Array tube type auto-respiration direct methanol fuel battery system

A methanol fuel cell, self-breathing technology, applied in fuel cells, fuel cell additives, fuel cell components, etc., can solve the problem that the output control of battery pack assembly cannot be comprehensively considered and effectively solved, and the miniaturization of batteries The battery specific power density is unfavorable, expensive cathode and anode materials, etc., to achieve the effect of flexible power design, compact structure, convenient and flexible disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

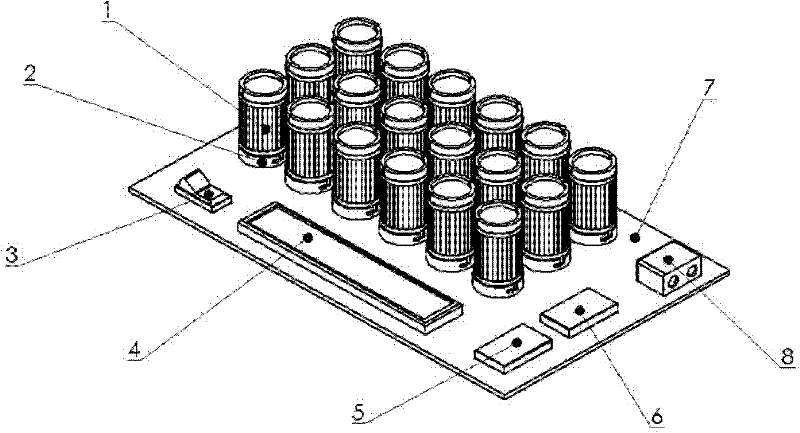

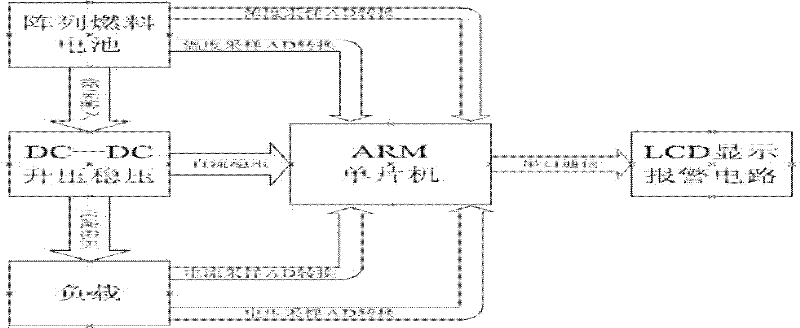

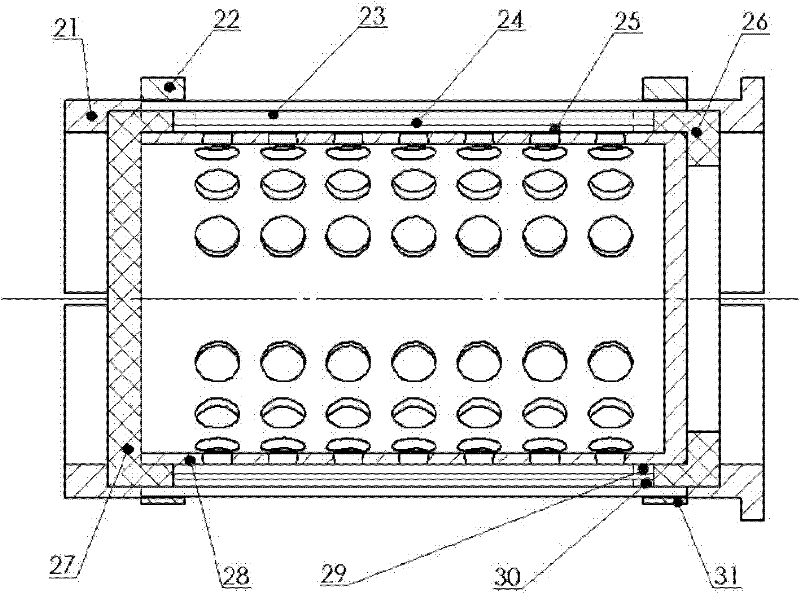

[0032] Such as figure 1 As shown, the array tubular self-breathing direct methanol fuel cell system of the present invention includes a substrate 7 (PCB board), a battery pack and its operating system, and the battery pack is composed of a plurality of cell modules 1 . Such as image 3 As shown, the battery cell module 1 sequentially includes a cathode plate layer 21 ( Figure 5 is a structural perspective view), cathode diffusion layer 23, membrane electrode 24, anode diffusion layer 25, anode plate layer 28 ( Figure 4 is a structural perspective view), the peripheral wall of the anode plate layer 28 is evenly distributed with through holes; one end of the anode plate layer 28 is provided with a polytetrafluoroethylene insulating cover 27, and the other end of the anode plate layer 28 is provided with a polytetrafluoroethylene insulating cover. Tetrafluoroethylene insulating ring 26, the anode plate layer 28 and the cathode plate layer 21 are insulated from each other, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com