Linoleic acid and production technique thereof

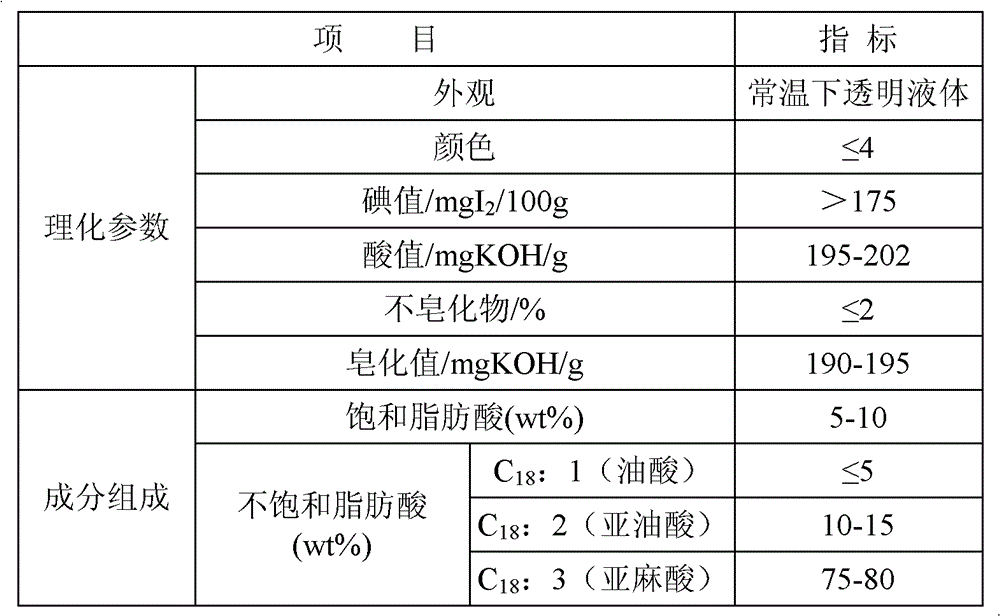

A production process, the technology of linolenic acid, applied in the field of linolenic acid and its production process, can solve the problems of low linolenic acid content and inability to be used in the preparation of ink binders, and achieve high linolenic acid content, short reaction time, and equipment The effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

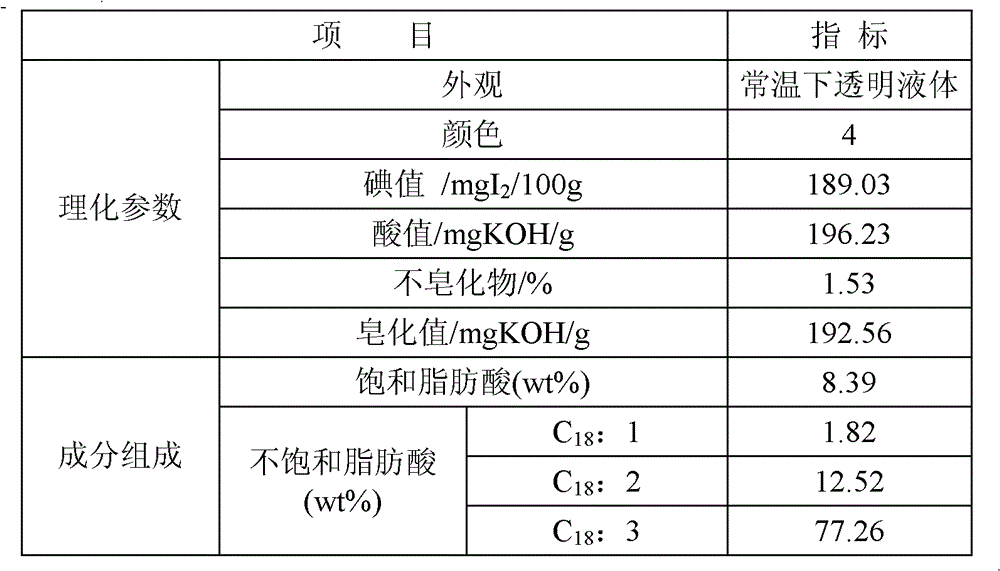

Embodiment 1

[0031] Ingredients: Add 500 kg of sesame oil and 500 kg of deionized water into the reaction kettle, stir and heat up;

[0032] Saponification: Add 320 kg of NaOH solution with a concentration of 25wt% into the reaction kettle, finish adding within 60 minutes, stir and heat, after adding, control the temperature of the material at about 98°C, and react for 4 hours;

[0033] Acidification: After the reactants reach the end of the reaction, add 360 kg of sulfuric acid with a concentration of 40wt% into the reactor, control the addition speed to complete the addition within 60 minutes, stir while adding, and control the reaction temperature of the materials at 40-95 ℃;

[0034] Water separation: After adding sulfuric acid, stir for 15 minutes, then stop stirring, let stand for 8 hours, and let off the waste acid;

[0035] Water washing: Add 600 kg of deionized water at 60°C to the reaction kettle, stir for 15 minutes and let it stand for 4 hours, then turn on the water and repea...

