A kind of preparation method and application of nano-alumina

A nano-alumina and nano-alumina technology, which is applied in the field of preparation of inorganic nano-materials, can solve the problems of cost limitation, high price, complicated process, etc., and achieve the effects of mild preparation conditions, adjustable pore distribution, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

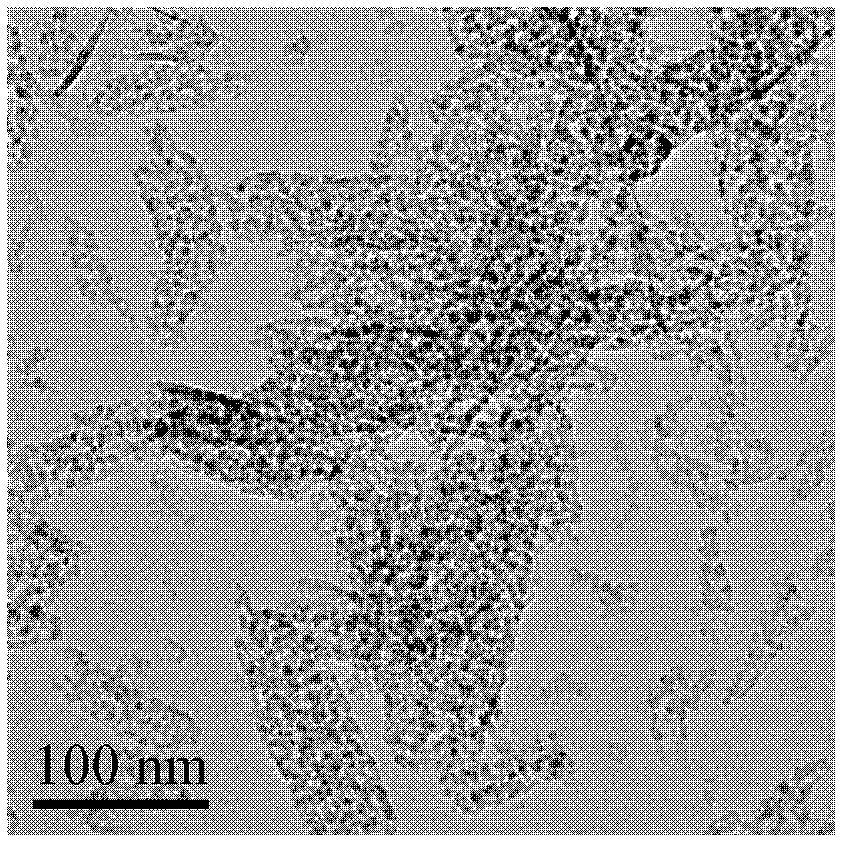

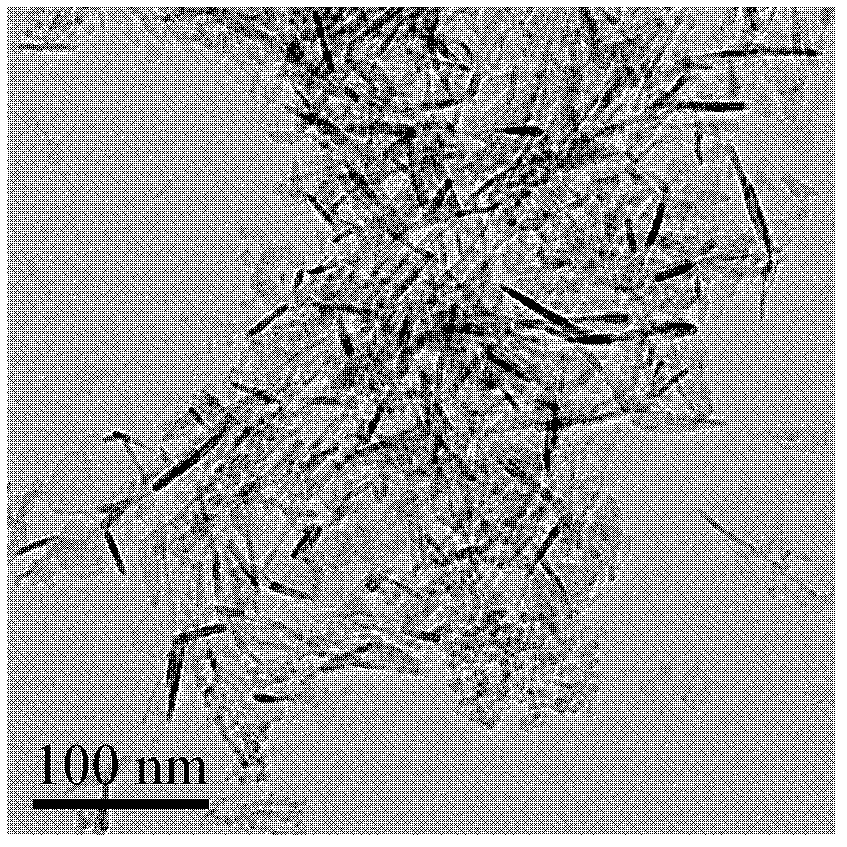

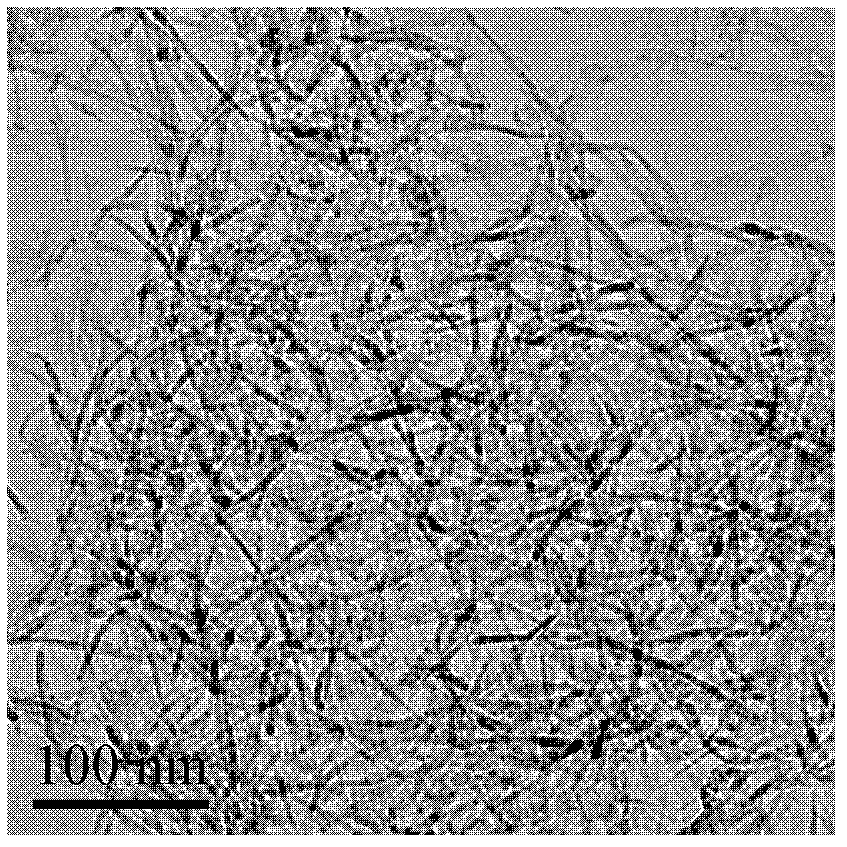

Image

Examples

Embodiment 1

[0045] Dissolve 10g of aluminum nitrate into 50ml of ethanol, add 0.3ml of acetic acid (glacial acetic acid, ≥99.5%) under stirring at 80°C, then add ammonium carbonate solution (1.0mol / L) under stirring until the pH of the mixed liquid is 9.5, and continue stirring for 2 After 1 hour, it was aged at 80°C for 24 hours, and the precipitate was filtered out, dried at 110°C for 12 hours, and calcined at 600°C for 5 hours to obtain sample S1, whose physical adsorption data are listed in Table 1.

Embodiment 2

[0047] Dissolve 10g of aluminum nitrate into 50ml of ethanol, add 0.3ml of acetic acid (glacial acetic acid, ≥99.5%) under stirring at 80°C, then add ammonium carbonate solution (1.0mol / L) under stirring until the pH of the mixed liquid is 8.5, and continue stirring for 2 After 1 hour, it was aged at 80°C for 24 hours, and the precipitate was filtered out, dried at 110°C for 12 hours, and calcined at 600°C for 5 hours to obtain sample S2, whose physical adsorption data are listed in Table 1.

Embodiment 3

[0049] Dissolve 10g of aluminum nitrate in 50ml of ethanol, add 0.3ml of acetic acid (glacial acetic acid, ≥99.5%) under stirring at 70°C, then add ammonium carbonate solution (1.0mol / L) under stirring until the pH of the mixed liquid is 7.5, and continue stirring for 2 After 1 hour, it was aged at 80°C for 24 hours, the precipitate was filtered out, dried at 110°C for 12 hours, and then calcined at 600°C for 5 hours to obtain sample S3, whose physical adsorption data are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com