Method for preparing rubber peptizing agent, namely 2,2'-dibenzamido diphenyl disulfide compound

A technology of dibenzamidodiphenyl disulfide compound and diphenylamino disulfide, applied in hydrogenated polysulfide/polysulfide preparation, organic chemistry, etc., can solve the problem of dibenzamidodiphenyl disulfide There are few reports on sulfur synthesis and other problems, and the effects of improving the fluidity in the mold, high product purity and fast reaction speed are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

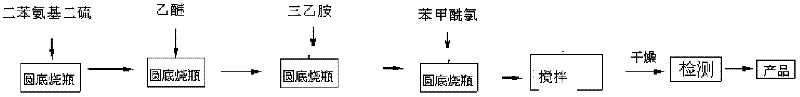

Method used

Image

Examples

Embodiment 1

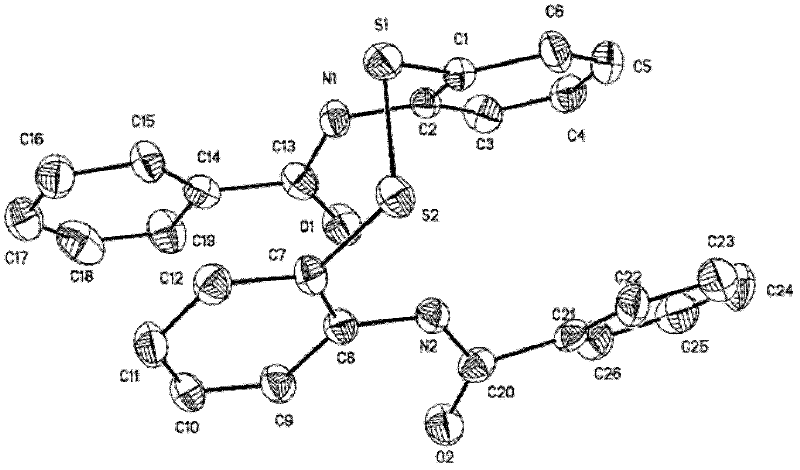

[0025] Add 1.0mmol of diphenylamino disulfide and 5ml of diethyl ether into the reaction flask, stir on a magnetic stirrer, add 2.0mmol of triethylamine, dropwise add 2.0mmol of benzoyl chloride, a yellow precipitate is formed immediately, react for 10min, and filter with suction , drying, yield 83%. The product has a melting point of 134-136°C. The assessment index of gained dibenzamido diphenyl disulfide product is as follows:

[0026] Appearance: light yellow solid

[0027] Melting point (°C) 134-136

[0028] The nuclear magnetic data of gained product is as follows:

[0029] NMR data of dibenzamidodiphenyl disulfide:

[0030] 1 H NMR (400MHz, CDCl 3 , ppm), δ=8.93(b, 2H), 8.50-6.93(m, 18H), 4.24-3.59(m, 6H), 2.68-2.51(m, 2H), \1.78-1.35(m, 30H), 0.89-0.86(m, 3H).

[0031] 13 C NMR (CDCl 3 , 100M, ppm,): δ=164.89, 139.91, 136.71, 136.54, 134.29, 134.25, 132.34, 132.27, 131.99, 128.79, 127.97, 127.50, 124.29, 123.54, 123.51, 120.59,

[0032] Infrared analysis is a...

Embodiment 2

[0038] Add 1.0mmol of diphenylamino disulfide and 5ml of diethyl ether to the reaction flask, stir on a magnetic stirrer, add 2.2mmol of triethylamine, dropwise add 2.2mmol of benzoyl chloride, a yellow precipitate is formed immediately, react for 10min, and filter with suction , drying, yield 87%. The product has a melting point of 134-136°C.

Embodiment 3

[0040] Add 1.0mmol of diphenylamino disulfide and 5ml of diethyl ether into the reaction flask, stir on a magnetic stirrer, add 2.2mmol of triethylamine, dropwise add 2.4mmol of benzoyl chloride, a yellow precipitate is formed immediately, react for 10min, and filter with suction , drying, yield 91%. The product has a melting point of 134-136°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com