A method for reuse and treatment of casing processing wastewater

A technology for processing wastewater and casings, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Insufficient depth and other problems, to achieve the effect of feasible industrialization prospects, short wastewater treatment cycle, and outstanding flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

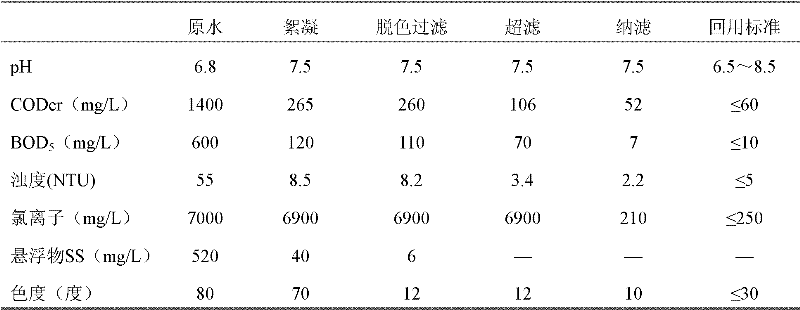

[0058] Casing processing waste water (from a casing processing enterprise in Nantong), collect the waste water into the sump, adjust the pH value of the waste water to 7.5 with dilute sodium hydroxide solution; add chitosan according to the amount of 0.2g / L, and stir first (100r / min) for 5 minutes, and then left to flocculate for 30 minutes, and the supernatant was collected after the wastewater was separated into layers. Compared with raw water, the supernatant obtained by flocculation can achieve 81% removal rate of COD and 90% removal rate of protein.

[0059] Add activated carbon and diatomaceous earth in proportion to the supernatant, the amount of activated carbon added is 2g / L, and the ratio of activated carbon and diatomite is 1:2; after decolorization treatment for 30 minutes, collect the filtrate with a plate and frame filter; plate and frame filter The operating pressure of the machine is 1.8MPa.

[0060] The filtrate is subjected to ultrafiltration treatment with...

Embodiment 2

[0064] Casing processing waste water (from a casing processing enterprise in Nantong), collect the waste water into the sump, adjust the pH value of the waste water to 7.0 with dilute sodium hydroxide solution; add chitosan according to the addition amount of 0.3g / L, first stir (100r / min) for 5 minutes, then left to flocculate for 30 minutes, and the supernatant was collected after the waste water was stratified; compared with the raw water, the supernatant obtained by flocculation had a COD removal rate of 85%, and a protein removal rate of 94%.

[0065] Add activated carbon and diatomaceous earth in proportion to the supernatant, the amount of activated carbon added is 2g / L, and the ratio of activated carbon and diatomite is 1:1; after decolorization treatment for 30 minutes, collect the filtrate with a plate and frame filter; plate and frame filter The operating pressure of the machine is 2.0MPa.

[0066] The filtrate is subjected to ultrafiltration treatment with a cerami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com