Polypropylene composition for vehicle and its preparation method

A polypropylene composition and polypropylene technology are used in the preparation of low-emission polypropylene compositions and in the field of low-emission polypropylene compositions for vehicles, which can solve the problem of reducing the effective action time of the remover, inability to add oil substances, and physical adsorption. There are no problems such as increasing the effective action time, the product yield is high, and the equipment requirements are low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

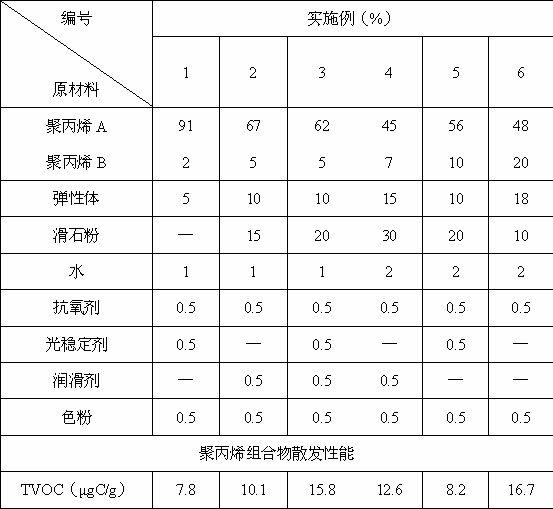

[0031] Take the components shown in table 1 by weight percentage: polypropylene copolymer, high melt strength polypropylene, elastomeric ethylene-propylene copolymer, water and auxiliary agent antioxidant, light stabilizer, toner; Mix in a high-speed mixer for 1 minute, then add talcum powder and mix for 3 minutes to obtain a premix; the premix is melted and extruded by a twin-screw extruder, and the finished product is obtained by secondary vacuum granulation, and its comprehensive properties are measured. The specific values are listed in Table 1.

Embodiment 2

[0033] Take the components shown in table 1 by weight percentage: copolymerized polypropylene, polypropylene with high melt strength, elastomeric ethylene-butylene copolymer, water and additive antioxidant, lubricant, toner; Mix in the mixer for 1 minute, then add talcum powder and mix for 3 minutes to obtain a premix; the premix is melted and extruded by a twin-screw extruder, and the finished product is obtained by secondary vacuum granulation, and its comprehensive properties are measured. The values are listed in Table 1.

Embodiment 3

[0035] Take the components shown in Table 1 by weight percentage: copolymerized polypropylene, high-melt strength polypropylene, elastomer ethylene-octene copolymer, water and auxiliary antioxidant, light stabilizer, lubricant, toner , the preparation method is the same as in Example 1, and its comprehensive properties are measured, and the specific values are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com