A kind of aluminum oxide hollow sphere thermal insulation product

An alumina hollow ball and alumina technology, which is applied in the field of refractory materials, can solve the problems of poor thermal shock stability, high service temperature and high raw material cost, and achieve the effects of stable performance, improved thermal shock resistance and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

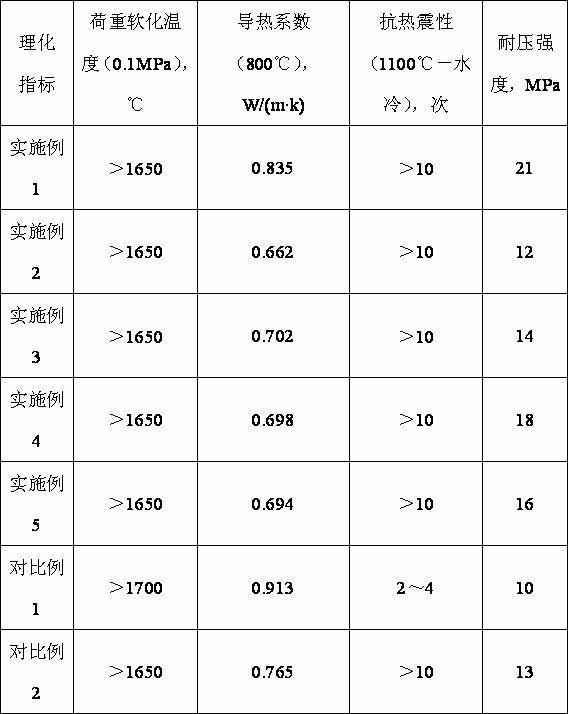

Examples

Embodiment 1

[0024] Example 1: The mass percent of each component is: 4-0.1 mm aluminum oxide hollow spheres (the hollow spheres are made of waste corundum-mullite bricks and sintered Al 2 o 3 The fine powder is made by melting and blowing raw materials in a three-phase electric arc furnace. The mass percentage of raw materials added is: waste corundum-mullite brick 50%, sintered Al 2 o 3 Fine powder 50%; Al in hollow sphere 2 o 3 The total mass percentage is 94%) 55%, 2 o 3 The total mass percentage is 92.4%) 40%, 2 o 3 Fine powder (Al 2 o 3 >98.0%) 5%.

[0025] In addition, the phosphate salt solution is added, and the addition amount of the phosphate solution is 14% of the total weight of the product.

Embodiment 2

[0026] Example 2: The mass percentage of each component is: 4-0.1 mm aluminum oxide hollow balls (the hollow balls are made by melting and blowing waste corundum bricks and waste corundum-mullite bricks in a three-phase electric arc furnace, The mass percentages of raw materials added are: 80% of waste corundum bricks, 20% of waste corundum-mullite bricks; Al in hollow spheres 2 o 3 The total mass percentage is 96.4%) 75%, 2 o 3 The total mass percentage is 90.1%) 5%, 2 o 3 Fine powder (Al 2 o 3 >98.0%) 20%.

[0027] Add lignosulfonate aqueous solution in addition, the addition amount of lignosulfonate aqueous solution is 6% of product gross weight.

Embodiment 3

[0028]Example 3: The mass percentage of each component is: 3-0.2 mm alumina hollow balls (the hollow balls are made of waste corundum bricks, waste corundum-mullite bricks, and waste alumina hollow ball bricks in three-phase arc Furnace melting and blowing, the mass percentage of raw materials added is: 30% of waste corundum bricks, 40% of waste corundum-mullite bricks, 30% of waste alumina hollow ball bricks; 2 o 3 The total mass percentage is 93.8%) 60%, 2 o 3 The total mass percentage is 90.1%) 10%, 2 o 3 Fine powder (Al 2 o 3 >98.0%) 30%.

[0029] Add sulfuric acid brine solution in addition, the add-on of sulfate brine solution is 12% of product gross weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com