A kind of polymer solid electrolyte membrane and preparation method thereof

A solid electrolyte membrane and polymer technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of low electrical conductivity, film-forming mechanical deformation, easy leakage, short life and other problems, and achieve high mechanical performance, electrochemical performance. The effect of wide window and low vapor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: In the glove box, weigh 24 grams of lithium bis(trifluoromethylsulfonyl)imide in a 50ml flask, take out the flask from the glove box, add 5ml deionized water and stir evenly at 0°C, while Add 8.84 grams of 1-ethylimidazole dropwise, react for 10 hours, and dry to obtain a composite ionic liquid, which is put into a glove box for use;

[0032] Step 2: Dissolve 12 grams of poly(vinylidene fluoride-hexafluoropropylene) in 108 grams of N-methyl-pyrrolidone, then add the composite ionic liquid obtained in step 1, and cast to form a film to obtain the target polymer solid electrolyte membrane .

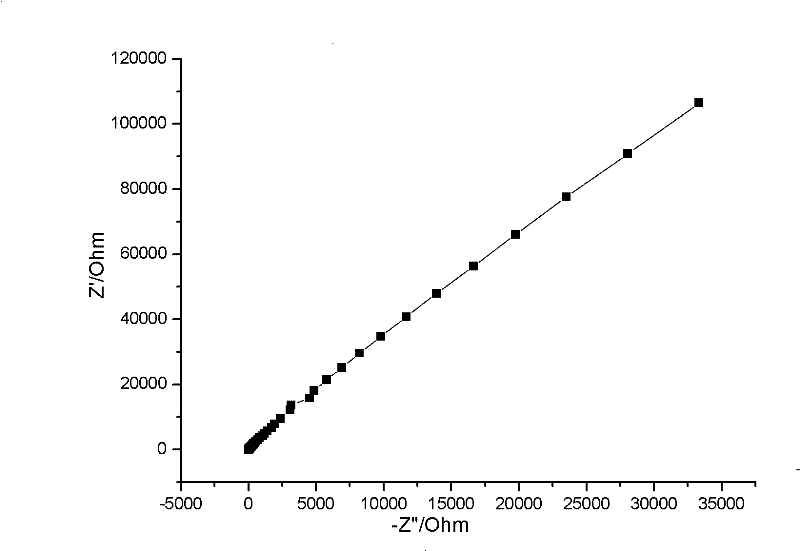

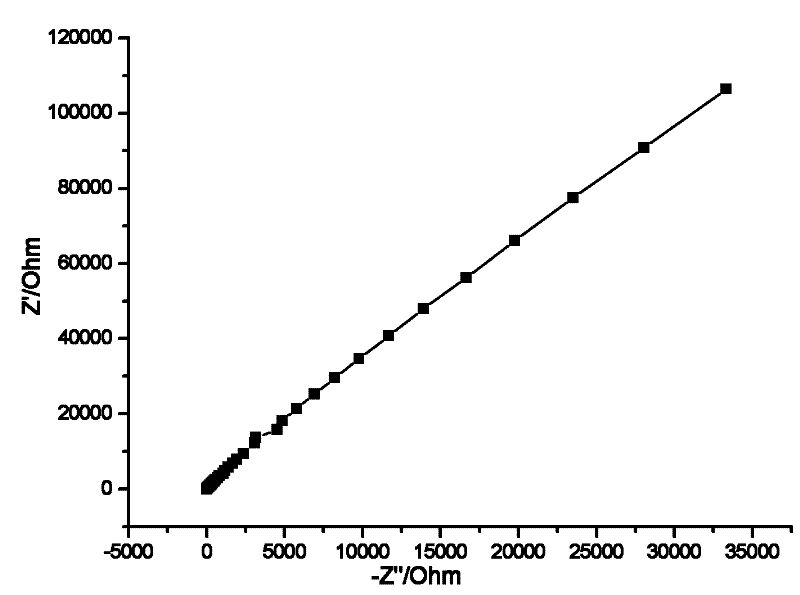

[0033] The appearance of the target polymer solid electrolyte membrane is as follows figure 1 As shown, the AC impedance spectrum as figure 2 As shown, the room temperature ionic conductivity according to the AC impedance test is 2.0mS / cm.

Embodiment 2

[0035] Step 1: In the glove box, weigh 24 grams of lithium hexafluorophosphate in a 50 ml flask, take out the flask from the glove box, add 4 ml of methanol and stir evenly at 0 ° C, while adding 17.75 grams of 1-methylpyrrolidine dropwise, reaction 8 Hour, dry and obtain composite ionic liquid, put into glove box and stand-by;

[0036] Step 2: Dissolve 24 grams of polypyrrole in 130 grams of N,N-dimethylacetamide, take out 30 grams of the solution, add 6 grams of the composite ionic liquid obtained in step 1, stir to form a casting solution, and cast to obtain Target polymer solid electrolyte membrane. According to the AC impedance test, its room temperature ionic conductivity is 2.3mS / cm.

Embodiment 3

[0038] Step 1: In the glove box, weigh 24 grams of lithium tetrafluoroborate in a 50 ml flask, take out the flask from the glove box, add 5 ml of methanol and stir evenly at 0 ° C, and drop 24 grams of 1-methylpyrazole at the same time , after reacting for 7 hours, dry to obtain the composite ionic liquid, put it into the glove box for use;

[0039] Step 2: Dissolve 20 grams of polyoxyethylene in 150 grams of N-methyl pyrrolidone, take out 30 grams of polyoxyethylene solution and add 12 grams of the composite ionic liquid obtained in step 1, stir to form a casting solution, and cast to obtain the target Polymer solid electrolyte membrane. According to the AC impedance test, its room temperature ionic conductivity is 3.4mS / cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com