Production method for special strontium chloride for liquid crystal

A production method and technology of strontium chloride, applied in the direction of calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., can solve the problem of immature barium removal process, unstable product quality, unstable liquid crystal product production, etc. problem, to achieve the effect of good marketing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

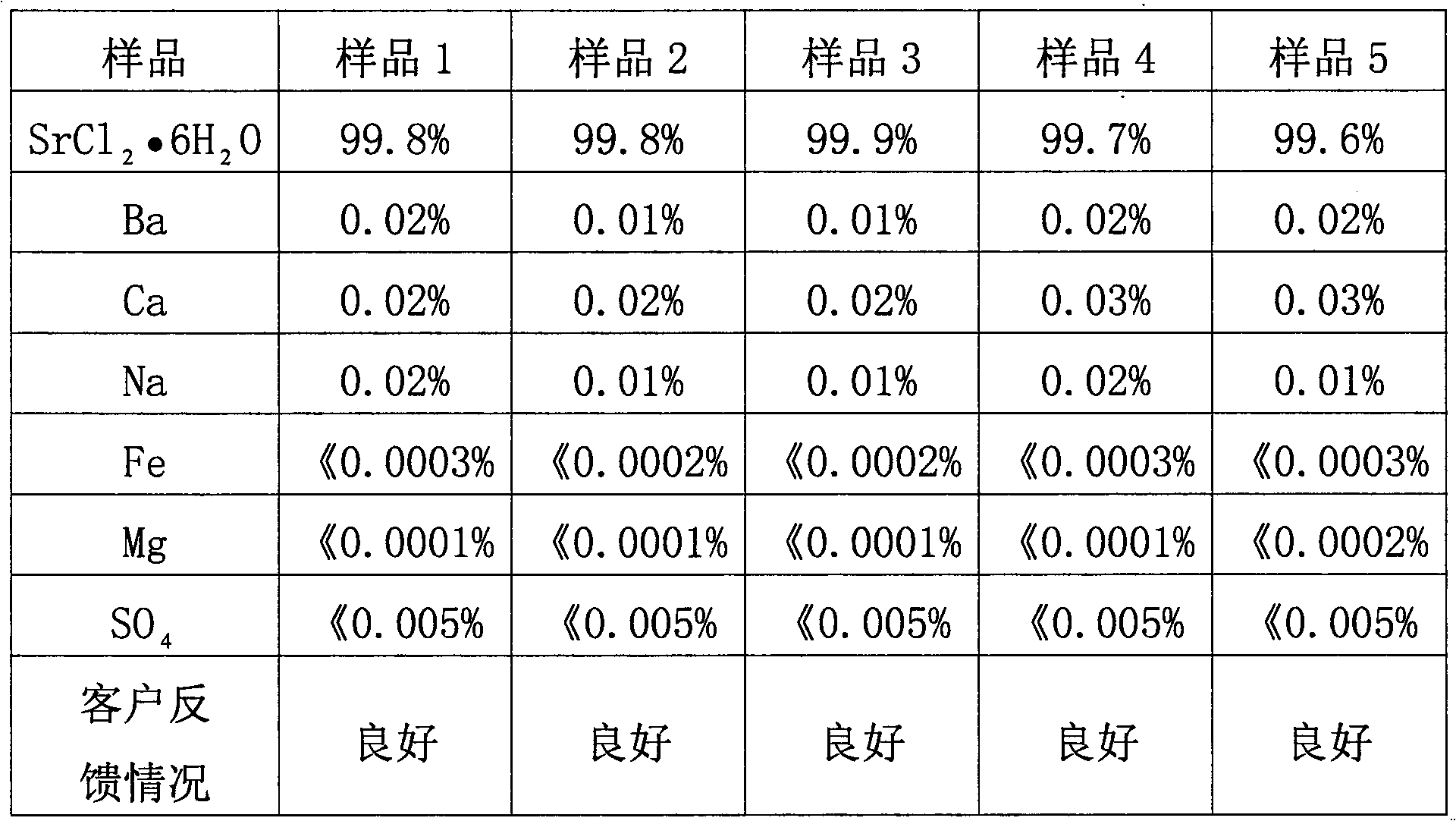

Examples

Embodiment 1

[0039] Using industrial strontium carbonate and hydrochloric acid as raw materials, the resulting solution is concentrated to 40 degrees Baume and cooled to crystallize; the crude strontium chloride is dissolved in pure water, the concentration is adjusted to 40 degrees Baume, the temperature is raised to 95°C, and strontium hydroxide is added as an auxiliary material. Until the pH value of the solution reaches 12, continue to heat up to boiling and let stand for 2 hours, then press filter;

[0040] Then the filtrate was subjected to cooling and crystallization, specifically, the cooling temperature was 9° C., and then the temperature was lowered to cool and crystallize; centrifuged and dried to obtain sample 1.

Embodiment 2

[0042] Use low-grade strontite (strontium with 58% strontium carbonate content, 19% calcium carbonate content and 23% strontium sulfate content) and hydrochloric acid as raw materials to obtain a mixed solution whose main components are calcium chloride and strontium chloride ;

[0043] After preliminary impurity removal, the mixed solution is concentrated to 40 Baume and then cooled to 10°C to crystallize;

[0044] Dissolve the crude strontium chloride in the mother liquor, adjust the concentration to 40 degrees Baume, raise the temperature to 90°C, add strontium hydroxide auxiliary material in a certain proportion until the pH value of the solution reaches 12, continue to heat up to boiling and let stand for 1 hour, filter press;

[0045] Cool and crystallize the press filtrate, specifically to 10°C; then centrifuge, dry and pack to obtain Sample 2.

[0046] Table 1 is the cost analysis table of the per ton product of the present embodiment:

[0047] project

...

Embodiment 3

[0050] Using low-grade strontite (55% strontium carbonate content, 22% calcium carbonate content, 20% strontium sulfate content, other 3%) and hydrochloric acid as raw materials, the main components are calcium chloride and chloride A mixed solution of strontium;

[0051] After preliminary impurity removal, the mixed solution is concentrated to 40 Baume and then cooled to 10°C to crystallize;

[0052] Dissolve the crude strontium chloride in the mother liquor, adjust the concentration to 40 Baume degrees, raise the temperature to 90°C, add strontium hydroxide auxiliary material in a certain proportion until the pH value of the solution reaches 12, continue to heat up to boiling and let stand for 2 hours, filter press;

[0053] The filtrate was cooled and crystallized, specifically cooled to 7°C; then centrifuged, dried and packaged to obtain sample 3.

[0054] Table 2 is the cost analysis table for each ton of products:

[0055] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com