Preparation method of collagen polypeptide chelated calcium

A technology of collagen polypeptide and chelated calcium, which is applied in the field of synthesis of food additives and calcium supplements, can solve the problem of less calcium chelated by collagen polypeptide, and achieve the effects of increasing added value, reducing pollution, and being easy for human body to absorb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

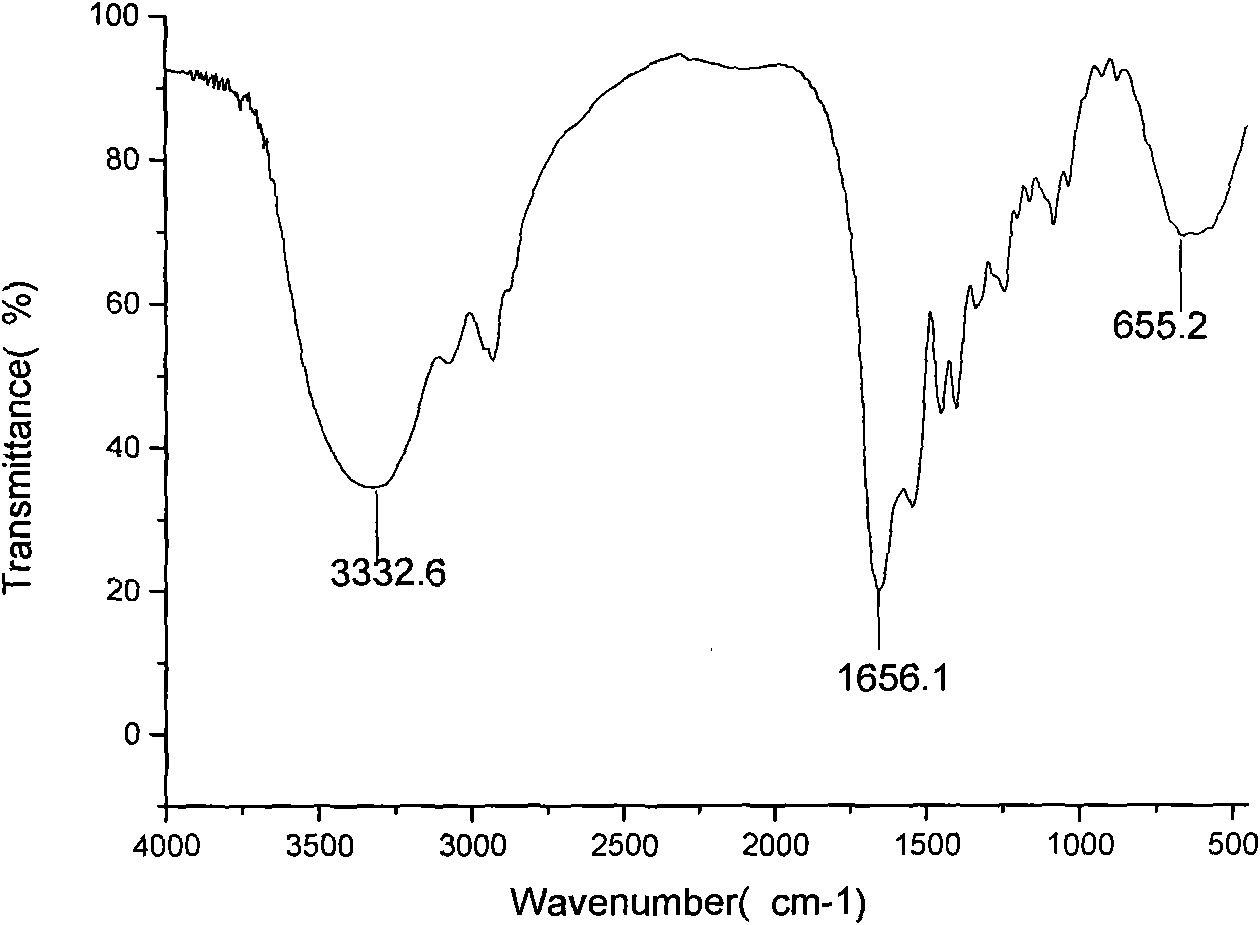

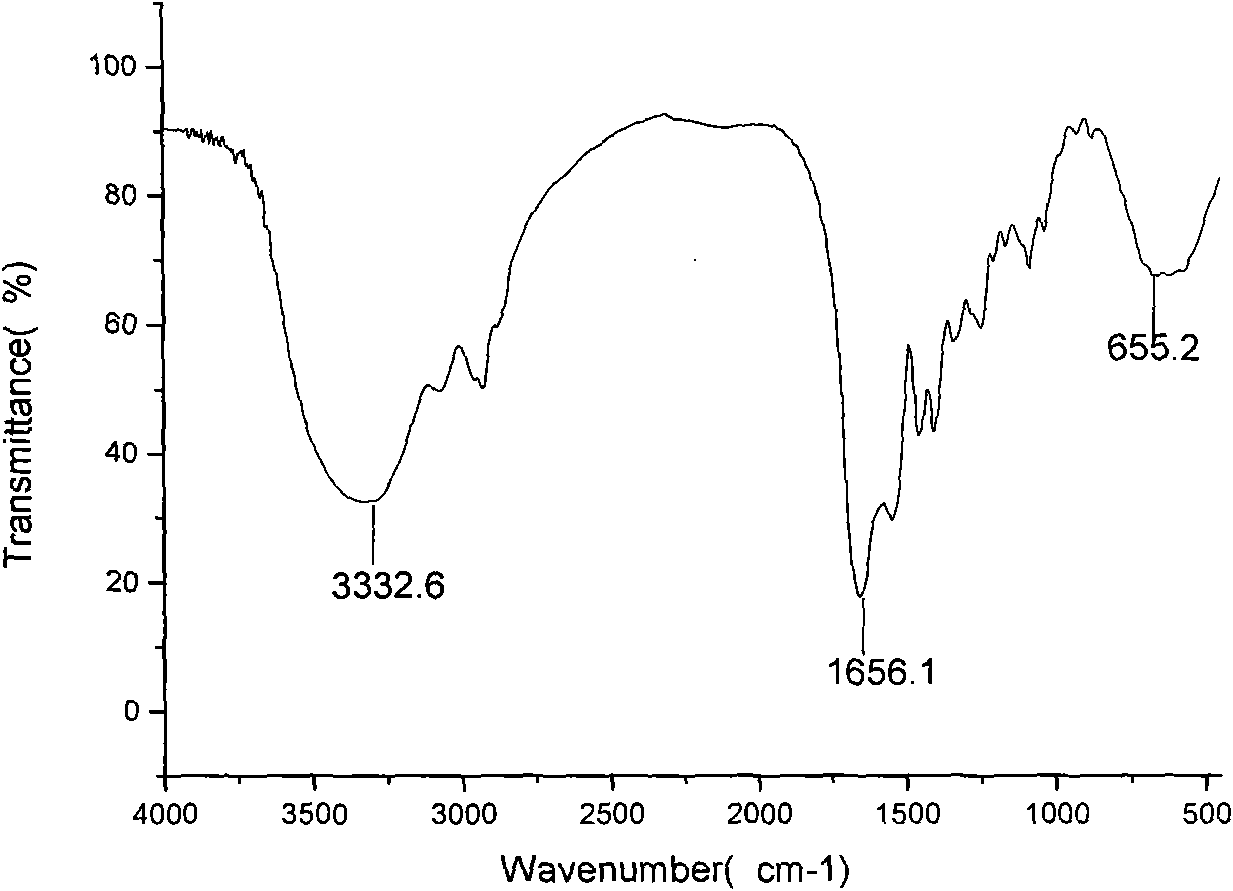

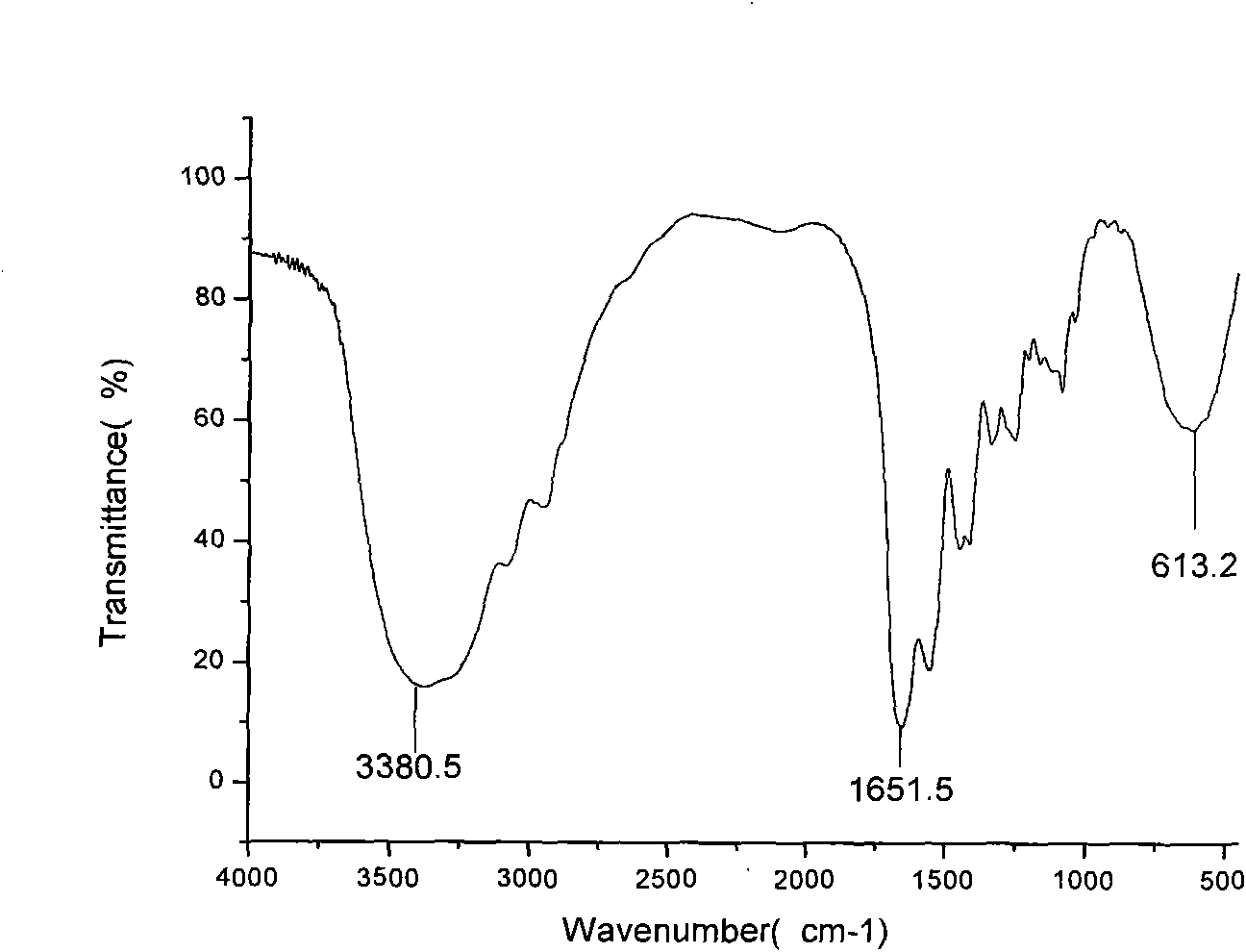

Method used

Image

Examples

Embodiment 1

[0028] (1) Select 100g of food-grade pigskin gelatin, gelatin to water mass ratio of 1:8, swell for 30 minutes, dissolve in a boiling water bath, adjust temperature to 50°C, pH 5.0, add compound protease (Protamex) 1.5 according to the enzyme-material ratio of 1.5% g, enzymatic hydrolysis for 3 hours; after inactivating the enzyme in a boiling water bath for 10 minutes, adjust the temperature to 55°C, pH 6.0, and the ratio of enzyme to material to 5 LAPU / g, add flavor protease (Flavourzyme), enzymolysis for 3 hours, inactivate the enzyme in a boiling water bath for 10 minutes, and obtain small Molecular weight collagen peptide solution;

