Preparation method of diethyl N,N-bis(2- hydroxyethyl) aminomethylphosphonate

A technology of diethyl aminomethylphosphonate and diethyl phosphite, applied in the N field, can solve the problems of affecting product quality and later application, increasing energy consumption of production processes, unfavorable industrialized production, etc., and achieving high product yield , The effect of reducing the amount of catalyst and shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

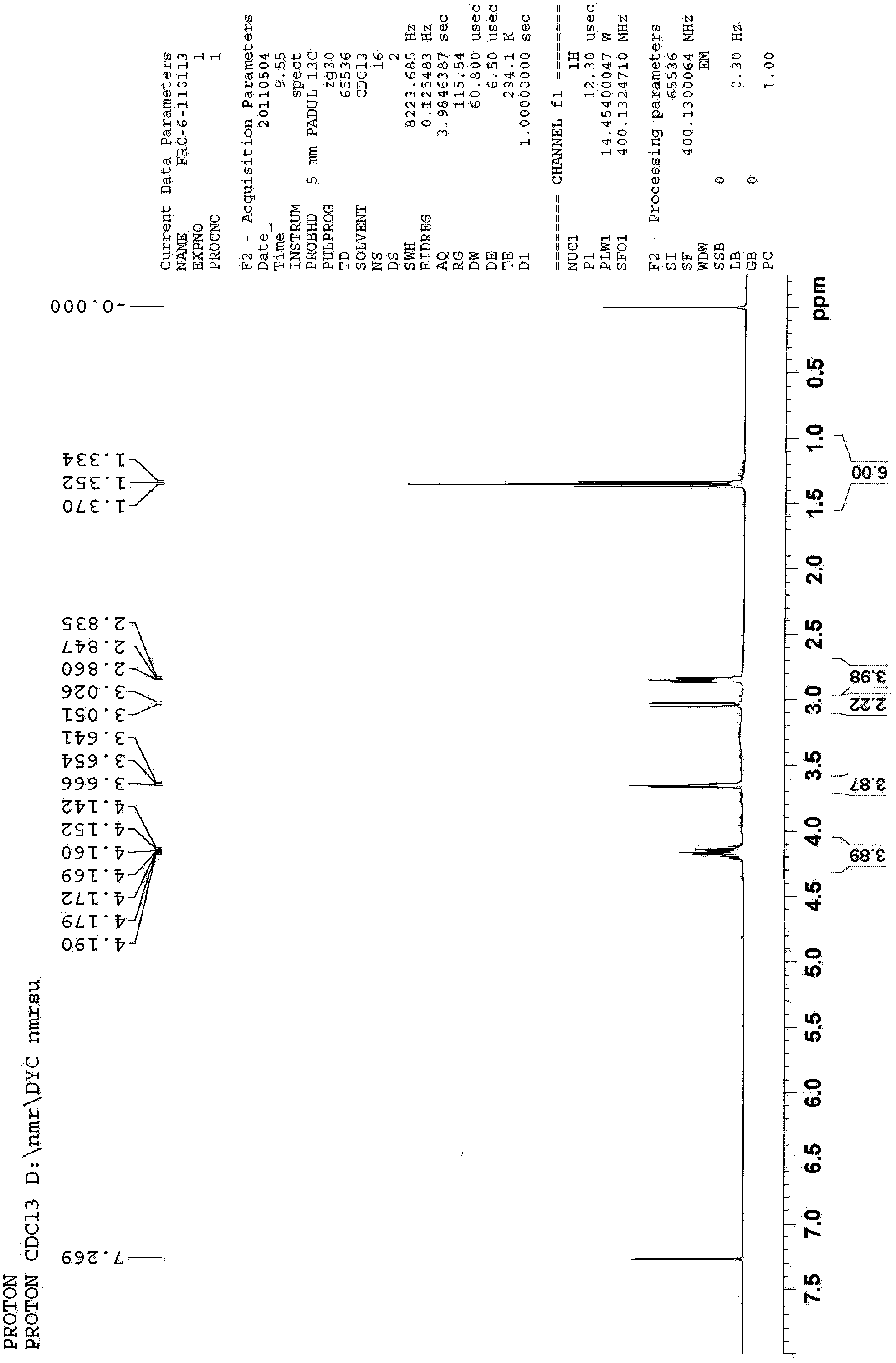

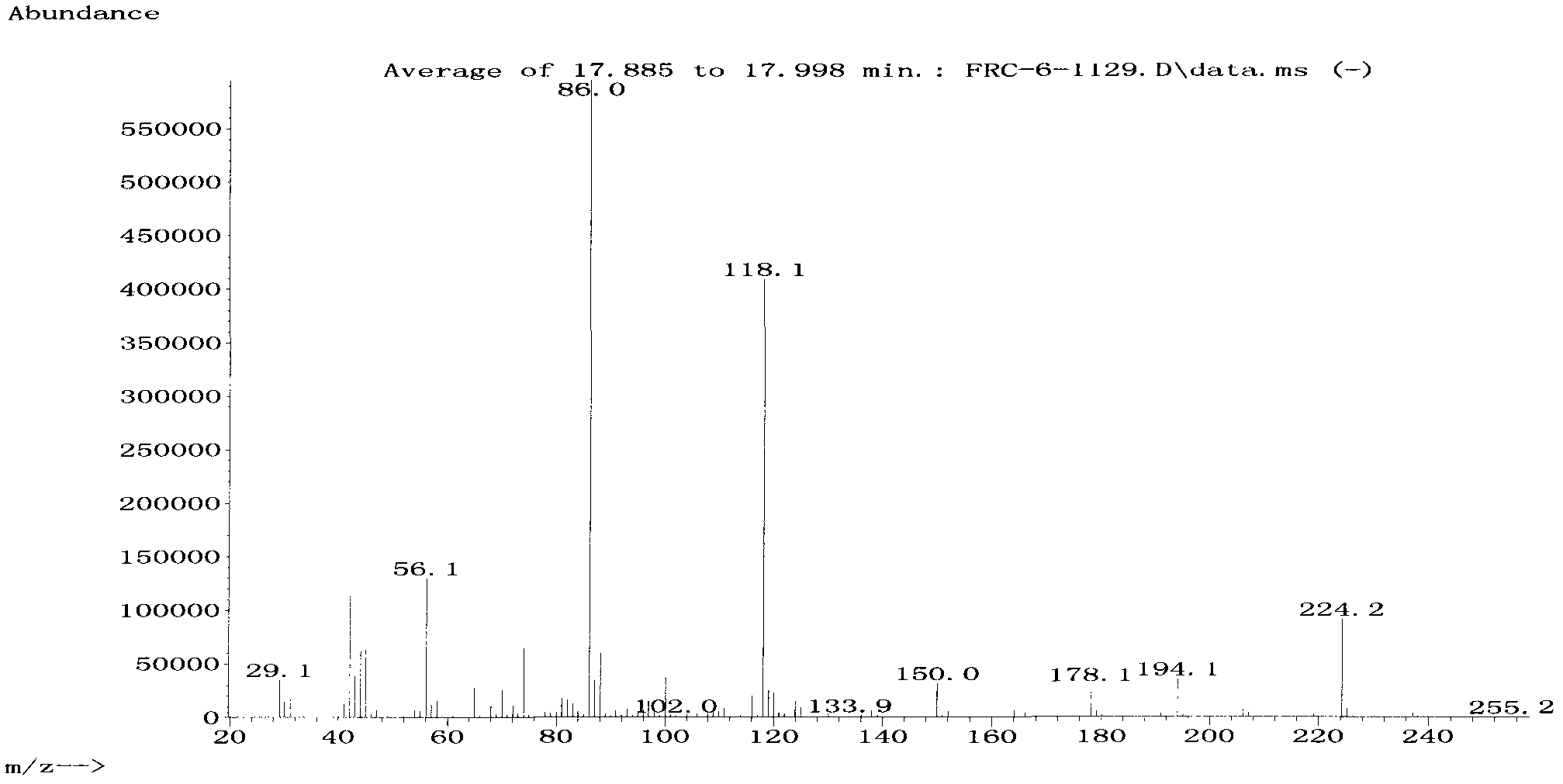

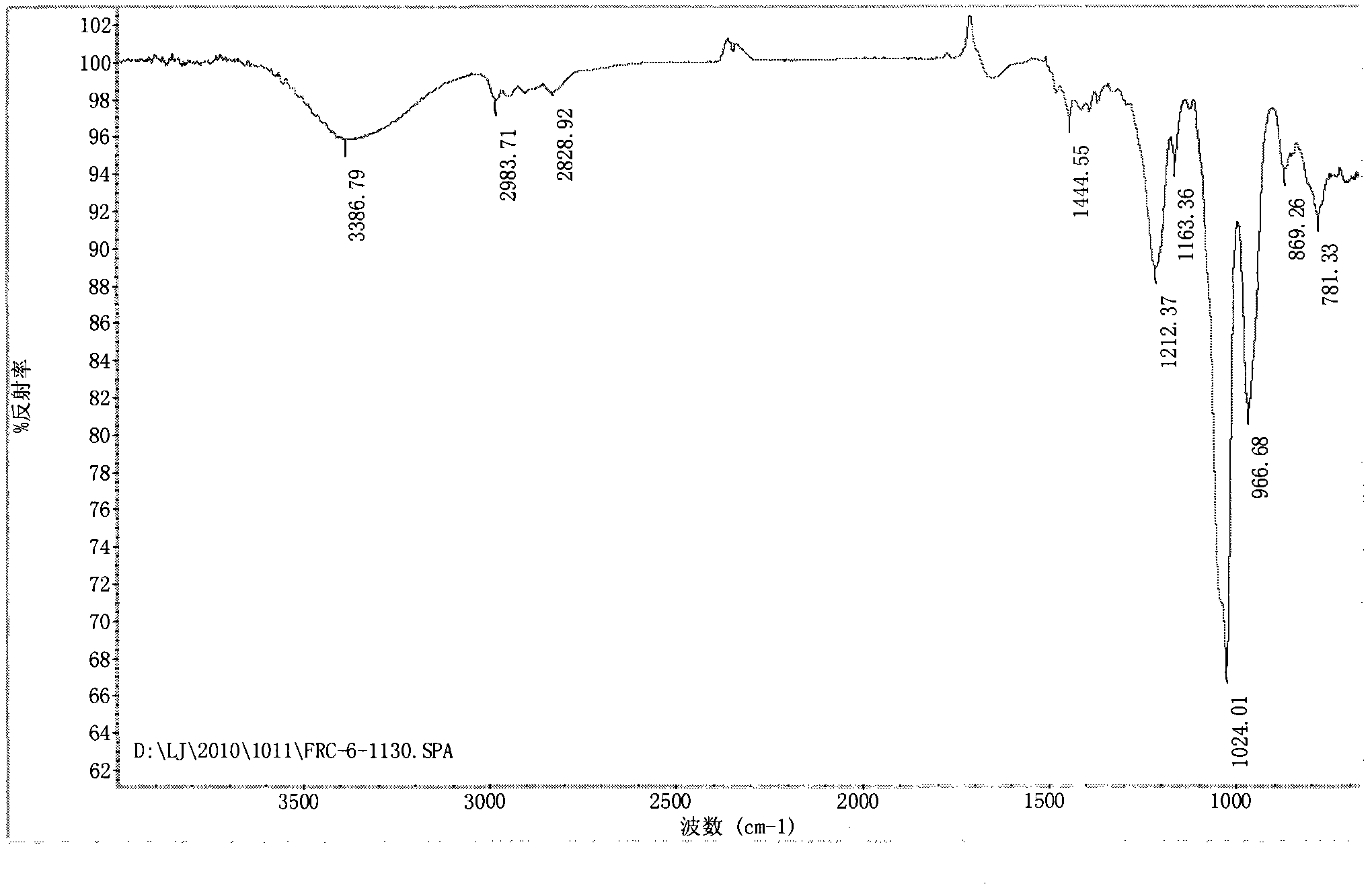

Image

Examples

Embodiment 1

[0032] 1. Weigh 360 parts of n-propanol in a 2L three-neck flask equipped with a magnetic stirrer, a constant pressure dropping funnel and a thermometer, raise the temperature to 70°C, add 180 parts of paraformaldehyde solid, and adjust the polyformaldehyde with sodium hydroxide solution The pH of the formaldehyde solution is 9-11, until the paraformaldehyde is completely dissolved, and the temperature is lowered to 30°C.

