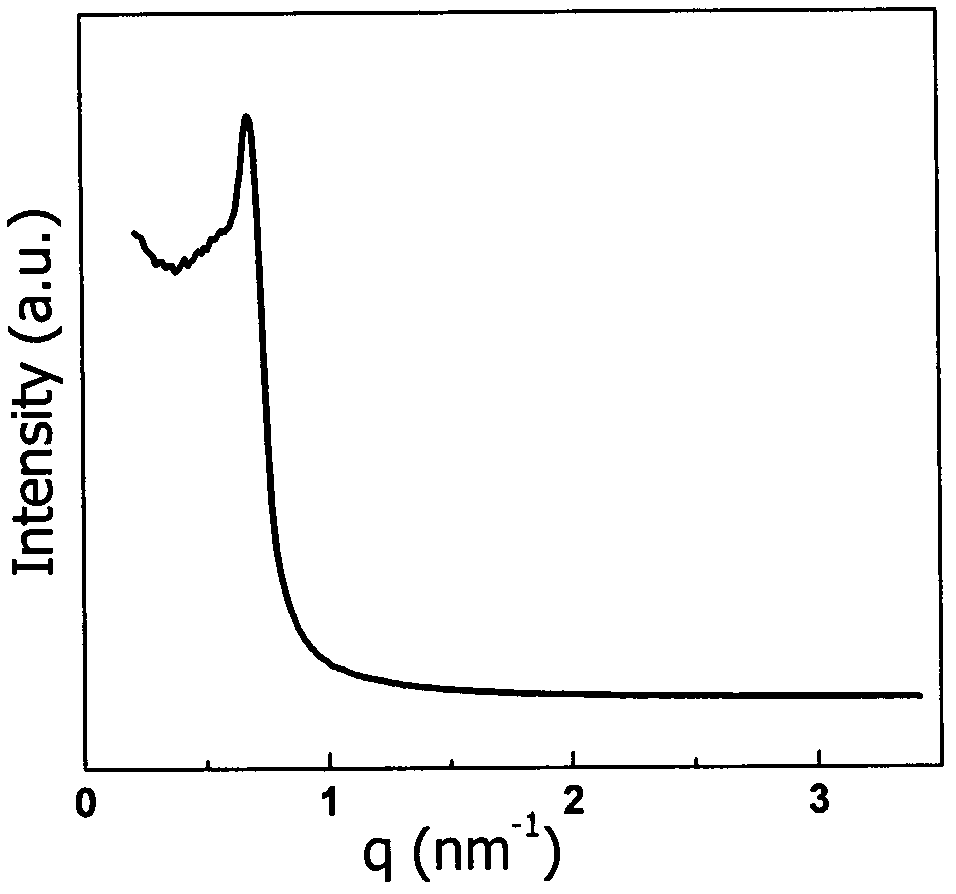

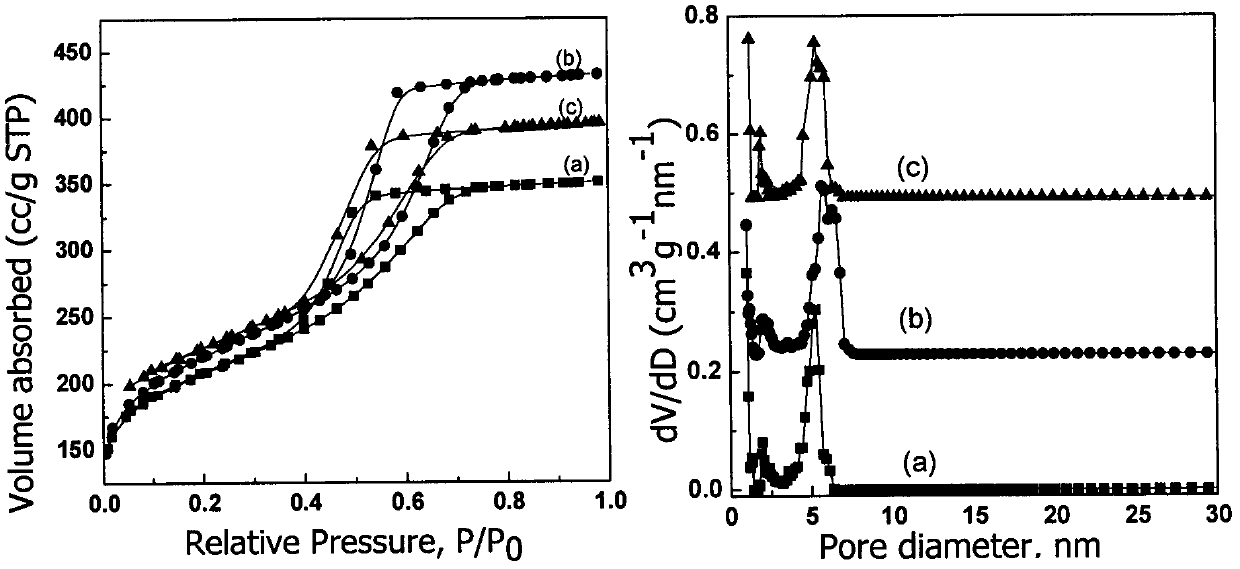

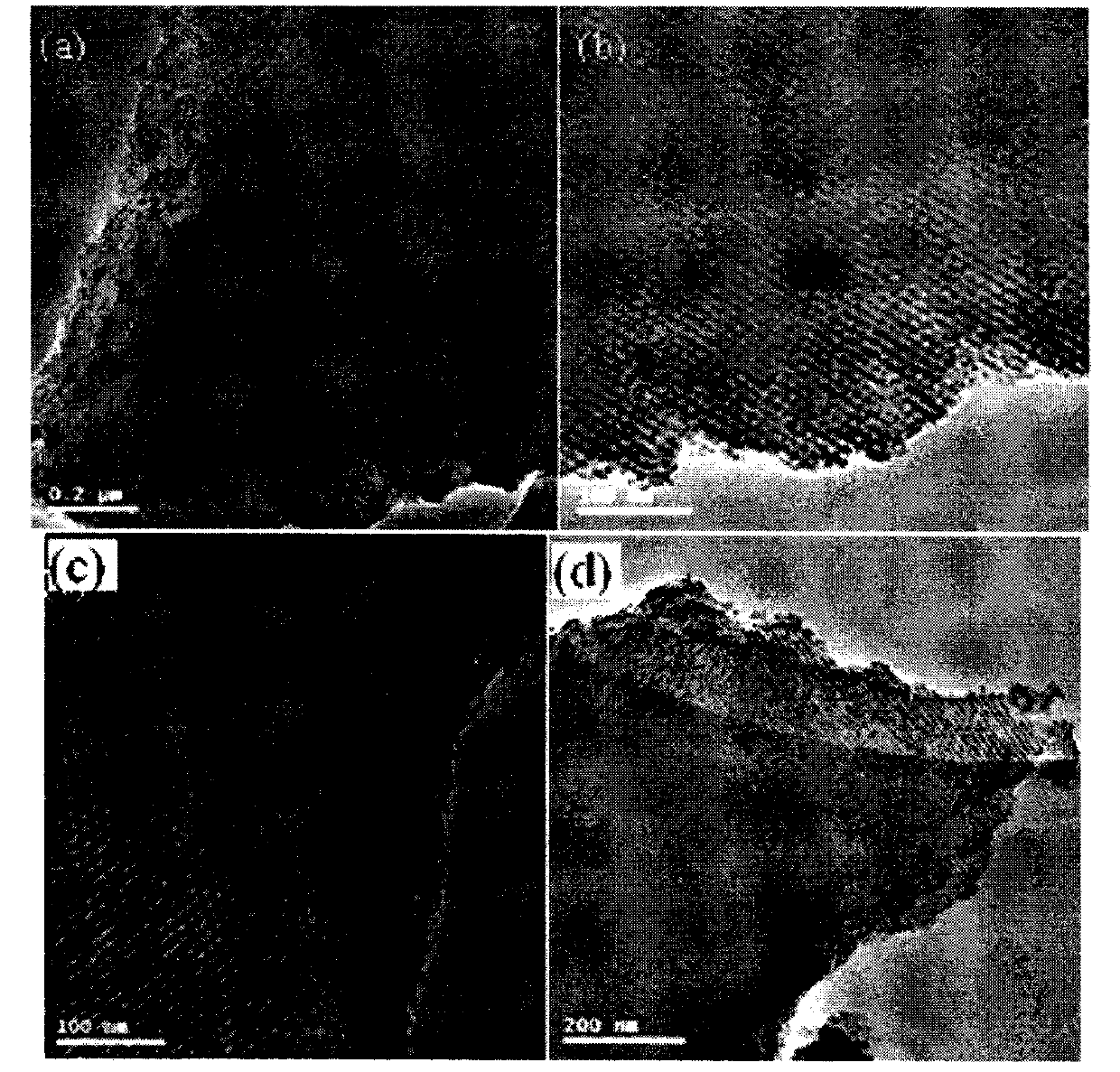

[0023] 3) After the reaction was carried out for 2 hours, a light yellow clear and transparent solution was obtained, which was transferred to a 50ml reaction kettle and aged at 60°C for two days to obtain an elastic orange-red polymer / surfactant solid composite, which was carbonized at 600°C for 3h Finally, the ordered mesoporous carbon material was obtained with a specific surface area of 758m 2 g -1 , the total pore volume is 0.55cc / g, the micropore volume is 0.16cc / g, and the mesopore diameter is about 5.2nm.

Embodiment 2

[0025] Same as Example 1, the amount of citric acid in step 1) is reduced to 1.0g (the molar ratio of formaldehyde to citric acid is 6), other reaction conditions remain unchanged, the final mixed solution is transferred to a 50ml reaction kettle, 60°C After aging for two days, an elastic orange-red polymer / surfactant solid composite was obtained. After washing, drying, and carbonization at 600°C for 3 hours, an ordered mesoporous carbon material was obtained, with a specific surface of 770m 2 g -1 , the total pore volume is 0.52cc / g, the micropore volume is 0.15cc / g, and the mesopore diameter is about 5.6nm.

Embodiment 3

[0027] Same as in Example 1, reduce the amount of citric acid used in step 1) to 0.5g (the molar ratio of formaldehyde to citric acid is 15), keep other reaction conditions unchanged, transfer the final mixed solution into a 50ml reactor, and age at 60°C After two days, an orange-red polymer / surfactant solid composite was obtained, which was washed, dried, and carbonized at 600°C for 3 hours to obtain an ordered mesoporous carbon material with a specific surface of 736m 2 g -1 , the total pore volume is 0.54cc / g, the micropore volume is 0.13cc / g, and the mesopore diameter is about 5.2nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com