A kind of preparation method of biaxially stretched polyvinyl fluoride film

A technology of polyvinyl fluoride and biaxial stretching, which is applied in the field of biaxially stretched polyvinyl fluoride film preparation, can solve the problems of low latent solvent content, excessive latent solvent volatilization, and inability to ensure continuous transverse stretching, etc., to achieve uniformity Good, overcoming operational complexity, and expanding the application field of thin films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

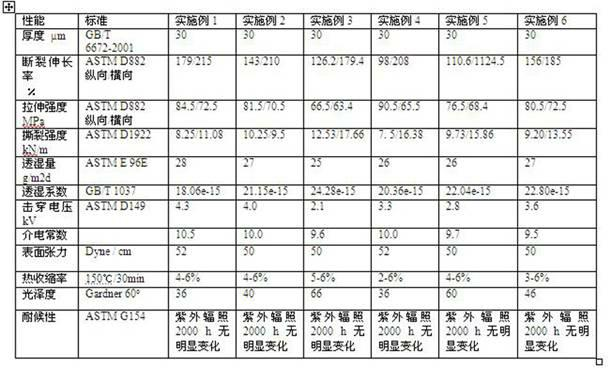

Examples

Embodiment 1

[0034] Add polyvinyl fluoride resin (molecular weight 1,000,000) 100kg, γ-butyrolactone 180kg, plasticizer dioctyl phthalate (DOP) 5kg, titanium dioxide 20kg, pigment carbon black (C) 0.2kg in the mixing mixer, Stir for about 20 minutes to obtain a slurry with a viscosity of 1.0 cpa.

[0035] The slurry is extruded into cast sheets through a twin-screw extruder and a die, and the cast sheets are cooled and shaped at 40°C by a cooling hub.

[0036] Then carry out longitudinal stretching on stretching rollers, longitudinal stretching is 4 times, stretching temperature is 100°C, and transverse stretching is carried out on a horizontal stretching machine, said transverse stretching is 4 times, stretching temperature is 130°C.

[0037] 170°C negative pressure suction and then connected to a condenser tube to collect, remove the residual latent solvent on the film, collect volatile components (mainly latent solvent), control the temperature range of 190°C for shaping to obtain a ...

Embodiment 2

[0040] Add polyvinyl fluoride resin (molecular weight 1500000) 100kg, γ-butyrolactone 200kg, plasticizer dioctyl phthalate (DOP) 5kg, titanium dioxide 20kg, pigment carbon black (C) 0.2kg in the mixing mixer, Stir for about 20 minutes to obtain a slurry with a viscosity of 1.1 cpa. The slurry is extruded into cast sheets through a twin-screw extruder and a die, and the cast sheets are cooled and shaped by a cooling hub at 40°C.

[0041] After longitudinal stretching for 5 times, the stretching temperature is 110°C, and transverse stretching is carried out on a horizontal stretching machine, and the transverse stretching is 3 times, and the stretching temperature is 135°C.

[0042] Pumping and devolatilization at 170°C, collecting volatile components (latent solvent), and setting at 190°C to obtain a biaxially oriented polyvinyl fluoride film. The shaped film is corona treated (380 volts, 20kHz), and the surface energy of the film is 50 dynes.

[0043]

Embodiment 3

[0045] Add 100kg of polyvinyl fluoride resin (molecular weight: 2,000,000), 150kg of N,N-dimethylformamide (DMF), 5kg of plasticizer dioctyl phthalate (DOP), 20kg of titanium dioxide, and pigment carbon into the mixer Black (C) 0.2kg, stirred for about 20 minutes to obtain a slurry with a viscosity of 1.2cpa. The slurry is extruded into cast sheets through a twin-screw extruder and a die head, and the cast sheets are cooled and shaped by a cold hub at 30°C, and then stretched longitudinally by 2 times at a stretching temperature of 90°C and transversely stretched by 7 times at a stretching temperature of 140°C °C, devolatilization at 150 °C, and setting at 170 °C to obtain a biaxially oriented polyvinyl fluoride film. The qualitative film was corona treated (380 volts, 20kHz), and the surface energy of the film was 52 dynes.

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface energy | aaaaa | aaaaa |

| Surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com