Graphene and Fe3O4 nanometer material and preparation method for absorbing high-frequency electromagnetic waves

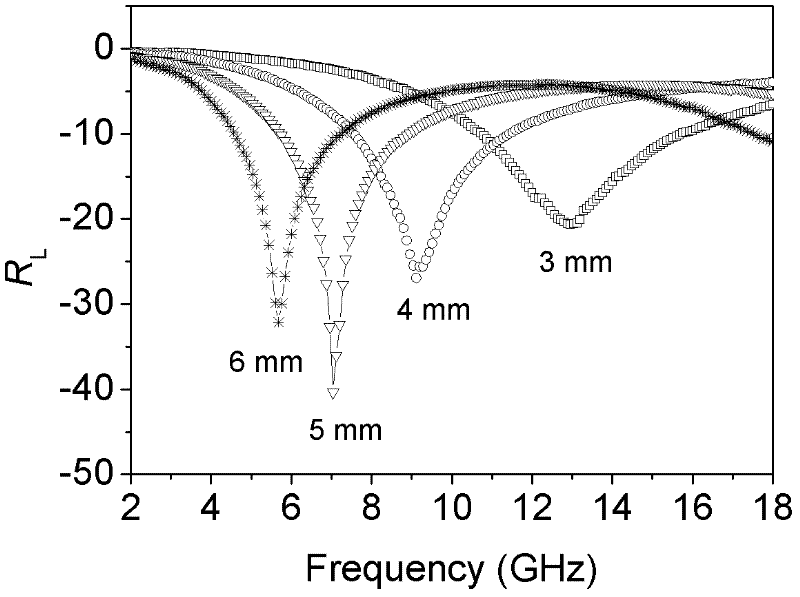

A technology of ferroferric oxide and nanomaterials, which is applied in the field of nanocomposite material preparation, can solve the problems of heavy absorber weight, large amount of addition, and limited application, and achieve the effects of wide application, less material and light material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