[0033] 2. Weigh 78 parts of anhydrous sodium sulfate into a three-necked flask, weigh 573 parts of diethanolamine in a constant pressure dropping funnel, slowly add diethanolamine under stirring, the reaction is an exothermic reaction, control the reaction temperature at 40°C , after the dropwise addition of diethanolamine was completed, the temperature was kept at 40° C., and the reaction was continued for 1 hour. Then the temperature was lowered to 30°C, and the sodium sulfate after absorbing water was removed by filtration.

[0034]3. Raise the temperat...

Embodiment 2

[0047] 1. Weigh 222 parts of n-butanol in a 2L three-neck flask with a magnetic stirrer, a constant pressure dropping funnel and a thermometer, raise the temperature to 80°C, add 180 parts of paraformaldehyde solid, and adjust the polyformaldehyde with sodium hydroxide solution The pH of the formaldehyde solution is 9-11, until the paraformaldehyde is completely dissolved, and the temperature is lowered to 30°C.

[0048] 2. Weigh 100 parts of calcium oxide into a three-necked flask, weigh 623.8 parts of diethanolamine in a constant pressure dropping funnel, slowly add diethanolamine under stirring, the reaction is an exothermic reaction, control the reaction temperature at 40°C, After the ethanolamine was added dropwise, the temperature was raised to 50° C., and the reaction was continued for 0.5 hours. Then the temperature was lowered to 30°C, and the calcium oxide after absorbing water was removed by filtration.

[0049] 3. Raise the temperature to 45-50°C, under the condit...

Embodiment 3

[0053] 1. Weigh 700 parts of isopropanol in a 2L three-neck flask equipped with a magnetic stirrer, a constant pressure dropping funnel and a thermometer, raise the temperature to 60°C, add 180 parts of paraformaldehyde solid, and adjust the polyformaldehyde with sodium hydroxide solution The pH of the formaldehyde solution is 9-11, until the paraformaldehyde is completely dissolved, and the temperature is lowered to 30°C.

[0054] 2. Weigh 80 parts of anhydrous calcium sulfate into a three-necked flask, weigh 519.8 parts of diethanolamine in a constant pressure dropping funnel, slowly add diethanolamine under stirring, the reaction is an exothermic reaction, control the reaction temperature at 30°C , after the addition of diethanolamine was completed, the temperature was kept at 30° C., and the reaction was continued for 2 hours. Calcium sulfate after absorbing water was removed by filtration.

[0055] 3. Raise the temperature to 45-50°C, under the condition that the degree ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com