Grenadine juice

A technology of pomegranate juice and pomegranate, which is applied in the field of pomegranate juice and its preparation, can solve problems such as precipitation and protein denaturation, and achieve the effects of delicate taste, preventing browning, and prolonging the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

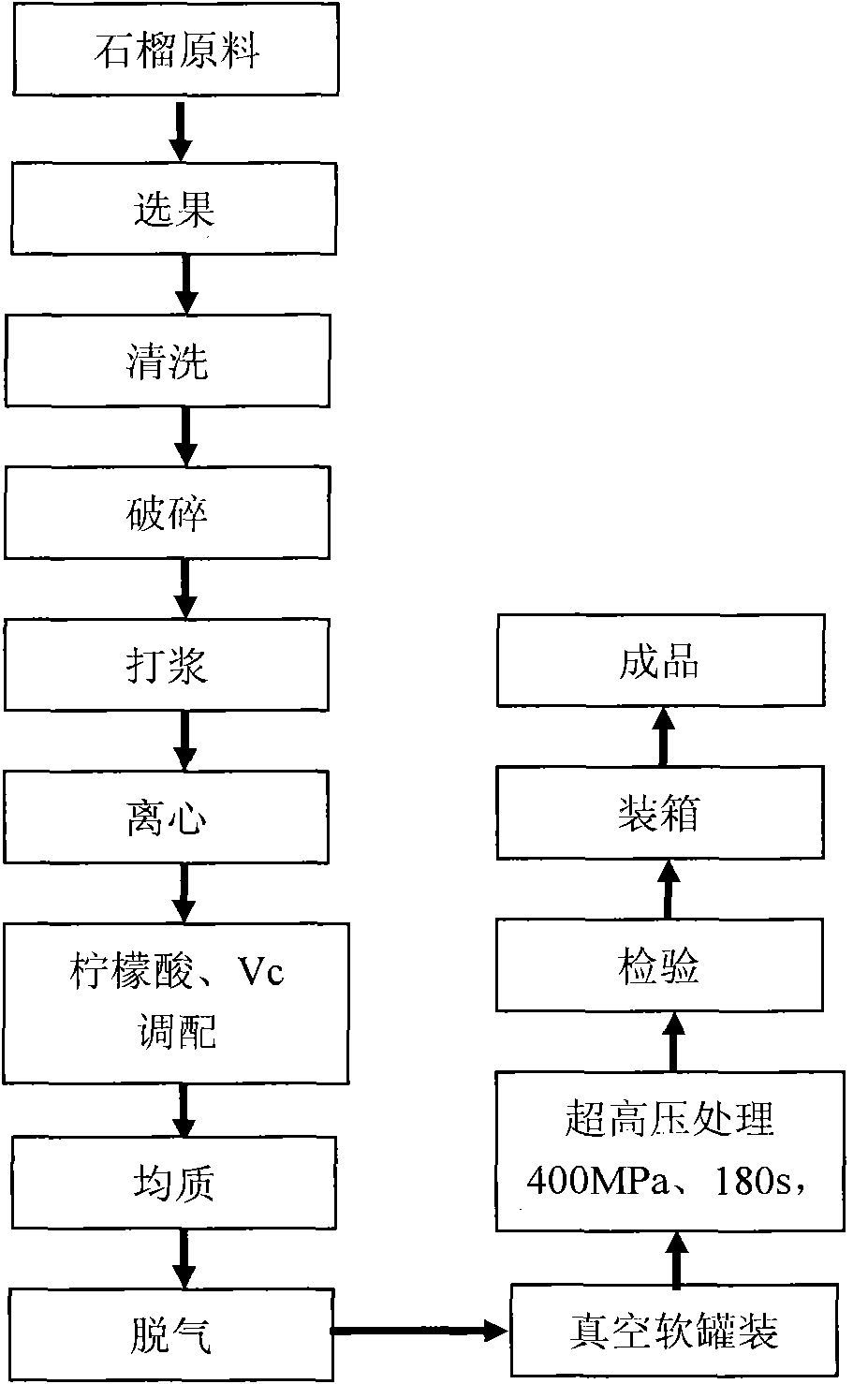

[0020] For the process flow chart of this embodiment, see figure 1 . details as follows:

[0021] (1) Fruit selection: select pomegranate raw materials that are free from mildew, pests, and damage;

[0022] (2) Washing: Soak the pomegranate in water for 1 hour, make it absorb the water, and then use an automatic fruit washer to clean the above-mentioned fruits. The fruits are washed at least three times;

[0023] (3) Crushing: The pomegranate that has been washed and drained is crushed with a fruit crusher;

[0024] (4) Beating: After the crushed fruit is beaten with a beating machine, the slag is discharged and the juice is taken;

[0025] (5) Centrifugation: the fruit pulp is separated by a centrifuge (120 mesh nylon cloth). The centrifugal speed of the juice separation is 8000r / min. There are no large particles suspended in the separated juice. Among them, the centrifuge is Continuous type, continuous feeding and separation, the juice obtained after centrifugation is 100% pomegran...

Embodiment 2

[0042] The mixing ratio of step (6) in Example 1 was changed to add 100 mg of vitamin C and 1 g of citric acid per 1 kg of 100% pomegranate juice, and the treatment conditions of step (10) were changed to 600MPa ultra-high pressure treatment at room temperature for 90s ; Other operating steps are the same as in Example 1. The test results of the obtained pomegranate juice are shown in Tables 3 and 4.

[0043] Table 3 Physical and chemical indexes of pomegranate juice prepared in Example 2

[0044] project unit of measurement index Soluble solids (20 ℃ , Refractometer method) % ≥12 Total acidity (as citric acid) % ≥0.18 Vitamin C mg / kg ≥200 Vitamin B 1 mg / kg 0.5 Vitamin B 2 mg / kg 0.3

[0045] arsenic mg / kg ≤0.2 lead mg / kg ≤0.5 Food preservatives / no

[0046] Table 4 Microbial indicators of pomegranate juice prepared in Example 2

[0047] project unit of measurement index Total number of colonies Pcs / ml ≤100 Coliform count Pcs / 100ml ≤3 Pathogenic bacte...

Embodiment 3

[0051] The blending ratio of step (6) in Example 1 was changed to 300 mg of vitamin C and 3 g of citric acid per 1 kg of 100% pomegranate juice, and the treatment conditions of step (10) were changed to 200MPa ultra-high pressure treatment at room temperature for 240s ; Other operating steps are the same as in Example 1. The test results of the obtained pomegranate juice are shown in Tables 5 and 6.

[0052] Table 5 Physical and chemical indexes of pomegranate juice prepared in Example 3

[0053] project unit of measurement index Soluble solids (20 ℃ , Refractometer method) % ≥12 Total acidity (as citric acid) % ≥0.22 Vitamin C mg / kg ≥400

[0054] Vitamin B 1 mg / kg 0.5 Vitamin B 2 mg / kg 0.3 arsenic mg / kg ≤0.2 lead mg / kg ≤0.5 Food preservatives / no

[0055] Table 6 Microbial indicators of pomegranate juice prepared in Example 3

[0056] project unit of measurement index Total number of colonies Pcs / ml ≤100 Coliform count Pcs / 100ml ≤3 Pathogenic bacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com