A treatment method for deep well polysulfide mud drilling wastewater

A drilling wastewater and treatment method technology, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc., can solve problems such as high content of suspended solids, long cycle, complex composition, etc. achieve high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

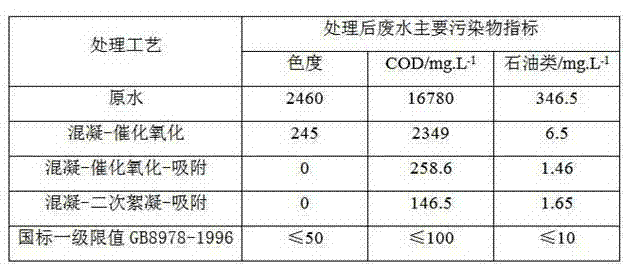

Method used

Image

Examples

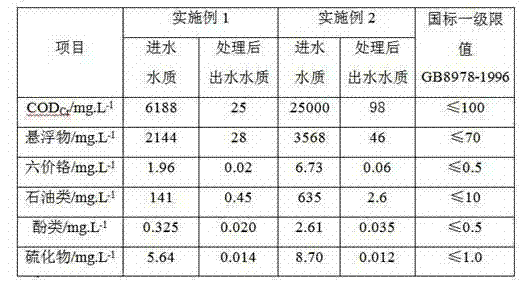

Embodiment 1

[0021] Embodiment 1: get the drilling waste water 10m of the 5600m well depth of certain well 3 , under stirring, add 200kg of coagulant aluminum sulfate, after mixing evenly, add lime to adjust the pH of the wastewater to neutral, add anionic polyacrylamide aqueous solution under slow stirring, the amount of addition is based on the occurrence of flocculent precipitation, and then carry out solidification liquid separation; the filtered treated water is subjected to secondary flocculation, and 50 kg of polyferric sulfate is added under stirring. Precipitation shall prevail, and then solid-liquid separation shall be carried out; the filtered water shall be subjected to adsorption treatment, and the filtered water shall be pumped into the adsorption reactor, and the flow rate shall be controlled at 8.0 m 3 / h, pH=5.0, operating pressure is 0.4Mpa; Adsorb the effluent for oxidation treatment, put 80kg of chlorate oxidant into the oxidation reactor, stir for 4 hours, and carry ou...

Embodiment 2

[0022] Embodiment 2: Get 10m of drilling waste water of the 6300m well depth of a certain well 3 , add 400kg of a mixture of aluminum sulfate and ferrous sulfate under stirring, the mass ratio of the two is 1:1, after mixing evenly, add lime to adjust the pH of the wastewater to 9.5, add anionic polyacrylamide aqueous solution under slow stirring, and its addition amount is The flocculent precipitation shall prevail, and then solid-liquid separation shall be carried out; the filtered treated water shall be subjected to secondary flocculation, and 50 kg of polyferric sulfate shall be added under stirring, and after a uniform reaction, the pH shall be adjusted to neutral with milk of lime, and cationic polyferric sulfate shall be added under slow stirring. Aqueous acrylamide solution, the amount added is subject to the occurrence of flocculent precipitation, and then solid-liquid separation is carried out; the filtered water is subjected to adsorption treatment, and the filtered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com