[0029] (2) Add food-grade calcium chloride to the small molecule collagen polypeptide obtained above for chelation. The chelation conditions are: temperature 20°C, pH 6.0, adding ratio of 110mg calcium ion / g collagen polypeptide, water bath chelation 30min, after the chelation is completed, precipitate with absolute ethanol, centrifuge to rem...

Embodiment 2

[0033] (1) Choose food grade fish skin gelatin 100g, gelatin and water mass ratio is 1: 10 swelling 30min, after boiling water bath dissolves, adjust temperature 50 ℃, pH 6.0, add compound protease (Protamex) 1.5 according to enzyme material ratio is 1.5% g, enzymatic hydrolysis for 3 hours, after inactivating the enzyme in a boiling water bath for 10 minutes, adjust the temperature to 55°C, pH 6.0, and the ratio of enzyme to material to 10 LAPU / g, add flavor protease (Flavourzyme), enzymolysis for 3 hours, inactivate the enzyme in a boiling water bath for 10 minutes, and obtain small Molecular weight collagen peptide solution;

[0034] (2) Add food-grade calcium lactate to the small molecule collagen polypeptide obtained above for chelation. The chelation conditions are: temperature 30°C, pH 6.0, adding ratio of 130mg calcium ion / g collagen polypeptide, chelation in water bath for 30min After the chelation is completed, precipitate with absolute ethanol, centrifuge to remove ...

Embodiment 3

[0037] (1) Choose 100g of pharmaceutical grade cowhide gelatin, the gelatin to water mass ratio is 1:12, after swelling for 30min and dissolving in a boiling water bath, adjust the temperature to 40°C, pH 7.0, add compound protease (Protamex) 0.5 according to the enzyme material ratio of 0.5% g, enzymatically hydrolyze for 6 hours, inactivate the enzyme in a boiling water bath for 10 minutes, adjust the temperature to 60°C, pH 7.0, according to the enzyme material ratio of 20LAPU / g, add flavor protease (Flavourzyme), enzymolyze for 4 hours, inactivate the enzyme in a boiling water bath for 10 minutes, and obtain Collagen peptide liquid with small molecular weight;

[0038] (2) Add food-grade calcium gluconate to the small molecule collagen polypeptide obtained above for chelation. The chelation conditions are: temperature 50°C, pH 5.0, adding ratio of 70mg calcium ions / g collagen polypeptide, water bath chelation After 10 minutes, after the chelation is completed, precipitate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chelation rate | aaaaa | aaaaa |

| Chelation rate | aaaaa | aaaaa |

| Chelation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com