Dyeing method of natural fibers in supercritical carbon dioxide fluid

A technology of carbon dioxide and natural fibers, which is applied to the dyeing of natural fibers by disperse reactive dyes and the dyeing and fixing reactions of natural fibers. It can improve the utilization rate, simplify the environmental protection and safety, and have a broad application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The dyed fiber textiles used in this embodiment are pure cotton woven fabrics (102.0g / m 2 ), before dyeing by wet treatment (moisture content 100%); the dye used is disperse reactive red dye (containing a vinyl reactive group, provided by Taiwan Yongguang Chemical Co., Ltd., o.m.f is 0.3%).

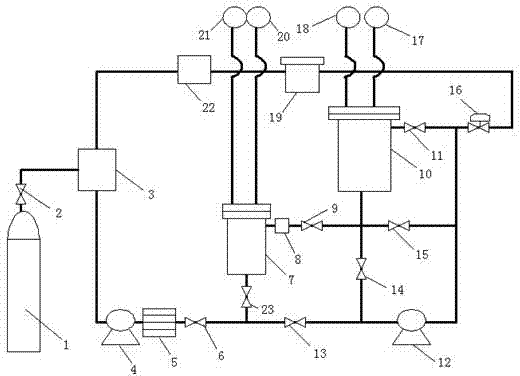

[0019] See attached figure 1As shown, the fabric dyeing steps of the supercritical carbon dioxide fluid used in this embodiment are as follows: firstly, the fabric to be dyed is smooth and uniform, and is wound in a loose state on the dyeing warp beam, and then the outer layer of the wound fabric is covered in advance. Prepared seamless weave mesh wrapping. Open the dyeing kettle 10, place the above-mentioned warp beam with the fabric and a predetermined amount of dye powder in the dyeing kettle 10, and then seal the dyeing kettle 10. After the system is well emptied, close the fine-tuning valve 16 and the shut-off valves 23, 9, 15, open the shut-off valves 2, 6, 13, 14, 11, and ...

Embodiment 2

[0032] This embodiment adopts disperse reactive red dye (containing a vinyl active group, provided by Taiwan Yongguang Chemical Co., Ltd., o.m.f is 0.3%) to dry pure cotton woven fabric (102.0g / m 2 ) for dyeing and color fixing processing. The dyeing process conditions are 23.0MPa supercritical carbon dioxide fluid, the fluid is statically dyed every 10min and then circulates for 1min, the dyeing temperature is 80°C, and the total dyeing time is 120min; the color fixing process conditions are 5.0MPa, 140°C, and three The dosage of ethylenediamine is 2.88g / L, and the color fixing treatment time is 60min.

[0033] Dyeing and fixing of dry cotton woven fabrics with disperse reactive red dye was carried out in the same bath control test, the system pressure was 23.0MPa during color fixing, and other dyeing and color fixing conditions were the same as above.

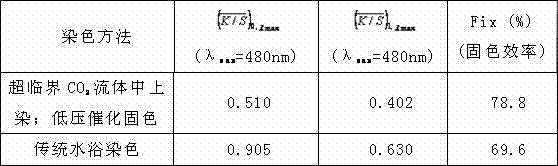

[0034] By the method of embodiment 1, to pure cotton woven fabric (102.0g / m 2 ) under the above conditions to carry out d...

Embodiment 3

[0040] This embodiment adopts disperse reactive red dye (containing a vinyl active group, provided by Taiwan Yongguang Chemical Co., Ltd., o.m.f is 0.3%) to dry pure cotton woven fabric (102.0g / m 2 ) respectively carry out dyeing and color fixing processing. Dye dyeing process conditions are 23MPa supercritical carbon dioxide fluid, fluid static dyeing cycle 1min after every 10min, dyeing temperature is 80°C, total dyeing time is 120min; color fixing process conditions are 23.0MPa, 140°C, color fixing catalyst triethylene The dosage of diamine is 2.88g / L, and the color fixing treatment is 60min. In addition, under the above-mentioned dyeing and color-fixing conditions, a blank test without a color-fixing catalyst was carried out at the same time.

[0041] By the method of embodiment 1, to dry state pure cotton woven fabric (102.0g / m 2 ) under the above conditions to carry out dye uptake and color fixing processing respectively, the specific steps and other conditions are as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com