Embodiment 2

[0042] Ingredients: Add 500 kg of flax oil and 1000 kg of deionized water into the reaction kettle, stir and heat up;

[0043] Saponification: Add 360 kilograms of NaOH solution with a concentration of 28wt% into the reactor, finish adding within 45 minutes, stir and heat, control the temperature of the material at about 92°C, and react for 8 hours;

[0044]Acidification: After the reactants reach the end of the reaction, add 360 kg of sulfuric acid with a concentration of 50wt% into the reaction kettle, control the addition speed to complete the addition within 45 minutes, stir while adding, and control the reaction temperature of the materials at 40-95°C ;

[0045] Water separation: After adding sulfuric acid, stir for 15 minutes, then stop stirring, let stand for 10 hours, and let go of the waste acid;

[0046] Water washing: Add 630 kg of deionized water at 70°C to the reaction kettle, stir for 15 minutes and let it stand for 5 hours, then turn on the water and repeat the...

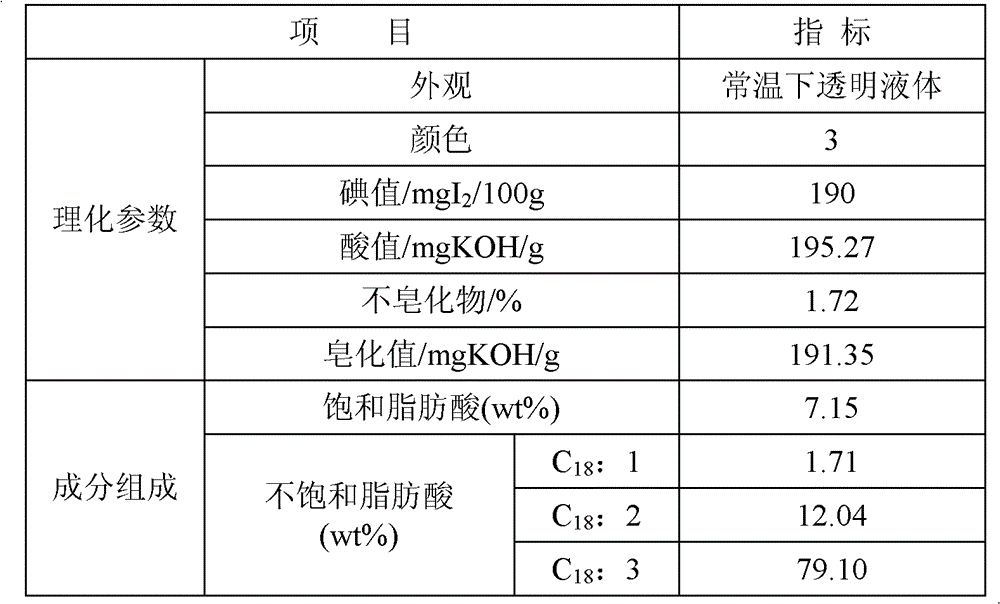

Embodiment 3

[0052] Ingredients: Add 500 kg of flax oil and 1500 kg of deionized water into the reaction kettle, stir and heat up;

[0053] Saponification: Add 400 kg of NaOH solution with a concentration of 30wt% into the reaction kettle, add it in 30 minutes, stir and heat, control the temperature of the material at about 85°C, and react for 10 hours;

[0054] Acidification: After the reactants reach the end of the reaction, add 360 kg of sulfuric acid with a concentration of 60wt% into the reactor, control the addition speed to complete the addition within 30 minutes, stir while adding, and control the reaction temperature of the materials at 40-95°C ;

[0055] Water separation: After adding sulfuric acid, stir for 15 minutes, then stop stirring, let stand for 14 hours, and let go of the waste acid;

[0056] Water washing: Add 570 kg of deionized water at 80°C to the reaction kettle, stir for 15 minutes and let it stand for 6 hours, then turn on the water and repeat the above operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com