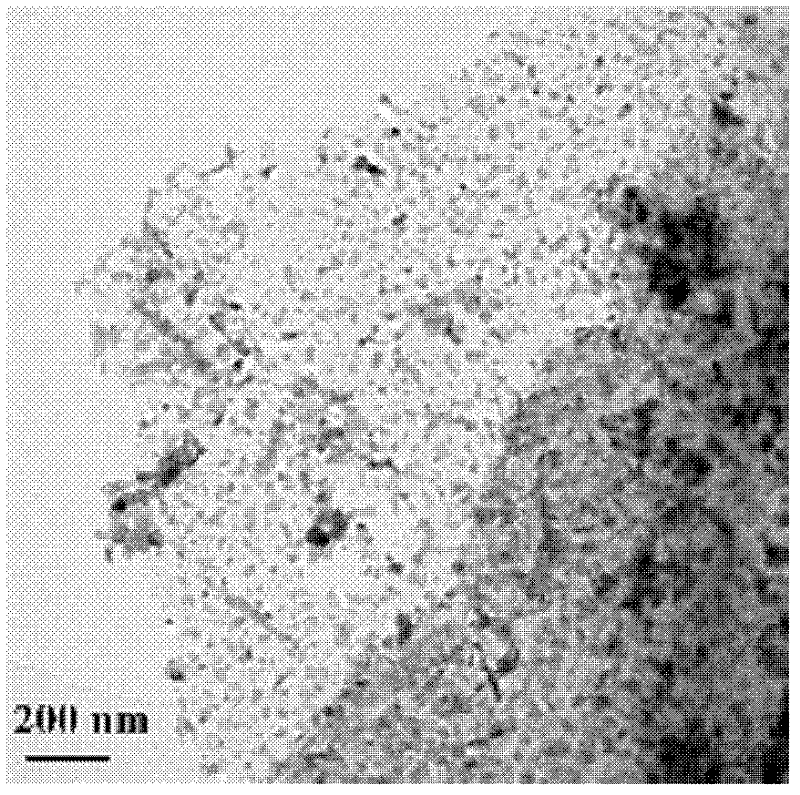

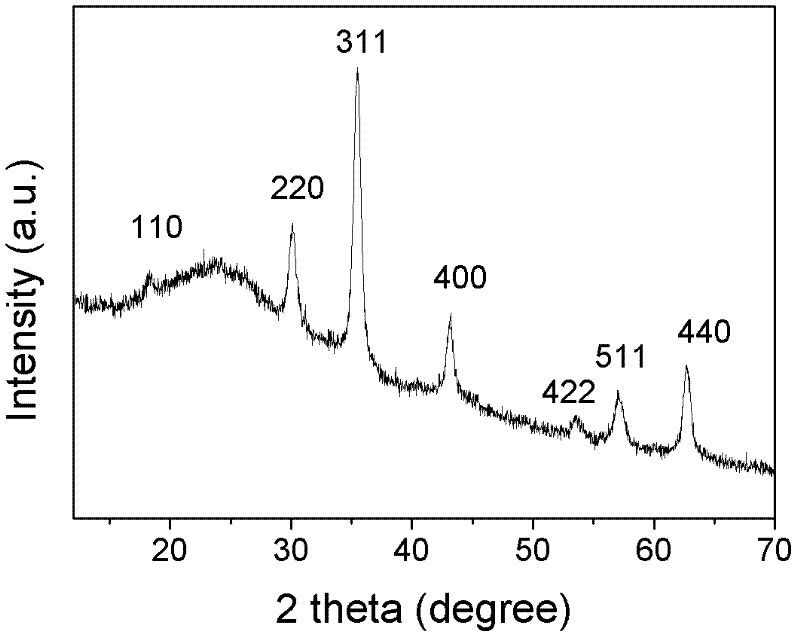

[0021] (1) Take a 500 milliliter beaker, add 280-320 milliliters of water, then add 0.08-0.12 grams of graphene and stir to dissolve and disperse, then add 0.05 grams of Fe(NO 3 ) 3 9H 2 O, and the mixed solution obtained was stirred and reacted for two hours at 50 degrees Celsius in a water bath. After the reaction, cool to room temperature and centrifuge the precipitate in the obtained solution, wash with ethanol and distilled water several times, and dry under vacuum environment.

[0022] (2) The obtained product was heated to 350 degrees centigrade for 2 hours for annealing in an argon atmosphere. After cooling to room temperature, the graphene / Fe3O4 nanocomposite material was prepared by the above process.

Embodiment 2

[0024] (1) Take a 500 milliliter beaker, add 280-320 milliliters of water, then add 0.08-0.12 grams of graphene and stir to dissolve and disperse, then add 0.1 gram of Fe(NO 3 ) 3 9H 2 O, and the mixed solution obtained was stirred and reacted for two hours at 50 degrees Celsius in a water bath. After the reaction, cool to room temperature and centrifuge the precipitate in the obtained solution, wash with ethanol and distilled water several times, and dry under vacuum environment.

[0025] (2) The obtained product was heated to 350 degrees centigrade for 2 hours for annealing in an argon atmosphere. After cooling to room temperature, the graphene / Fe3O4 nanocomposite material was prepared by the above process.

Embodiment 3

[0027] (1) Take a 500 milliliter beaker, add 280-320 milliliters of water, then add 0.08-0.12 grams of graphene and stir to dissolve and disperse, then add 0.15 grams of Fe(NO 3 ) 3 9H 2 O, and the mixed solution obtained was stirred and reacted for two hours at 50 degrees Celsius in a water bath. After the reaction, cool to room temperature and centrifuge the precipitate in the obtained solution, wash with ethanol and distilled water several times, and dry under vacuum environment.

[0028] (2) The obtained product was heated to 350 degrees centigrade for 2 hours for annealing in an argon atmosphere. After cooling to room temperature, the graphene / Fe3O4 nanocomposite material was prepared by the above process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com